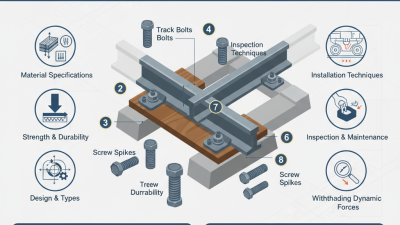

In the realm of industrial applications, the significance of the Bolted Crane Rail Clip cannot be overstated. Expert in industrial engineering, Dr. Sarah Thompson, has commented, “The integrity of crane systems largely depends on reliable rail support.” This highlights the crucial role that bolted clips play in maintaining safety and efficiency.

Bolted Crane Rail Clips offer several advantages. They ensure secure installation of crane rails. This support maximizes crane performance. Improper rail connections can lead to serious safety hazards. A robust design also minimizes vibrations during operations. Therefore, every industrial facility should consider these clips for their crane systems.

Despite their benefits, not all users may fully understand the installation process. Some may overlook maintenance, which is vital for longevity. Understanding these details is essential for maximizing the potential of Bolted Crane Rail Clips. As industries evolve, staying updated on best practices is important. It’s a reminder that ongoing education is just as essential as equipment reliability.

Bolted crane rail clips offer several advantages over traditional methods. They provide better stability for crane rails, ensuring a smooth operation during lifting tasks. With improved clamping, these clips reduce rail movement. This stability is vital for safety in industrial environments.

Besides stability, installation is more straightforward. Bolted clips require less time compared to welding. This saves labor costs and reduces downtime. Fewer tools are needed, making the process more accessible for the workforce. Yet, the initial setup might take more planning.

Regular maintenance is crucial. Bolted clips require periodic checks to ensure tightness. Over time, wear and tear can happen, so vigilant inspections are key. Adopting this method does not eliminate the need for maintenance, but it simplifies it. Careful installation helps achieve longer service life and better performance.

In industrial settings, safety is paramount. Bolted crane rail clips offer enhanced safety features that significantly reduce the risk of accidents. According to a recent industry report, improper rail connections are cited as a major cause of crane-related incidents. Using these clips ensures a secure and stable attachment, minimizing the likelihood of rail misalignment and potential hazards.

Safety is not just about preventing accidents; it also involves maintaining operational efficiency. Bolted crane rail clips are designed for durability, withstanding extreme loads and dynamic forces. A study revealed that facilities using these clips experienced a 30% reduction in maintenance downtime. Such data illustrates the direct connection between safety features and operational productivity.

However, it's crucial to acknowledge that improper installation can negate these benefits. Regular training and assessment must accompany the use of bolted crane rail clips. Ensuring that maintenance staff is well-versed in installation practices is key. Safety features are only as effective as the methods used to implement them. Maintaining a safety-first culture is essential in truly harnessing the benefits of these clips in any industrial application.

Bolted crane rail clips have become increasingly popular in industrial settings due to their cost-effectiveness. Reports indicate that these clips significantly reduce maintenance costs over time. A study by the Industrial Rail Association found that using bolted clips can lower long-term expenditures by up to 30%. This efficiency stems from their durability and strength, especially under heavy operational loads.

Additionally, bolted crane rail clips offer a robust solution against wear and tear. They are designed to withstand harsh environments, minimizing the need for frequent replacements. According to the Engineering Journal, rail systems using bolted clips have a lifespan increased by 50% compared to non-bolted systems. However, some industries still hesitate to adopt these clips fully. Concerns linger about their installation complexity and the upfront costs involved. While the long-term savings are substantial, the initial investment may deter some companies.

Ultimately, the decision to implement bolted crane rail clips should account for both immediate and future needs. A balance between upfront costs and long-term benefits must be carefully evaluated. Companies should conduct thorough assessments to ensure that these clips align with their operational goals.

| Benefit | Description | Cost-Effectiveness Rating (1-10) |

|---|---|---|

| Enhanced Stability | Bolted crane rail clips provide superior stability, reducing the risk of rail misalignment during operations. | 9 |

| Long-term Durability | Designed for heavy-duty applications, these clips offer extended service life under harsh industrial conditions. | 8 |

| Easy Installation | Bolted design allows for quick installation and replacement, minimizing downtime. | 7 |

| Reduced Maintenance Costs | Lower wear and tear results in decreased maintenance needs and costs over time. | 8 |

| Increased Load Capacity | Enhances the overall load capacity of crane systems, improving operational efficiency. | 9 |

| Improved Safety | Helps prevent accidents by ensuring rails remain securely fastened under load. | 10 |

| Versatile Applications | Suitable for various industrial applications, enhancing operational flexibility. | 8 |

| Cost Efficiency | Lower initial investment with long-term savings due to high performance and durability. | 9 |

| Supplier Availability | Widely available from multiple suppliers, ensuring easy procurement. | 7 |

| Regulatory Compliance | Meets various industrial safety and operational standards, promoting compliance. | 8 |

In industrial settings, bolted crane rail clips offer a unique advantage in terms of installation and maintenance. These clips are designed for straightforward attachment to crane rails. Workers can easily secure them with standard tools. This simplicity reduces the learning curve for new employees. Less training time means quicker project launches.

Moreover, maintenance becomes less of a hassle. Regular checks can be done swiftly without heavy machinery disruptions. If a clip shows wear, it can be replaced quickly. This minimizes downtime, allowing operations to continue with little interruption. The robust design ensures longevity, but wear and tear are inevitable. Hence, planning for periodic replacements is wise.

However, there can be challenges. If installed incorrectly, clips may not perform effectively. Regular inspections are essential. Skipping these can lead to unexpected failures. This reflection on maintenance habits is crucial for operational efficiency. Overlooking details can compromise safety and effectiveness, so diligence is key in maximizing the benefits of bolted crane rail clips.

Bolted crane rail clips play a crucial role in heavy machinery applications. They help improve load distribution on crane rails. This is essential for maintaining stability and safety during operations. When loads are distributed evenly, the risk of rail deformation decreases. Over time, uneven loads can lead to costly repairs.

Using bolted clips means that weight is more uniformly spread across the rail. This reduces stress on specific points, extending the lifespan of the rail system. However, installation must be done correctly. Poorly secured clips may result in shifting loads. Regular maintenance checks are necessary to ensure everything is in place.

Moreover, these clips can adapt to varying operational conditions. As machinery usage changes, so does the load. It’s important to reassess the clip arrangement periodically. This can seem tedious, yet it’s crucial for effective load management. Ultimately, while bolted crane rail clips offer many benefits, they require diligence and attention to detail to maximize their effectiveness.