When it comes to the construction and maintenance of railways, one component stands out as being crucial to the stability and safety of the entire system: the railroad bolt. These seemingly simple fasteners play a significant role in securing the rails, ties, and other infrastructure components, ensuring that trains can operate smoothly and safely. Understanding the essential facts about railroad bolts not only benefits industry professionals but also enhances the knowledge of anyone interested in railway systems.

In this article, we will explore the top ten essential facts about railroad bolts that you need to know. From material specifications to installation techniques, each aspect sheds light on why these fasteners are vital in railway applications. The durability, strength, and design of railroad bolts are paramount in withstanding the rigorous demands of train travel, including heavy loads and dynamic forces. Join us as we delve into the characteristics that make railroad bolts an indispensable element of railway construction and maintenance.

Railroad bolts are specialized fasteners designed to secure rails to railroad ties, ensuring the stability and safety of train tracks. These bolts play a crucial role in track construction, as they must withstand significant forces from trains, weather, and natural ground shifts. Their design typically includes a unique head shape, often resembling a square or hexagon, which prevents them from loosening during operation. The materials used for railroad bolts are chosen for durability and resistance to corrosion, which is essential given the exposure to the elements over time.

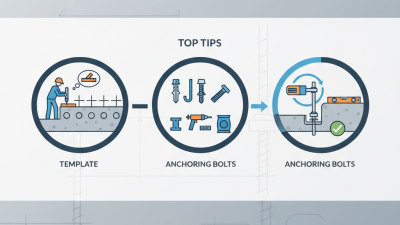

When working with railroad bolts, here are some tips to ensure optimal performance and safety. First, always select the appropriate size and grade of bolt for the specific application to prevent inadequate load-bearing capacity. Secondly, regular inspection is key; check for signs of wear or loosening to address any potential issues before they escalate. Lastly, proper installation techniques must be followed, utilizing the correct torque specifications to ensure that the bolts are securely fastened, maintaining the integrity of the track structure.

Understanding the importance of railroad bolts is essential for anyone involved in track construction or maintenance. Their reliable performance is paramount to the safety and efficiency of rail transport, making it critical to adhere to best practices in selection, inspection, and installation.

Railroad bolts are essential components in the infrastructure of railways, ensuring the integrity and stability of tracks. Among the various types of railroad bolts, there are four primary categories: standard bolts, lag bolts, anchor bolts, and tie bolts. Each type serves specific applications vital to the safety and efficiency of rail transport. For instance, standard bolts are commonly used in the assembly of track joints, where their ability to withstand significant tensile loads is critical. According to a report by the American Railway Engineering and Maintenance-of-Way Association (AREMA), the use of high-strength bolts can enhance the lifespan of rail joints by up to 30%.

Lag bolts, on the other hand, are often used to secure railway ties to the track structure. Their design allows for better grip and resistance against vibrations, which is particularly important in high-speed rail scenarios. The International Union of Railways (UIC) indicates that properly installed lag bolts can reduce maintenance intervals by approximately 15%, thus lowering operational costs. Anchor bolts are crucial in attaching rails to concrete sleepers, providing the necessary stability to withstand dynamic loads from moving trains. Lastly, tie bolts play a vital role in holding rail ties together, ensuring they remain firmly in place under the stress of heavy freight and passenger trains. Understanding the specific applications of each type of railroad bolt is crucial for engineers and maintenance teams to optimize track performance and safety.

