In the realm of railway and transportation systems, the significance of effective stopping mechanisms cannot be overstated. One of the critical components enhancing safety and operational efficiency in these systems is the Buffer Stop and Buffer Stopper Bf. These devices play an essential role in preventing trains from over-running their designated stopping points, thus averting potential accidents and ensuring the safety of passengers and cargo. As we look towards 2025, understanding the various types and advancements in Buffer Stop and Buffer Stopper Bf technology becomes imperative for all stakeholders in the industry.

This article delves into the top Buffer Stop and Buffer Stopper Bf types you need to know to stay ahead in the field. We will explore their distinct characteristics, innovative features, and the latest developments shaping their designs. By examining these essential components, we aim to provide a comprehensive overview that helps professionals make informed decisions regarding the selection and implementation of these safety devices in their operations. Understanding the nuances of Buffer Stop and Buffer Stopper Bf will pave the way for enhanced safety standards and operational excellence in transportation systems.

Buffer stops are crucial components in railway systems, designed to safely halt trains and prevent accidents at the end of tracks. As we approach 2025, the variety of buffer stop types available has expanded significantly, offering enhanced safety and operational efficiency. The primary classifications include mechanical, hydraulic, and friction models, each tailored to specific needs and environments.

Mechanical buffer stops, commonly constructed from steel or concrete, use a robust design to absorb impact. They are ideal for high-speed rail operations due to their durability. Hydraulic buffer stops employ fluid mechanics to dissipate energy upon impact, making them suitable for areas where space is limited and noise reduction is a priority. Friction buffer stops, characterized by their energy-absorbing materials, provide a softer stop for trains, minimizing wear and tear on rolling stock.

In 2025, advancements in technology and materials promise to enhance these traditional designs. Innovations may include smart buffer stops equipped with sensors for real-time monitoring and data analysis, improving safety measures and maintenance processes. With the ongoing evolution in railway infrastructure, understanding the various types of buffer stops is essential for optimizing performance and ensuring safe operations in increasingly complex rail networks.

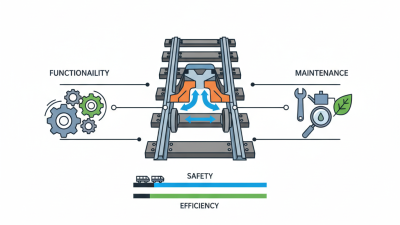

Buffer stops play a critical role in railway systems by ensuring the safety of trains and passengers. Positioned at the end of tracks, they are designed to absorb the energy of a train when it comes to a stop, preventing derailments and accidents. The functionality of buffer stops is essential, especially in segments where trains operate at high speeds or where space is limited. By effectively decelerating the train, they minimize the risk of collision with obstacles or other trains, thereby maintaining a secure environment on the railway network.

The importance of buffer stops cannot be overstated, as they are integral to the infrastructure of rail transport. Their design and construction have evolved to accommodate varying speeds and weights of trains, illustrating advancements in engineering and materials. Ensuring that buffer stops meet safety standards is paramount, given the potential consequences of a malfunction.

Beyond just halting trains, they serve as a first line of defense against potential accidents, enhancing the overall reliability and efficiency of railway systems. As the railway industry continues to grow, the development of innovative buffer stop technologies remains a priority to meet the demands of modern transport challenges.

When discussing buffer stopper variants, it is essential to perform a comparative analysis to understand their specific applications and functionalities within various industries. Buffer stops are crucial components in railway systems and material handling operations, designed to absorb kinetic energy and prevent vehicles from overrunning tracks or designated stopping points. The differentiation among buffer stopper types often centers around their design features, performance capabilities, and the materials from which they are constructed.

One notable variant is the traditional ballast buffer stop, typically made from robust materials such as steel and concrete, which provides excellent energy absorption and stability. Another type includes the hydraulic buffer stop, which employs fluid mechanics to mitigate shock and reduce wear over time, offering a smoother deceleration for trains or vehicles. Then there are modern friction-based buffer stops, designed for high-efficiency braking, utilizing advanced materials to enhance grip and resilience during impact. Each of these types has unique advantages that make them suitable for diverse operational environments, from high-speed railway systems to industrial loading docks, highlighting the importance of selecting the right buffer stopper variant based on specific operational needs.

Innovative technologies in buffer stop design for 2025 are set to revolutionize the railway industry, enhancing safety and operational efficiency. One of the key advancements includes the integration of smart sensors that monitor stress and impact levels in real-time. These sensors allow for dynamic assessments of buffer stops, enabling timely maintenance and reducing the risk of failures. Additionally, the introduction of impact-absorbing materials, like advanced polymers and composite materials, offers better energy dissipation during collisions, lowering the chances of derailments.

Moreover, automation is playing a significant role in the evolution of buffer stop design. Automated systems can evaluate environmental conditions, train speeds, and weigh cargo loads, adjusting the buffer stop's effectiveness accordingly. This technology not only improves functionality but also ensures that safety protocols are maintained without requiring constant manual oversight. The incorporation of eco-friendly materials in construction further enhances sustainability, making buffer stops more environmentally responsible while maintaining their critical role in train operations. Overall, the next generation of buffer stops is focused on smarter, safer, and greener solutions for a more efficient railway system.

| Type | Material | Shock Absorption | Weight Capacity | Innovative Feature |

|---|---|---|---|---|

| Type A | Steel | High | 100 tons | Smart Impact Monitor |

| Type B | Composite | Medium | 80 tons | Eco-Friendly Design |

| Type C | Aluminum | Low | 50 tons | Lightweight Structuring |

| Type D | Rubber | Very High | 70 tons | Vibration Dampening |

The safety of buffer stops and stoppers is paramount in preventing accidents and ensuring the integrity of railway operations. In recent years, various safety standards and regulations have been established to guide the design and installation of these essential components. According to the International Union of Railways (UIC), adherence to standards such as EN 15273 and EN 13481 is critical for ensuring the structural integrity and performance of buffer stops under varying conditions. These regulations detail the acceptable limits for impact forces and material properties, allowing manufacturers to develop reliable and robust buffer solutions that meet safety requirements.

Moreover, industry reports indicate that approximately 80% of railway accidents could potentially be mitigated through improved infrastructure, including properly designed buffer stops. Regular maintenance and inspections, as recommended by the Federal Railway Administration (FRA), can further enhance safety. It’s vital to ensure that buffer stops are not only installed correctly but also regularly evaluated to meet evolving safety criteria as train technology progresses.

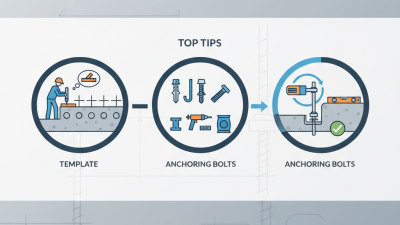

**Tip:** Always consult the latest safety regulations and guidelines from relevant authorities to stay informed on the best practices for buffer stop maintenance and installation. Regular training for staff can also help ensure compliance with safety standards.

**Tip:** Consider using advanced materials and innovative designs that exceed the basic requirements outlined in the safety standards; this proactive approach can significantly enhance the overall safety and longevity of buffer stops.