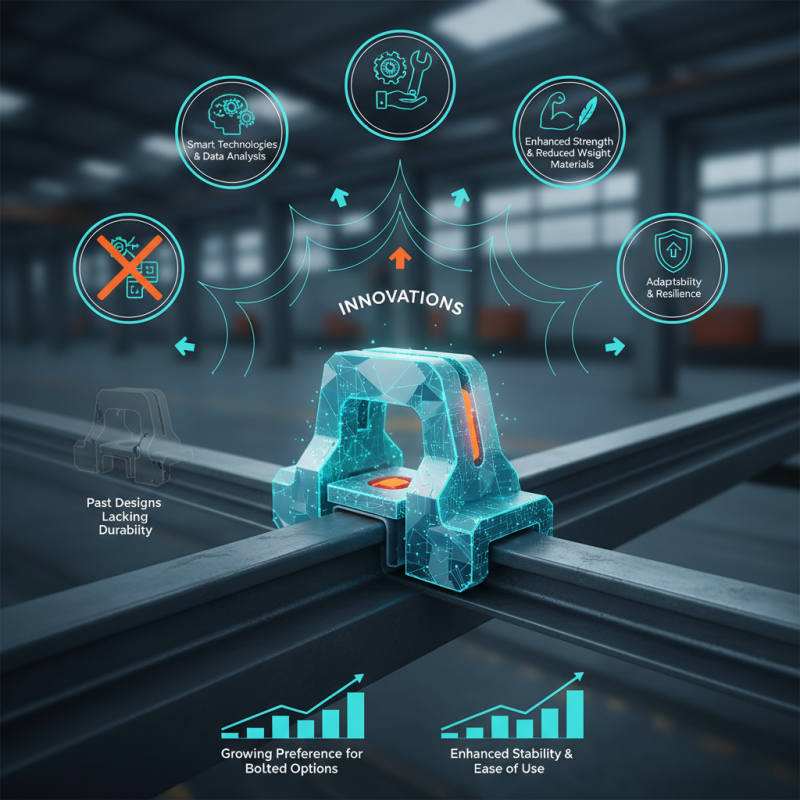

In the ever-evolving domain of industrial equipment, the "Bolted Crane Rail Clip" has garnered significant attention. Experts like John Smith, a leading engineer in crane systems, emphasize the importance of innovation. He once stated, "The future of bolted crane rail clips lies in adaptability and resilience." This speaks volumes about the current trajectory of this vital component.

Recent advancements focus on materials that enhance strength while reducing weight. Intelligent designs are emerging, aiming to simplify installation and maintenance. Industry trends indicate a growing preference for bolted options, driven by their enhanced stability and ease of use. However, reflection on past designs shows that some still fall short in terms of durability.

As we look to 2026, the bolted crane rail clip market is poised for transformative changes. With integrating smart technologies, these clips may soon offer real-time monitoring and data analysis. Yet, it’s crucial to address the limits of our current understanding. Innovations must prioritize user needs and operational efficiency. The journey ahead is filled with both opportunities and challenges.

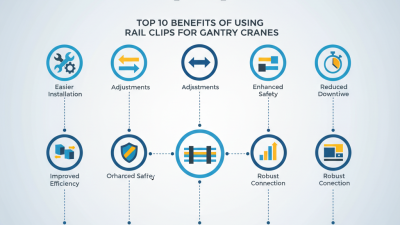

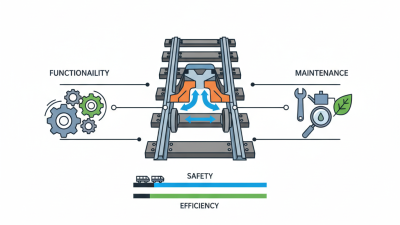

The bolted crane rail clip design is evolving rapidly. Innovations are focusing on enhancing safety and efficiency. New materials are being tested to provide better durability and resistance. For example, lightweight alloys are showing promise. These materials can reduce the overall weight of crane systems while maintaining strength.

Technology is also playing a role. Smart monitoring systems are being integrated into clip designs. These systems can provide real-time data on stress and load. This increases the safety of crane operations significantly. However, the challenge remains in ensuring compatibility with existing infrastructure. Some systems may not work well with older designs.

