When embarking on construction projects, selecting the right anchoring cements is crucial. These materials ensure durability and stability for various applications. According to a report from Global Market Insights, the anchoring cements market is projected to grow by 7.5% annually through 2027. This growth indicates an increasing demand for high-quality anchoring solutions.

Experts in the industry emphasize the importance of making informed choices. Dr. Emily Chan, a renowned materials engineer, states, "The right anchoring cement can significantly impact the longevity and safety of a structure." This highlights the necessity of understanding product specifications and application methods, as different projects may require distinct anchoring properties.

While there are many products available, not all meet the necessary criteria. Some may perform well in controlled environments but fail under stress. This disparity can lead to future project failures. An informed selection process can prevent such issues, saving both time and resources in the long run.

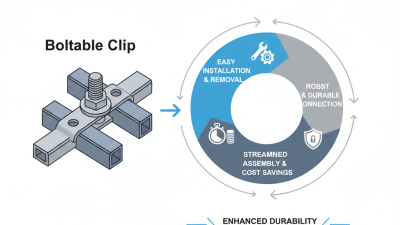

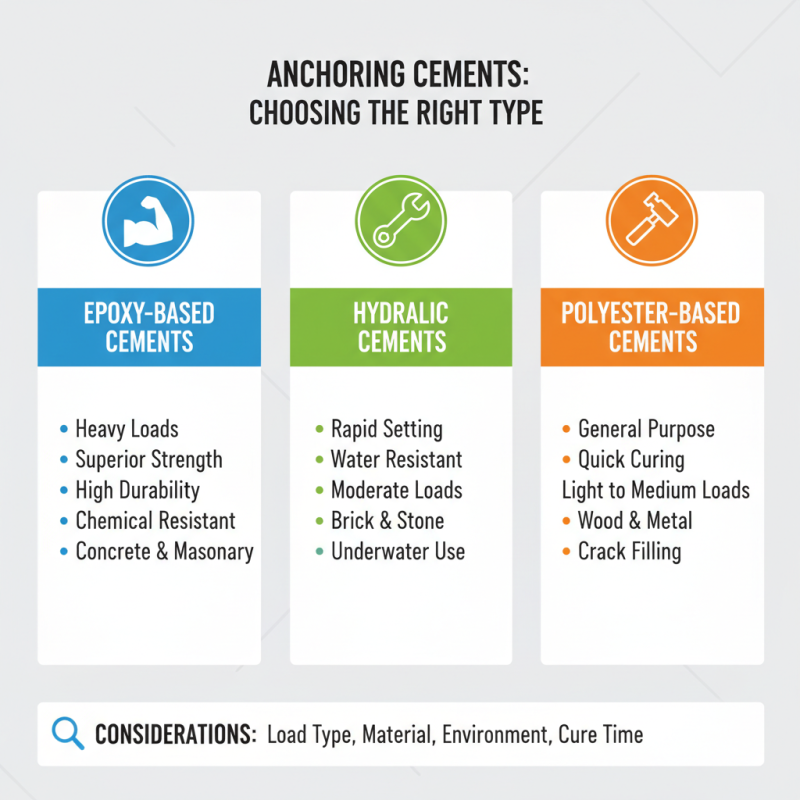

When starting a project that requires anchoring, understanding the types of anchoring cements is crucial. There are several varieties available, each suited to different conditions. For instance, epoxy-based cements are great for heavy-load applications because they offer superior strength and durability.

Tips: Always test the cement on a small section before full application. This ensures compatibility with the materials you're working with.

Polyester cements, on the other hand, are more versatile and dry quickly. They are ideal for both indoor and outdoor use. However, keep in mind that they may not be as strong as epoxy in certain scenarios. Consider the environment and load requirements thoroughly, as the wrong choice can compromise your project.

Tips: Check the temperature and humidity conditions. They can affect the curing process of the cement.

Another option is polyurethane-based cement. It provides excellent flexibility and can adapt well to movement in the substrates. Yet, it's essential to remember that these cements may not perform well in extreme temperatures. Balancing these factors is key to a successful outcome.

Choosing the right anchoring cement starts with understanding your project's specific requirements. Consider the material you will be anchoring into. Concrete, brick, and steel each have unique properties. The type of load, whether static or dynamic, also impacts your choice. Assess the environmental conditions too. Factors like humidity and temperature can influence cement performance.

