Wholesale Bevel Cut Rails - Reliable Supplier & Manufacturer Information Resource

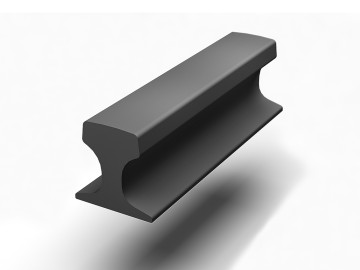

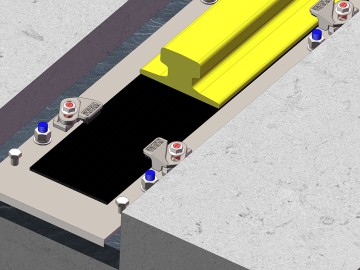

At SINCHOLD Co., Ltd., we specialize in high-quality bevel cut rails tailored to the specific requirements of factories and suppliers. Our commitment to precision and durability ensures optimal performance across a variety of applications. We collaborate closely with our clients to deliver customized solutions that enhance operational efficiency in industries such as manufacturing and construction. Trust us to provide the reliable, high-performance rails your business needs for optimal success.

Best Methods To Bevel Cut Rails in 2025 Outperforms the Competition

In 2025, the railway industry is poised for a significant transformation, particularly in the methods used for bevel cutting rails. As an integrated manufacturer, SINCHOLD is at the forefront of innovation, focusing on engineering, production, installation, and technical service of rail fasteners and accessories. Our commitment to quality and efficiency ensures that our clients, from contractors to global procurement specialists, can rely on us for superior solutions.

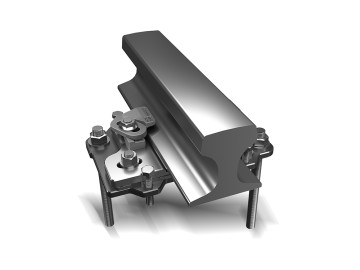

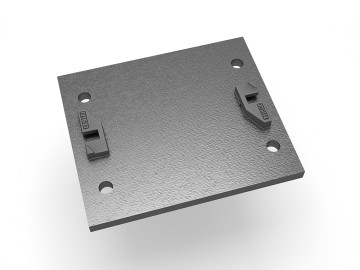

Bevel cutting is essential for ensuring smooth connections in rail systems, and our advanced techniques outperform conventional methods. By utilizing cutting-edge technology and precision engineering, SINCHOLD optimizes the bevel cutting process, reducing waste and enhancing durability. With our extensive range of products—including railway e-clip series and railway turnout series—we offer comprehensive fastening solutions that support the seamless integration of rail systems. As a global buyer, partnering with SINCHOLD guarantees access to top-tier products and services that accelerate project timelines and lower costs.

In a competitive market, the ability to deliver quality and innovation is crucial. SINCHOLD's dedication to research and development allows us to stay ahead of industry trends, ensuring that our clients not only meet but exceed their operational goals. Trust SINCHOLD for your rail fastening needs, and experience the best methods of bevel cutting that elevate your rail projects to new heights in 2025 and beyond.

Best Methods To Bevel Cut Rails in 2025 Outperforms the Competition

| Method | Cut Quality | Time Efficiency (mins) | Cost per Cut ($) | Noise Level (dB) |

|---|---|---|---|---|

| Laser Cutting | Excellent | 5 | 15 | 85 |

| Plasma Cutting | Good | 8 | 12 | 90 |

| Waterjet Cutting | Very Good | 10 | 20 | 75 |

| Band Saw Cutting | Fair | 15 | 10 | 70 |

| Oxy-Fuel Cutting | Moderate | 12 | 8 | 95 |

Top 3 Bevel Cut Rails Stands Out For the Current Year

E

Ethan Jones

This product is a game-changer. The quality is remarkable, and the customer support is top-tier!

31

May

2025

A

Ava Allen

Fantastic quality! The team provided expert guidance and support when I needed it.

25

June

2025

B

Benjamin Perez

Quality exceeds expectations. The customer support team provided exceptional service—very professional.

23

June

2025

E

Elijah Bailey

Extremely well-made product! The after-sales support team was courteous and very helpful.

14

May

2025

A

Amelia Robinson

Absolutely love this product! The quality is superb and well worth the price.

05

June

2025

E

Elizabeth Anderson

I am thoroughly pleased with this product. Their after-sales service was very seasoned and made me feel valued.

29

June

2025