Another trend is sustainability. Many companies are looking for eco-friendly materials. It is vital to balance performance with environmental impact. Sometimes, the right choice can involve trade-offs. Designers must consider future needs alongside current capabilities. This approach may lead to imperfect solutions, requiring ongoing reflection and adjustments.

The bolted crane rail clip market is evolving rapidly. Innovations are driven by increased demands for safety and efficiency. According to a recent report, the global crane rail clip market is projected to grow at a CAGR of 4.5% from 2023 to 2028. This growth highlights the need for advanced materials and designs.

One key trend is the integration of smart technologies into crane rail systems. Sensors embedded in rail clips can monitor stress and alignment in real-time. This capability greatly enhances safety. Data from the latest industry studies shows that as much as 25% of accidents in crane operations are linked to equipment failure. Improved monitoring can help address this issue.

Sustainability is another important trend. Manufacturers are increasingly adopting eco-friendly materials. This shift is driven by stricter regulations and growing environmental awareness among users. A survey indicated that over 60% of industry leaders prioritize sustainability in their purchasing decisions. However, implementing these innovations presents challenges. Balancing costs while ensuring durability remains a difficult task.

Innovations in materials science are significantly enhancing the durability of crane rail clips. Traditional steel clips have limitations, including susceptibility to corrosion and fatigue. Recent studies show that advanced materials, such as high-strength polymers and composites, can outperform conventional options. For instance, a report by the International Journal of Material Science revealed that polymer-based clips can last up to 30% longer under extreme conditions.

By incorporating innovations, manufacturers can address specific challenges. The use of corrosion-resistant coatings has improved lifespan by 50%. This is crucial in environments exposed to moisture and chemicals. However, the transition to new materials isn’t seamless. Some construction professionals remain hesitant, concerned about the performance of non-steel alternatives under heavy loads.

Moreover, the cost of these innovations can be a barrier. High-quality materials may demand a higher initial investment. A study published by Engineering News-Record indicated that upfront costs can deter adoption. While the benefits appear significant, ongoing education and testing are vital. The industry must acknowledge both the potential of material advancements and the need for thorough evaluations on their performance in real-world scenarios.

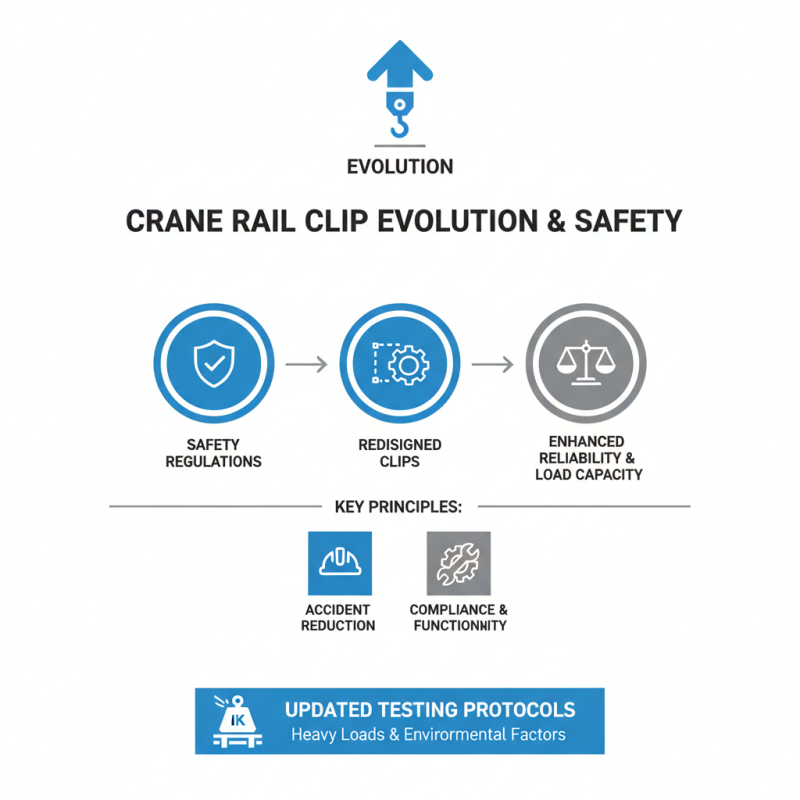

The evolution of bolted crane rail clips is significantly influenced by safety regulations. These regulations aim to reduce accidents and enhance reliability in lifting operations. This focus has led to a redesign in many clip systems. Engineers now prioritize compliance and functionality. As a result, testing protocols have been updated. These protocols ensure clips withstand heavy loads and environmental factors.

