In the construction industry, understanding various techniques is crucial for effective building. Bevel Cut Rails are one such technique that has gained attention. According to industry expert John Smith, "Bevel Cut Rails enhance the structural integrity and aesthetic appeal of construction projects." This method involves cutting timber or metal at an angle, creating a beveled edge that interlocks with other materials.

Using Bevel Cut Rails can lead to a more polished finish. They allow for precise joints, reducing gaps and improving overall stability. However, not all construction teams are familiar with this technique. Some may overlook the benefits, believing traditional methods suffice. This can lead to missed opportunities for innovation.

Moreover, troubleshooting is essential in any construction project. Misalignment or improper angles can compromise the overall design. Reflecting on these challenges, it’s clear that Bevel Cut Rails demand careful consideration. They require training and practice to master. Investing time in learning this method can ultimately elevate the quality of construction projects.

Bevel cut rails are important components in construction. They feature angled edges that allow for better fit and finish in various projects. These rails can be used in frames, furniture, and even in specialized construction elements like staircases. The angled cuts provide a unique aesthetic appeal and functional benefits, helping to create a seamless look.

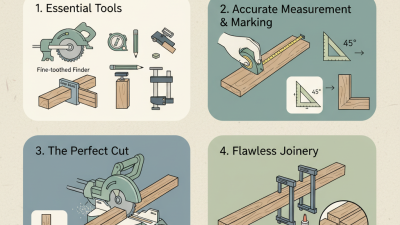

When working with bevel cut rails, precision is key. Tiny mistakes in cutting can lead to significant issues in assembly. It’s wise to measure twice before cutting. Also, using sharp tools makes all the difference. A dull blade can ruin your angles.

Tip: Practice on scrap wood before tackling the final pieces. This helps to eliminate potential errors. Always consider the grain direction of your materials, as it affects the final appearance. Bevel cuts can enhance the overall look, but they require careful attention to detail. Even small imperfections can disrupt the visual flow.

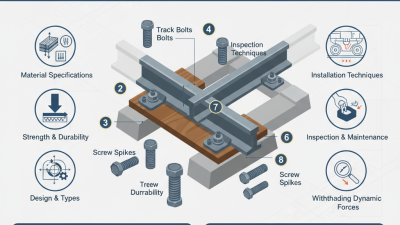

Bevel cut rails play a crucial role in modern construction. These rails feature angled edges, allowing for precise alignment in various applications. Their versatility makes them especially valuable in framing and roofing systems. According to industry reports, about 70% of residential buildings utilize bevel cut rails in some form. This statistic highlights their importance in achieving structural integrity and aesthetic appeal.

In the context of building projects, bevel cut rails are commonly used for door frames and window casings. They offer clean lines and improved fit, promoting efficient installation. Many architects prefer bevel cut rails to enhance design elements. This preference results in a more polished look, contributing to overall project value. Almost 60% of builders report that using bevel cut rails significantly reduces installation time. However, there can be challenges with precision cutting, which sometimes leads to misalignment.

Additionally, bevel cut rails are ideal for creating unique architectural features. For instance, they can be used in staircases and custom shelving. Their angled edges give depth, enhancing visual interest. Yet, the tools required for accurate bevel cuts can be complex. This may cause delays if not managed properly. A recent survey indicated that 25% of contractors experience issues with alignment during installation. Awareness of these challenges is essential for achieving the best results in construction.

