In construction and manufacturing, choosing the right fasteners is critical. Hot Dip Galvanised Bolts are increasingly favored due to their exceptional corrosion resistance. According to a report by the Fastener Industry Association, the demand for galvanized fasteners has surged by 30% in the past five years. This growth highlights the industry's shift towards longevity and reliability.

Expert Maria Thompson, a leading authority in fastener technology, states, "Hot Dip Galvanised Bolts are essential for durable projects. They withstand harsh environments better than standard bolts." Her insights emphasize the importance of quality in fasteners, as structural failures can lead to costly repairs and safety hazards.

While Hot Dip Galvanised Bolts offer significant advantages, one must also consider their limitations. For example, high temperature exposure can affect their performance. Additionally, the initial cost can be higher than traditional options. However, their long-term benefits often outweigh these concerns. As projects evolve, assessing both the benefits and challenges of using Hot Dip Galvanised Bolts becomes crucial for success.

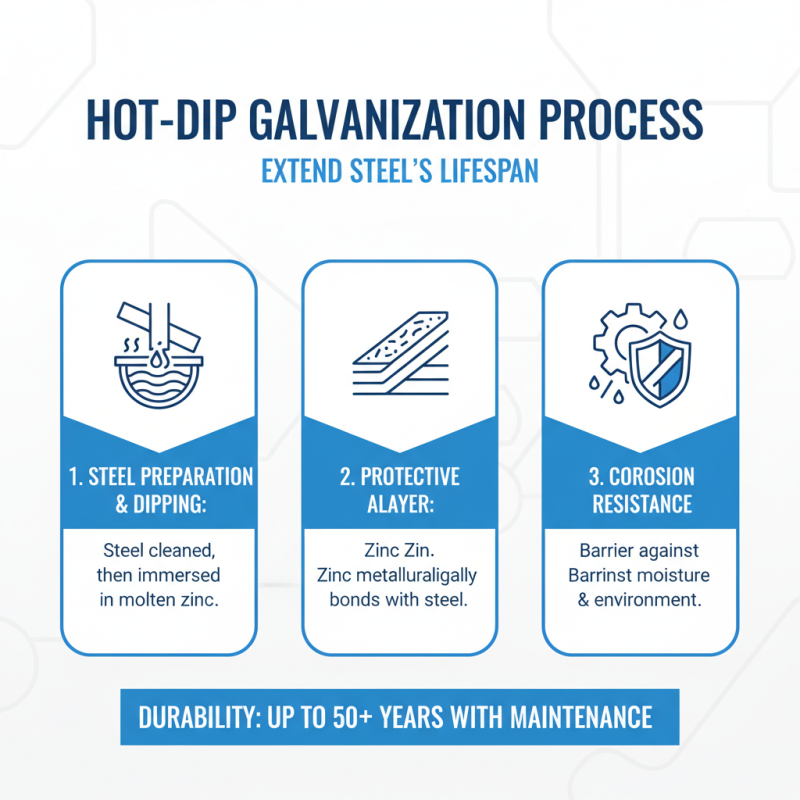

Hot dip galvanization is a process that protects steel from corrosion. The method involves coating steel with molten zinc, forming a durable layer. This layer acts as a barrier against moisture and environmental factors, significantly extending the metal's lifespan. According to a recent industry report, hot dip galvanized products can last up to 50 years or more with proper maintenance.

The benefits of hot dip galvanization are numerous. It creates a stronger bond compared to other coating methods. The zinc's cathodic protection minimizes rust formation, even in scratched areas. Industry studies show that projects using hot dip galvanized bolts experience 60% fewer maintenance needs over their lifetime. For those planning long-term projects, this is a crucial consideration.

Tips: Always inspect for adequate zinc thickness. Inadequate coating may lead to premature failure. Consider the environment where the bolts will be used. Some areas promote faster corrosion, making ideal choices critical.

Remember, not every batch will be perfect. Quality may vary based on production methods. It's vital to request reports on hot dip galvanization quality. Being aware of these variations helps in making informed decisions for your projects.

When choosing hot dip galvanized bolts, several key factors come into play. Coating thickness is crucial. According to industry reports, the average thickness of hot dip galvanization ranges between 50 to 85 microns. This range directly influences corrosion resistance. Thicker coatings can provide extended protection, especially in harsh environments.

Another important aspect is the bolt grade. Common grades include ASTM A325 and A490 for high-stress applications. Data suggests that using the proper grade can improve mechanical strength. The choice of bolt grade impacts the structural integrity of your project.

Additionally, bolt diameter is not to be overlooked. It affects shear strength and load capacity. Ensuring the right fit can prevent catastrophic failures. Many projects have experienced issues due to improper sizing. Pay close attention to specifications, including thread pitch. Small details can make a big difference in performance.

When choosing hot dip galvanized bolts in 2026, several key factors come into play. Look for bolts that ensure durability and corrosion resistance. Hot dip galvanization provides a protective layer, but not all processes are equal. Some bolts may have inconsistent coatings, leading to early wear and tear. Pay close attention to the coating thickness and uniformity.

When selecting the right bolts, consider the project needs. Different models offer diverse benefits. Some bolts are designed for heavy-duty applications, while others excel in lighter settings. Evaluating tensile strength is crucial. A bolt that’s too weak may fail under pressure, causing significant project setbacks.

**Tips:** Always check for supplier certifications. Quality control matters. If possible, seek samples before large purchases. A small test can prevent larger issues later on. An in-depth comparison of models can reveal strengths and weaknesses that aren't immediately obvious. Don't rush your choice. Mistakes can be costly, so take your time to make the best decision.

When it comes to fasteners, the coating type significantly impacts durability. Hot dip galvanizing involves submerging steel in molten zinc. This process results in a thick coating that resists rust effectively. However, it may not be the best choice for all applications. The coating can be uneven, leading to potential weak points. Inspect the bolts carefully before use.

In contrast, other coatings like zinc plating offer a smoother finish. They are less robust but can be suitable for indoor environments. This option is often cheaper and easier to apply. However, it provides less protection against corrosion, especially in wet conditions. Choose your coating based on project requirements. Evaluate the environment where bolts will be used. Some projects may need the strength of hot dip galvanizing, while others can manage with lighter coatings. The decision can greatly affect the longevity of your projects.

Hot dip galvanized bolts are widely used across various sectors due to their exceptional corrosion resistance. In construction, they play a critical role in ensuring structural integrity. For instance, according to the American Society for Testing and Materials (ASTM), hot dip galvanized bolts can withstand exposure to harsh environments, making them ideal for bridges and other outdoor structures. This durability reduces the risk of failure, which is paramount in infrastructure projects.

In the manufacturing sector, hot dip galvanized bolts are often preferred for assembling heavy machinery. They provide excellent strength in high-stress environments. Studies show that these bolts can last up to 50 years when used correctly. However, improper application or poor surface preparation can lead to premature coating failure, undermining their lifespan. It's crucial to ensure that bolts are installed using the right methods to maximize their protective qualities.

Moreover, hot dip galvanized bolts are increasingly popular in agricultural applications. In this sector, they face exposure to moisture and chemical fertilizers. Using these bolts can enhance the longevity of farming equipment. Yet, not all projects may require the advanced properties of hot dip galvanization. It's wise to evaluate whether the added cost aligns with specific project needs. Ultimately, while hot dip galvanized bolts offer robust benefits, careful consideration is necessary for optimal outcomes.