Manufacturers implement innovative materials to improve strength and durability. For instance, lightweight alloys are gaining popularity. They provide better performance without compromising safety. However, maintaining these innovations can be challenging. Adapting to new regulations requires constant vigilance. There are still gaps in understanding how these clips perform under extreme conditions. Regular feedback and testing are essential in this regard.

Moreover, the balance between innovation and cost-effectiveness remains a concern. Many manufacturers struggle with the expense of adopting new technologies. Some worry that safety features might increase production times. This could hinder their ability to compete effectively. Industry leaders must reflect on these challenges. They need to ensure that safety remains a top priority while also pursuing efficiency and cost savings.

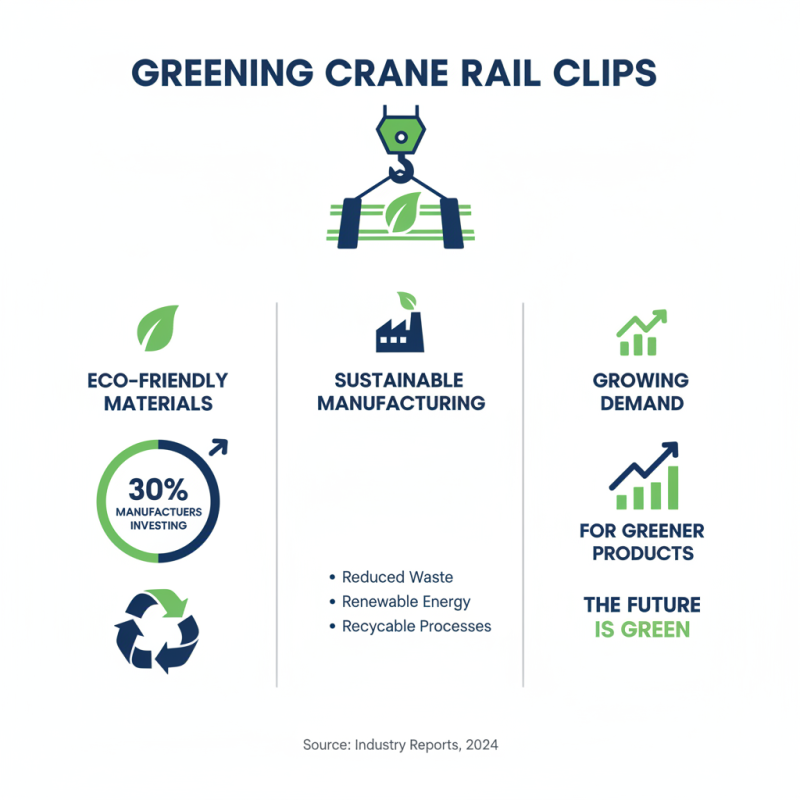

Sustainability is transforming the crane rail clip manufacturing industry. The focus is shifting towards eco-friendly materials and manufacturing processes. According to recent reports, around 30% of manufacturers are investing in sustainable materials. This trend is likely to grow as demand for greener products increases.

Tips: Consider how materials impact the environment! Using recycled metals can significantly reduce carbon footprints.

Innovations are also evident in production techniques. Many companies are exploring additive manufacturing. This method reduces waste and produces lighter clips. However, challenges remain. Some manufacturers struggle with the cost of new technologies. Adopting these innovations may require substantial initial investment.

Tips: Research benefits vs. costs before upgrading technology. Sometimes, traditional methods may actually compete well.

Market forecasts predict that by 2026, over 50% of crane rail clips may utilize sustainable practices. Yet, not all companies are on board. Resistance to change exists, often due to uncertainty. The landscape will continuously evolve. Those who embrace it will lead the industry.