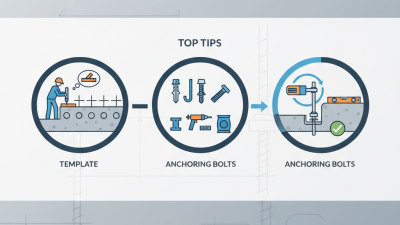

Tips: Assess the setting time needed for your project. Some cements cure quickly, while others offer more flexibility. Evaluate the ultimate strength required. Not all projects demand high-strength solutions. Seek advice from home improvement experts if you're unsure.

Avoid common mistakes like selecting the cheapest option without evaluating its suitability. Understand that sometimes a higher initial cost leads to better performance later. Mismatched materials can lead to project failure. Don't forget to consider the aesthetic aspect of your project. An effective anchoring solution should blend well with the overall design.

| Project Type | Environmental Conditions | Load Requirements | Cement Type Recommendation | Setting Time |

|---|---|---|---|---|

| Residential Construction | Indoor, Low Humidity | Moderate Load (up to 500 lbs) | Standard Quick-Set Cement | 20-30 minutes |

| Commercial Structures | Indoor/Outdoor, Variable | High Load (500-1000 lbs) | High-Strength Epoxy Cement | 60-90 minutes |

| Industrial Applications | Outdoor, Harsh Conditions | Very High Load (over 1000 lbs) | Heavy-Duty Anchoring Cement | 2 hours+ |

| Construction in Wet Conditions | Wet, Humid | Moderate to High Load | Water-Resistant Cement | 30-60 minutes |

Choosing the right anchoring cements is crucial for successful construction projects. Several key factors can significantly influence your decision. One important aspect is the load-bearing capacity. A recent industry report indicates that anchoring systems can bear loads ranging from 1,000 to over 20,000 pounds, depending on the type of cement used. Therefore, understanding your project’s specific load requirements is essential.

Another critical factor is the cure time. Fast-setting cements can be advantageous in time-sensitive situations, often curing within an hour. However, these may also compromise strength in high-stress environments. A detailed analysis of the project site can help determine if a longer cure time is beneficial or if speed is the priority. Environmental conditions must also be considered. Cements may behave differently under extreme temperatures or moisture levels, affecting overall performance.

Lastly, compatibility with base materials plays a vital role. Some cements bond better with concrete, while others are preferable for brick or masonry surfaces. A common mistake is assuming one type fits all. Testing various cements can lead to unforeseen problems later in the project. Understanding these factors not only ensures optimal performance but also prevents costly errors.

The above chart illustrates the key factors to consider when selecting anchoring cements for various projects. Each factor is rated on a scale from 1 to 10 based on its importance and performance. Understanding these aspects can help make informed decisions for the best results in your projects.

When selecting anchoring cements, performance and durability are crucial. Various studies indicate that epoxy-based cements provide superior bonding strength. In testing, some epoxies achieved tensile strengths exceeding 10,000 psi. This durability often translates to longer-lasting applications, particularly in heavy-load scenarios.

Conversely, some standard cements do not perform as well. For example, many cement formulations have tensile strengths around 3,000 to 5,000 psi. While these may be suitable for lighter tasks, they fall short in demanding environments. Inconsistent environmental factors, such as moisture and temperature changes, can further weaken these options over time.

Beyond strength, the curing time of anchoring cements varies significantly. Some formulations can set in less than an hour, ideal for quick projects. Others may take days to cure fully. This variability can impact project scheduling and efficiency. Evaluating the specific needs of each project and matching them with the right cement type is vital. Not every cement option will meet all project criteria. The balance between cost, longevity, and performance must be carefully managed.

Choosing the right anchoring cement is crucial for ensuring

strength and durability in your projects. When applying anchoring cements, surface preparation

is key. Clean the surfaces thoroughly to remove dust, grease, and any loose material. A clean substrate allows for better adhesion.

Tips: Always examine the environmental conditions before application.

Moisture can affect curing. If it rains, postpone your work.

Mix the anchoring cement according to the manufacturer’s instructions. An uneven mix can lead to weak bonds. Use a mixing paddle

for consistency. Pour the cement into the hole or form, ensuring it fills all corners. Avoid air pockets; they weaken the joint.

Tips: Work swiftly. Many cements have a limited working time. A delay

may lead to unpredictable results.

Curing is often overlooked but essential. Allow the cement to cure

fully per the guidelines. Rushing this step can compromise the bond. Observe the temperature and humidity, as these affect curing times.