In the realm of durable construction solutions, Cast-In Fixings play a critical role. According to Dr. Emily Carter, a leading expert in structural engineering, "The stability of modern structures heavily relies on effective anchoring systems." This highlights the importance of integrating precise Cast-In Fixings into construction practices.

These fixings notably enhance the strength of concrete structures. They provide robust support for various applications, such as attaching walls and ceilings. The innovative design allows for seamless incorporation, ensuring that the connections are both reliable and efficient. However, not all projects fully capitalize on their potential. Some builders overlook the significance of proper installation, leading to vulnerabilities.

The construction industry must reflect on these challenges. Mistakes in applying Cast-In Fixings can result in structural weaknesses. Therefore, it is essential to prioritize training and quality assurance. By doing so, construction professionals can create more resilient structures that stand the test of time. The future of building depends on these crucial elements.

Cast-in fixings play a crucial role in modern construction techniques. They provide reliable anchoring solutions that enhance structural integrity. According to a report by the International Federation of Structural Concrete, about 30% of structural failures are due to inadequate anchoring. This statistic highlights the need for robust fixing systems.

When cast into concrete, these fixings form a strong bond. They distribute loads effectively, which is essential for safety. Builders have observed that about 50% of construction projects face delays due to poor fastening systems. This can lead to increased costs and longer timelines. Quality cast-in fixings reduce these risks and promote efficiency.

Still, challenges exist. Some construction professionals underestimate the importance of proper installation. A study indicated that up to 20% of fixings are misaligned, affecting performance. This underscores the need for proper training and awareness. In a field where precision is key, overlooking cast-in fixings can lead to significant setbacks. Proper attention to detail is vital for ensuring a durable construction outcome.

| Dimension | Importance | Application | Advantages |

|---|---|---|---|

| Load Bearing Capacity | Ensures structural integrity and safety | High-rise buildings | Increases lifespan of structures |

| Flexibility in Installation | Facilitates complex architectural designs | Commercial complexes | Saves time and labor costs |

| Durability | Resistant to corrosion and weather | Infrastructure projects | Reduces maintenance frequency |

| Cost-Effectiveness | Minimizes overall project costs | Residential buildings | Improves value for money |

Cast-in fixings are critical in modern construction. They provide structural integrity and support for various building applications. According to industry reports, the global market for cast-in systems is projected to grow by 5% annually through 2027. This indicates a rising demand for efficient and durable construction solutions.

Types of cast-in fixings include anchors, brackets, and sleeves. Anchors, often used in concrete, provide robust support for beams and columns. Brackets are essential for securing facades and cladding systems. Sleeves allow for easy installation of MEP services within concrete elements. Each type serves unique purposes, ensuring versatility on construction sites. Awareness of their applications can lead to better design choices and reduced errors.

Despite their advantages, challenges exist. Misalignment during installation can lead to structural weaknesses. A study found that 20% of construction defects are attributed to installation errors. Projects can be delayed due to these issues. Builders need stringent quality control practices. Addressing these challenges will enhance the benefits of cast-in fixings.

Cast-in fixings play a crucial role in enhancing the structural integrity and longevity of buildings. They serve as robust anchors, embedded directly into the concrete. This integration ensures that the fixings share the load effectively with the surrounding material. Over time, this bond becomes stronger, resisting vibrations and shifts. Without such fixings, structures may face premature failure, leading to costly repairs.

Using cast-in fixings can significantly reduce issues related to corrosion. Unlike surface-mounted options, these fixings are protected from environmental factors. This means less maintenance work for engineers over the years. However, the installation process must be precise. Any misalignment or poor concrete quality can weaken the entire assembly. Regular inspections should also not be overlooked to ensure reliability.

The benefits of cast-in fixings extend beyond just structural support. They contribute to the overall safety of the building. Yet, it's vital to acknowledge that these fixings are not a cure-all. They require mindful planning and execution. Each project has unique demands, and a one-size-fits-all approach falls short. An effective strategy combines these fixings with other solutions for optimal success.

