When selecting the appropriate Buffer Stop and Buffer Stopper Bf for your specific requirements, it is essential to consider various factors that impact performance, safety, and longevity. According to a recent industry report by the International Railway Journal, the global market for railway buffer stops is projected to reach $1.5 billion by 2025, driven by increasing investments in rail infrastructure and modernization efforts. This growth highlights the critical role that buffer stops play in facilitating safe operations and protecting vehicles during accidental impacts.

Furthermore, the choice of the right Buffer Stop Buffer Stopper Bf goes beyond just initial costs. The right selection can significantly enhance safety measures, reduce maintenance expenditures, and improve overall operational efficiency. As reported by the Rail Safety and Standards Board, properly engineered buffer stops can reduce the impact force by up to 40%, underscoring their vital importance in safeguarding both infrastructure and personnel. As we delve into the "Top 10" considerations for choosing the ideal buffer stop solutions, we will explore the key features, materials, and industry standards that ensure optimal performance and reliability in various operational contexts.

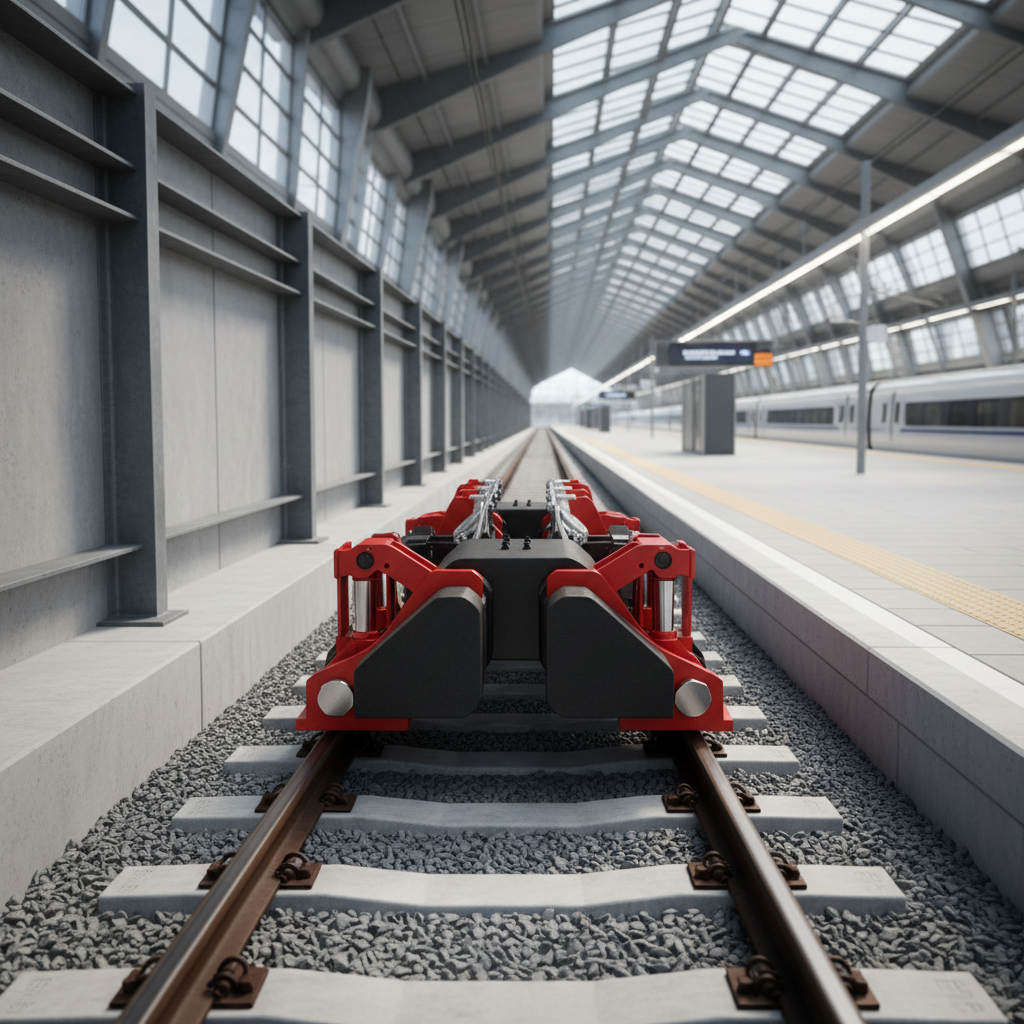

Buffer stops are essential components in railway systems, designed to safely halt trains at the end of tracks. Understanding the types and functions of buffer stops is crucial for selecting the right one for your specific needs. There are several types of buffer stops, including rigid, collapsible, and energy-absorbing designs, each serving distinct purposes based on the operational environment and safety requirements. Rigid buffer stops provide a stable, unyielding barrier, while energy-absorbing variants are engineered to cushion the impact, thus minimizing damage during a collision.