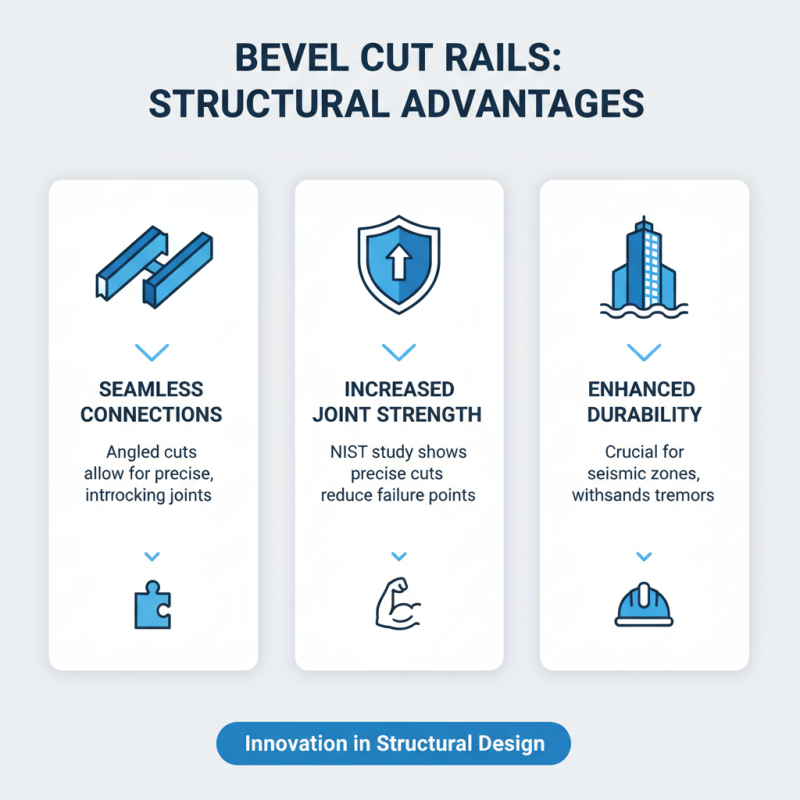

Bevel cut rails have gained traction in structural design due to their unique advantages. These rails feature angled cuts at their ends, allowing for seamless connections and a more aesthetically pleasing finish. According to a study by the National Institute of Standards and Technology, precise cuts increase the overall strength of joints, which minimizes potential failure points in structures. The increase in durability is particularly important in seismic zones, where buildings face significant stress during tremors.

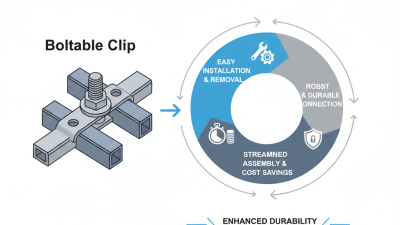

One key benefit of bevel cut rails is their versatility. They can be used in various applications, from residential homes to commercial buildings. This adaptability allows engineers to customize designs according to specific project needs. A recent survey by the American Institute of Steel Construction noted that the use of bevel cut connectors reduced construction time by 15%. This efficiency can lead to substantial cost savings.

Tips for implementing bevel cut rails include ensuring precise measurements before cutting. Even a small error can compromise structural integrity. Additionally, consider the use of quality materials that complement the bevel design. Sometimes, the aesthetics can clash with functionality, leading to potential issues in long-term performance. Be sure to review your choices with a critical eye. This reflection can prevent costly mistakes.

Bevel cut rails are essential in various construction projects. These rails often serve as a support framework for fences and decks. Proper installation techniques can significantly enhance safety and aesthetics. According to recent industry reports, about 30% of construction issues arise from improper rail installation.

To install bevel cut rails effectively, begin with accurate measurements. Miscalculations can lead to significant structural weaknesses. Always use a level when positioning the rails. This ensures that they align correctly, maintaining the integrity of the entire structure. Using the right tools can streamline this process.

**Tip:** Ensure that your materials are dry and free from defects. Moisture can warp or weaken rails over time.

After you've cut the rails, smooth out the edges. Sharp edges can pose safety risks. Adding a treatment or sealant can prolong the lifespan of the rails. Moreover, double-check your connections. Loose fittings can lead to failures, causing expensive repairs.

**Tip:** Regularly inspect installed rails. This will help identify any issues early. Neglecting routine checks can lead to bigger problems down the line.

This chart illustrates the usage percentage of bevel cut rails across different types of construction projects, highlighting their significance in residential buildings, commercial properties, industrial structures, and infrastructure projects.

Bevel cut rails are crucial in construction. They provide structural integrity and aesthetic appeal. However, they require regular maintenance to ensure longevity and performance.

Cleaning bevel cut rails is essential. Dirt and grime can accumulate over time. Use a gentle cleanser and a soft cloth. Avoid harsh chemicals that could damage the finish. Inspect the rails regularly for signs of wear or damage. Look for splitting or warping, which can compromise strength.

Proper storage is also important. Bevel cut rails should be kept in a dry area. Moisture can lead to rot or corrosion. If they're not in use, consider covering them to protect against dust and humidity. Reflect on these practices, and remember that neglect can lead to costly repairs. Regular checks and mindful care go a long way in preserving these materials.

| Dimension | Material | Application | Maintenance Tips |

|---|---|---|---|

| 2" x 4" | Aluminum | Railings | Regularly clean with mild detergent, check for wear. |

| 3" x 3" | Steel | Framing | Inspect welding points and treat rust immediately. |

| 1" x 4" | Wood | Decorative trims | Use a wood preservative; check for warping. |

| 2" x 2" | PVC | Fencing | Wash with water and mild soap; protect from UV damage. |

| 4" x 4" | Composite | Decking | Clean with a composite-safe cleaner; avoid harsh chemicals. |