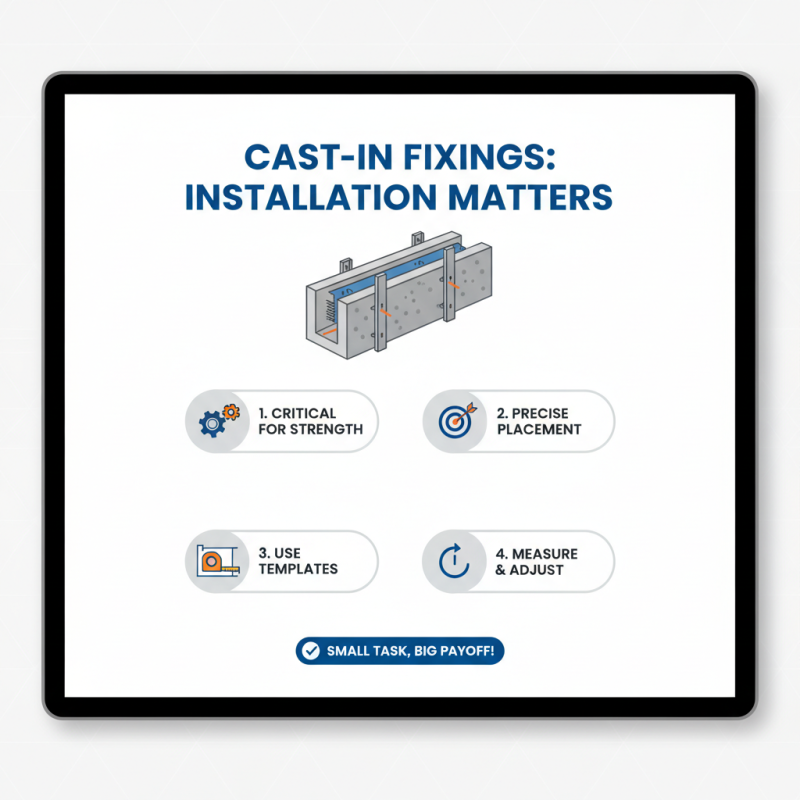

Proper installation of cast-in fixings is critical for a strong structure. The placement must be precise. Misalignment can lead to failure. Before pouring concrete, using templates can ensure accuracy. Take the time to measure and adjust as necessary. It’s a small task that pays off later.

Additionally, care must be taken with the concrete mix. A too-wet mix may weaken the fixings. Conversely, a too-dry mix might not bond well. Monitor the curing process closely. It's vital for the integrity of the fixings. Inspecting the work environment can prevent unexpected issues. Dirt or debris can interfere with proper fixation.

Finally, post-installation checks are essential. Look for any signs of movement. It's not uncommon to overlook small cracks around fixings. They can indicate future problems. Document and reflect on the installation process. Continuous improvement will enhance overall construction quality. This awareness ensures cast-in fixings remain effective over time.

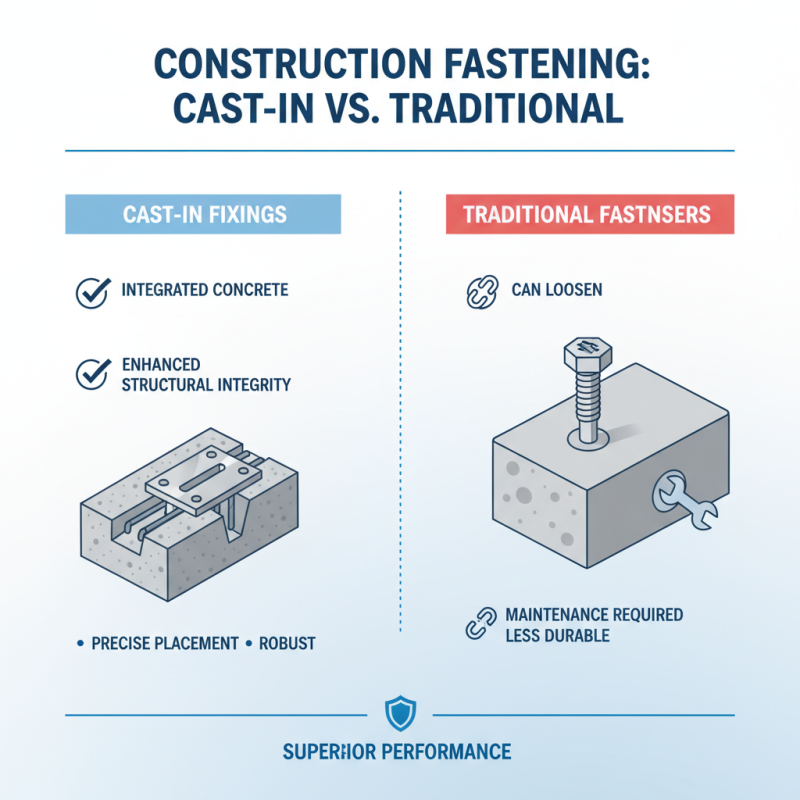

When comparing cast-in fixings with traditional fastening methods, the differences become evident. Cast-in fixings integrate directly into the concrete. This approach enhances structural integrity. The connections are often more robust. They allow for precise placement and load distribution. In contrast, traditional fasteners can loosen over time. They may require constant maintenance.

Installation of cast-in fixings may seem more complex. Yet, they offer lasting durability. Traditional methods might be quicker, but they face performance issues. Over time, screws and anchors could degrade the material. This could lead to safety concerns. The initial ease of use can result in future problems.

Consider the long-term impact of construction choices. Cast-in fixings create a seamless bond with concrete. They reduce the risk of damage caused by rust or corrosion. Traditional fastening methods expose structures to moisture and wear. Building for longevity is essential. Opting for durable solutions now can prevent costly repairs later.