| Type of Railroad Bolt | Material | Diameter (mm) | Length (mm) | Application |

|---|---|---|---|---|

| Standard Railroad Bolt | Steel | 16 | 100 | Track fastening |

| Fish Bolt | Carbon Steel | 12 | 150 | Joint assembly |

| Lag Bolt | Stainless Steel | 16 | 200 | Securing ties |

| Tensile Bolt | High-Strength Steel | 20 | 120 | Heavy-duty fastening |

| Shouldered Bolt | Alloy Steel | 14 | 75 | Track alignment |

| Hex Bolt | Galvanized Steel | 18 | 90 | General fastening |

| Elevated Bolt | Steel | 15 | 110 | Support for elevated tracks |

| Bridge Bolt | High-Strength Steel | 22 | 160 | Bridge connections |

| Clipped Bolt | Carbon Steel | 10 | 85 | Track assembly |

| Split Bolt | Stainless Steel | 16 | 100 | Chain link fastening |

Railroad bolts are critical components in the construction and maintenance of railway systems, ensuring the stability and safety of tracks. The manufacturing of these bolts typically involves several key materials, each chosen for their unique properties and ability to withstand the harsh conditions encountered in rail operations. Steel is the most common material used due to its strength and resilience. Different grades of steel can be employed, with higher grades offering enhanced tensile strength and resistance to deformation, which are vital in preventing track dislodgement.

In addition to steel, other materials such as alloy combinations are often utilized to optimize performance. For example, adding materials like nickel or chromium can enhance the corrosion resistance of railroad bolts, making them suitable for areas with extreme weather conditions or exposure to moisture. Furthermore, the fasteners may undergo processes like galvanization to provide an additional barrier against rust and oxidation. By carefully selecting and treating these materials, manufacturers can produce railroad bolts that not only meet the rigorous demands of rail systems but also contribute to their longevity and reliability.

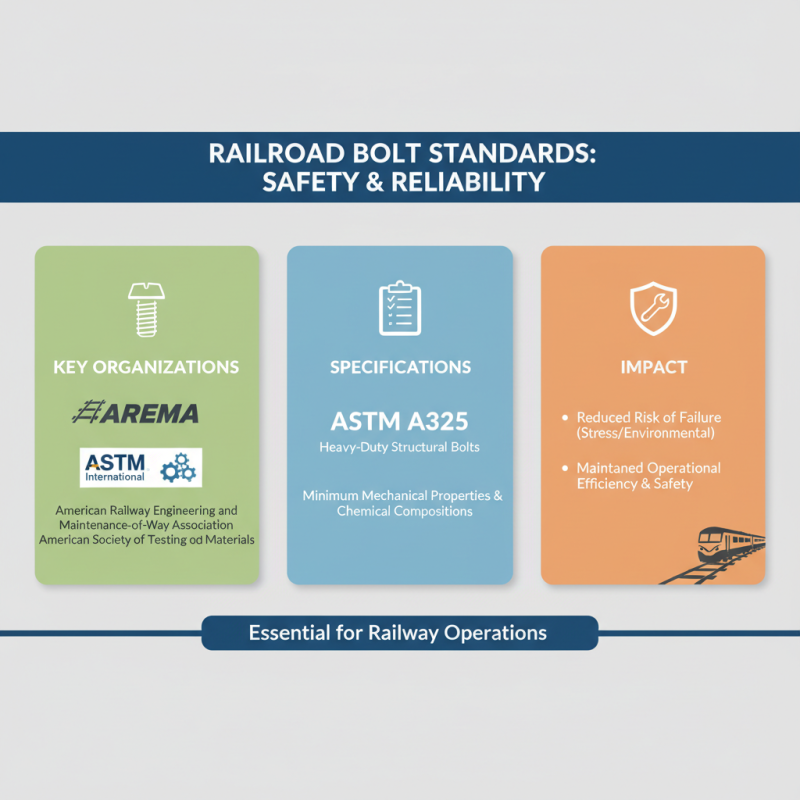

When discussing railroad bolts, understanding the standard specifications and regulations governing these critical components is essential for ensuring safety and reliability in railway operations. Railroad bolts must meet stringent requirements set forth by organizations like the American Railway Engineering and Maintenance-of-Way Association (AREMA) and the American Society for Testing and Materials (ASTM). For instance, ASTM A325 specification outlines the minimum mechanical properties and chemical compositions required for heavy-duty structural bolts used in railway infrastructure. Research indicates that adherence to these standards can significantly reduce the risk of failure due to stress or environmental factors, which is crucial for maintaining operational efficiency and safety.

