Choosing the right anchoring cements for your projects is crucial. Poor choices can lead to structural failures and costly repairs. According to the "2023 Global Construction Materials Market Report," the demand for high-quality anchoring cements is on the rise, expected to grow by 8% annually. Industry expert Dr. Emily Tran emphasizes, "The right anchoring cement can make or break a project."

Many factors determine the best anchoring cements. Each project has unique requirements. For instance, environmental conditions and load-bearing capacities play significant roles. Improper selection may not only impact durability but also overall safety.

Considerations can be overwhelming. Not all products meet the rigorous standards expected in construction. Some manufacturers may exaggerate their claims, leading to confusion. Professional recommendations and independent testing can help clarify options. Yet, determining the best solution often requires careful analysis of specific project needs. The world of anchoring cements is complex, and the stakes can be high. Reflecting on these aspects is vital for successful project outcomes.

Choosing the right anchoring cement is crucial for your projects. Different types of anchoring cements serve various purposes. Epoxy-based cements provide strong bonding in most conditions. They work well for heavy loads. However, they can be more expensive and difficult to mix.

Polymer-modified cements offer versatility. They have good adhesion and can tolerate some movement. This makes them suitable for dynamic environments. Yet, their performance might decrease in extreme temperatures. It's important to check the manufacturer's guidelines.

Tips: Always consider environmental factors. Weather, temperature, and humidity can affect cement performance. Test the cement in small batches first. This helps you understand its setting time and workability. Remember, not all cements fit every job. Reflect on the specific needs of your project before making a choice.

| Type of Anchoring Cement | Application | Setting Time | Strength | Ideal Surface |

|---|---|---|---|---|

| Epoxy Cement | Heavy-Duty Applications | 30-60 Minutes | 3000-5000 psi | Concrete, Brick |

| Polyurethane Cement | Outdoor Applications | 15-45 Minutes | 2500-4000 psi | Masonry, Wood |

| Cementitious Grout | Structural Support | 1-3 Hours | 3000 psi | Concrete |

| Anchoring Mortar | General Purpose | 20-30 Minutes | 1500-3000 psi | Brick, Concrete |

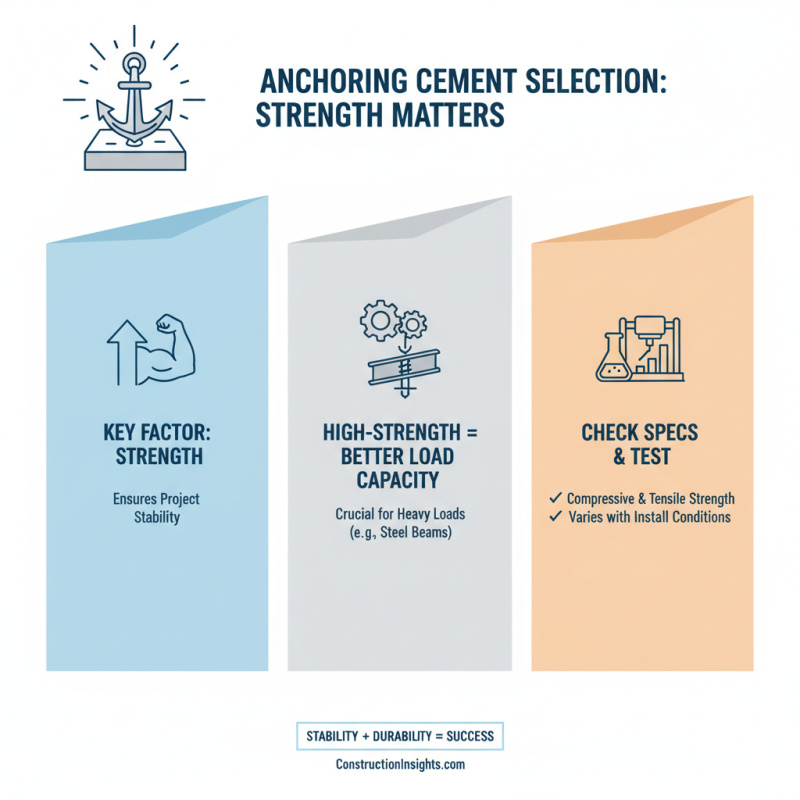

When selecting anchoring cements, strength is a pivotal factor. It directly affects the stability of your project. High-strength formulations offer better load-bearing capacity. This is critical for heavy-duty applications, like anchoring steel beams in construction. Test the compressive and tensile strengths mentioned in product specifications. But remember, these figures can vary based on installation conditions.

Durability is equally important to consider. Some cements may initially appear strong but degrade over time. Look for resistance to moisture, temperature fluctuations, and chemical exposure. Projects in harsh environments require materials that withstand such challenges. Always read reviews or feedback from past users to understand long-term performance. Sometimes, the final outcome depends on these subtle choices. We often overlook the importance of proper mixing and curing. Improper techniques can lead to unexpected failures. It’s vital to reflect on this aspect before starting your project.

When selecting anchoring cements, environmental factors are crucial. Current reports indicate that construction accounts for about 39% of global carbon emissions. Eco-friendly options, like low-VOC cements, are increasingly advocated. These cements help reduce air pollution and improve indoor air quality.

Water usage is another concern. Some analysts estimate that the production of traditional cements consumes around 1,500 liters of water for every ton produced. This can strain local water resources. Selecting alternatives with lower water requirements can mitigate this impact. It's vital to consider the water footprint of the materials used.

Waste management is often overlooked. In the U.S. alone, construction generates approximately 548 million tons of waste annually. Choosing cements that reduce packaging waste or can be recycled helps address this issue. These factors require serious thought to balance project needs and environmental responsibilities, promoting sustainability in construction.

Choosing the right anchoring cement is crucial for any construction project. Compatibility with project materials is a key factor often overlooked. For instance, a study by the American Society for Testing and Materials reveals that 30% of structural failures are due to improper material selection. This highlights the need for careful assessment.

Understanding the environmental conditions is equally important. Cement responds differently in wet versus dry climates. In a humid environment, a rapid-setting cement may weaken, while slow-curing options might be beneficial. Industry reports indicate that 25% of construction delays are linked to weather-related issues and unsuitable material choices. This data underscores the necessity of compatibility analysis.

Testing materials before making a decision is vital. Some projects may require unique mixes. However, many professionals neglect this step. They assume all cements are similar. This assumption can lead to costly mistakes. A study found that 15% of projects fail to pass inspections due to material incompatibilities. It's a reminder to prioritize assessment and testing for successful outcomes.

Choosing the right anchoring cement is crucial for the success of your project. Cost-effectiveness should always be a priority. Various types of anchoring cements are available. Each has a different price point. Finding the ideal balance between quality and cost can be challenging.

When budgeting for anchoring cements, consider the project scale. Larger projects might seem more daunting. However, bulk purchasing can often lead to savings. Keep track of your expenses closely. Use a spreadsheet for easy reference. Ensure to include delivery costs, too.

Some projects might lead you to prioritize price over quality. This can backfire, resulting in potential failures or safety issues. It’s essential to think long-term. Cheaper materials may save money initially but could lead to more expenses later. Always reflect on your choices. Comparing several options while keeping an eye on the budget will help you make better decisions for your projects.

This bar chart displays the cost per unit of anchoring cements across different projects, illustrating the cost-effectiveness of selecting appropriate materials for construction. Each project reflects different budgeting choices, impacting the overall expenditure related to anchoring cements.