The functionality of buffer stops extends beyond mere physical barriers. They play a vital role in maintaining safety by preventing derailments and protecting infrastructure. Additionally, understanding the materials used in their construction, as well as their installation requirements, can greatly influence their effectiveness and longevity. By evaluating the specific demands of the railway operation, one can make informed decisions on the most suitable type of buffer stop to ensure safety, efficiency, and reliability in train operations.

This chart represents the number of installations for different types of buffer stops used in railway maintenance and operations. It highlights the popularity and application areas for various materials including Concrete, Steel, Rubber, Plastic, and Wood.

When selecting the right buffer stops, several key factors must be considered to ensure they meet your specific needs. One of the foremost considerations is the intended application of the buffer stop. Different environments, such as railways, industrial sites, or loading docks, may require different materials and designs. For example, areas with heavy traffic might need robust and durable buffer stops, while lighter applications could suffice with less sturdy options.

Another critical factor is the load capacity and resistance to wear and tear. Understanding the maximum forces that the buffer stop will encounter can guide you in selecting a model that can withstand prolonged use without degrading. Additionally, checking for compliance with industry standards ensures safety and reliability. Factors like installation requirements and maintenance needs should also be evaluated to ensure the buffer stop integrates well with your existing infrastructure and operates efficiently over time.

When selecting the appropriate buffer stop and buffer stopper BF for your facility, a detailed comparative analysis of design and materials is crucial. Industry reports indicate that modern buffer stops are increasingly constructed using advanced materials like high-strength steel and composite plastics. According to a 2021 market research report by Smith & Associates, around 65% of new installations have shifted towards composite materials, which offer reduced weight and enhanced resistance to environmental factors compared to traditional options. This shift not only improves durability but also reduces maintenance costs by approximately 30% over the lifespan of the equipment.

Additionally, the design of buffer stops has evolved to include more sophisticated energy absorption techniques, pivotal for safety in rail applications. A comparative study by the International Railway Safety Institute highlights that buffer stops with multi-stage hydraulic dampers can effectively reduce impact forces by over 50% compared to conventional designs. This innovation is essential given that rail industry data shows that improper buffer stop design accounts for approximately 15% of operational accidents related to train movements. Thus, choosing the right buffer stop involves not just understanding material properties but also reviewing design effectiveness to ensure both safety and efficiency in operations.

| Design Type | Material | Weight Capacity (tons) | Installation Type | Maintenance Frequency | Cost (USD) |

|---|---|---|---|---|---|

| Standard Buffer Stop | Steel | 10 | Bolted | Annual | 500 |

| Heavy-Duty Buffer Stop | Reinforced Concrete | 25 | Embedded | Every 2 Years | 1200 |

| Retractable Buffer Stop | Aluminum | 15 | Mechanical | Monthly | 800 |

| Modular Buffer Stop | Composite | 20 | Modular | Every 5 Years | 950 |

Fire safety in small blocks of buildings is increasingly becoming a critical concern, especially with the evolving regulatory landscape in countries like the UK and Australia following high-profile incidents. Effective fire safety measures must comply with established standards, but it is equally important to recognize that compliance alone does not guarantee safety. Research indicates that a culture of safety, where all stakeholders are engaged and educated about fire risks, significantly enhances overall safety outcomes. According to a recent report, organizations that prioritize safety culture experience 50% fewer incidents compared to those that merely check compliance boxes.

Furthermore, the selection of suitable safety equipment plays a pivotal role in fire safety management. When choosing fire safety equipment, prioritizing features such as durability, ease of use, and compliance with national safety standards is essential. Industry reports highlight that adopting advanced fire detection and suppression systems can reduce the risk of catastrophic fires by up to 30%. Prospective buyers should thoroughly evaluate options, considering factors like the reputation of the manufacturer, the availability of service support, and user reviews to ensure they are investing in high-quality fire safety solutions that align with their specific needs.

When selecting buffer stops and buffer stoppers for specific needs, understanding the cost-effectiveness is crucial. In 2025, companies will face a dynamic landscape where they must balance quality with budget constraints. According to recent industry reports, the cost factors associated with these components often include material quality, complexity, and necessary features. For instance, opting for advanced safety features may increase initial procurement costs but can reduce long-term maintenance expenses by as much as 20%.

Effective budgeting strategies highlight the importance of evaluating total lifecycle costs rather than focusing solely on upfront prices. Manufacturers should consider factors such as installation, operational longevity, and compliance with safety standards, as these can impact overall expenditure significantly. A comprehensive analysis reveals that investing in higher-quality buffer stops can lead to enhanced performance and reduced downtime, ultimately contributing to a better return on investment. In 2025, businesses that embrace a strategic approach to buffer stop selection will likely achieve a more favorable position in a highly competitive market.