Moreover, the materials used in the manufacturing of railroad bolts play a vital role in their performance. Typically, high-strength carbon steel is used, which undergoes various treatments to enhance durability and resistance to corrosion. According to a report from the National Transportation Safety Board (NTSB), approximately 28% of rail-related accidents can be attributed to structural failures, highlighting the importance of using standardized bolts that comply with established specifications. Additionally, regular inspections and maintenance as per the Federal Railroad Administration (FRA) guidelines are crucial, as consistent wear and tear can compromise the integrity of the fastening system over time. Understanding these regulations and specifications not only helps in selecting the right components but is essential for the overall safety of railway systems.

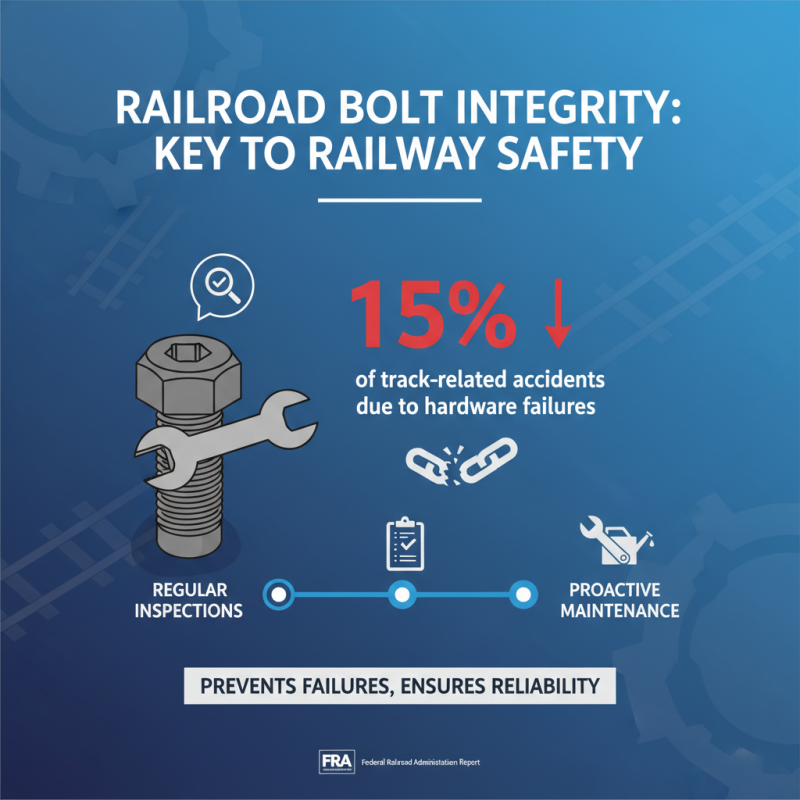

Maintaining the integrity of railroad bolts is crucial for ensuring the safety and reliability of railway operations. Regular inspections and maintenance practices play a vital role in preventing failures that could lead to accidents. According to a report by the Federal Railroad Administration, approximately 15% of track-related accidents are attributed to hardware failures, including those of railroad bolts. This highlights the need for consistent monitoring and proactive maintenance strategies.

Common maintenance practices include routine inspections, torque verification, and replacement of worn or damaged bolts. Inspections should occur at regular intervals, evaluating the condition of the bolts for signs of wear, corrosion, or loosening. A study by the American Railway Engineering and Maintenance-of-Way Association indicates that proper torque application and periodic checks can extend bolt life by up to 30%. Additionally, employing protective coatings can mitigate the risk of corrosion, which is a leading cause of bolt degradation in harsh environmental conditions.

Furthermore, keeping an up-to-date maintenance log is essential for tracking the performance of bolts over time. This practice aids in predictive maintenance, allowing railway operators to identify patterns and address potential issues before they escalate. Ultimately, by implementing these common maintenance practices, the integrity of railroad bolts can be preserved, ensuring safer and more efficient rail transport systems.