When embarking on a project that involves the use of railroad rail, making informed decisions is crucial to ensure safety, efficiency, and durability. The choice of the right railroad rail can significantly impact the overall performance of your rail infrastructure, whether it's for a new construction project or an existing system needing upgrades. With countless options available, understanding the various types, specifications, and material qualities of railroad rails is essential in order to meet the specific demands of your project.

Selecting appropriate railroad rail requires careful consideration of multiple factors, such as load capacity, rail weight, and the environmental conditions the rail will be subjected to. Additionally, the intended use of the rail—whether for freight, passenger transport, or industrial purposes—will dictate different requirements. Therefore, it is imperative to grasp the fundamental characteristics of railroad rails, as this knowledge will guide you in making choices that enhance both functionality and longevity while adhering to industry standards.

In this article, we will explore essential tips and considerations that will empower you to choose the right railroad rail for your project, ultimately leading to a successful and sustainable rail system. By the end, you will be equipped with the insights needed to navigate the complexities of railroad rail selection and ensure the optimal performance of your rail infrastructure.

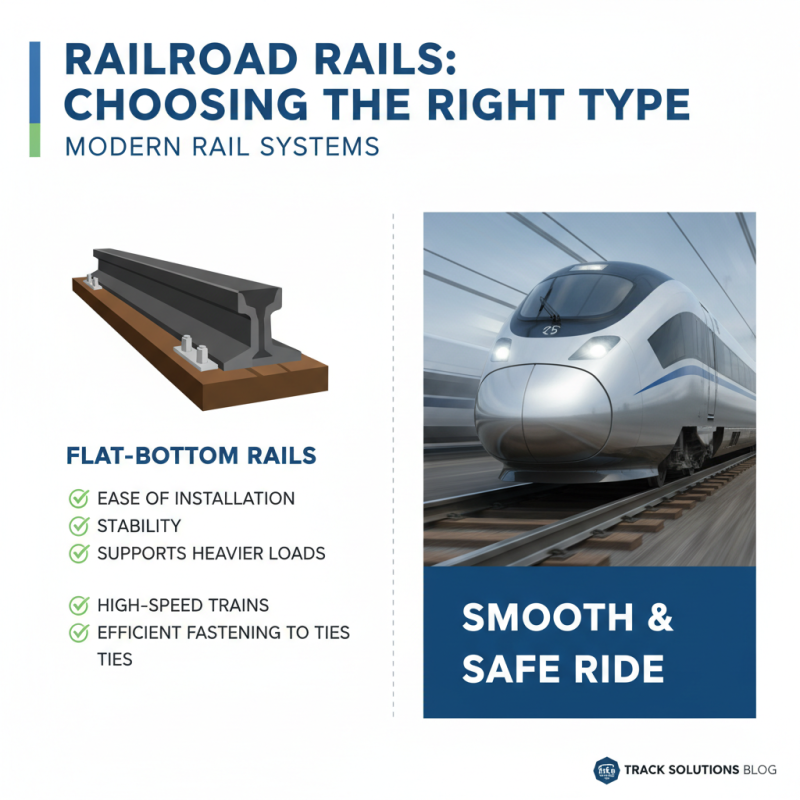

When choosing the right railroad rail for your project, it’s crucial to understand the different types of rails available and their specific applications. The primary types of railroad rails include flat-bottom rails, which are prominently used in modern rail systems due to their ease of installation and stability. They are designed to support heavier loads and are suitable for high-speed trains, providing a smooth and safe ride. Their flat base allows for efficient fastening to the ties, ensuring a firm grip on the track structure.

Another common type is the bullhead rail, characterized by its symmetrical profile. Traditional in many legacy rail systems, bullhead rails are ideal for environments where track maintenance is frequent, as they can be easily re-laid. They are often used in tram and light rail systems. Additionally, there are grooved rails specifically designed for streetcars and light railways, allowing vehicles to navigate urban environments where space is limited. Understanding these rail types, their configurations, and intended uses is vital for selecting the appropriate rail for your project's specific demands, ensuring safety, reliability, and efficiency in rail transport.

When selecting the right railroad rails for your project, several critical factors must be taken into account to ensure safety, durability, and cost-effectiveness. One of the primary considerations is the type of rail material. Commonly used materials include steel and concrete, each offering distinct advantages for different applications. Steel rails, known for their high strength and flexibility, are widely preferred for heavy freight operations, while concrete rails can provide increased stability in certain environments, particularly in urban settings or inclined grades.

Another important aspect to consider is the rail profile and weight. The weight of the rail directly affects its load-bearing capacity and overall performance under traffic. Heavier rails tend to have better wear resistance and can accommodate higher loads, making them ideal for high-traffic areas. Additionally, the chosen rail profile should align with the specific requirements of the railbed and the expected load dynamics. Finally, the environmental conditions at the installation site—such as climate, soil type, and potential exposure to corrosive elements—should also guide your selection process, ensuring that the chosen rails will withstand local conditions over their lifespan.

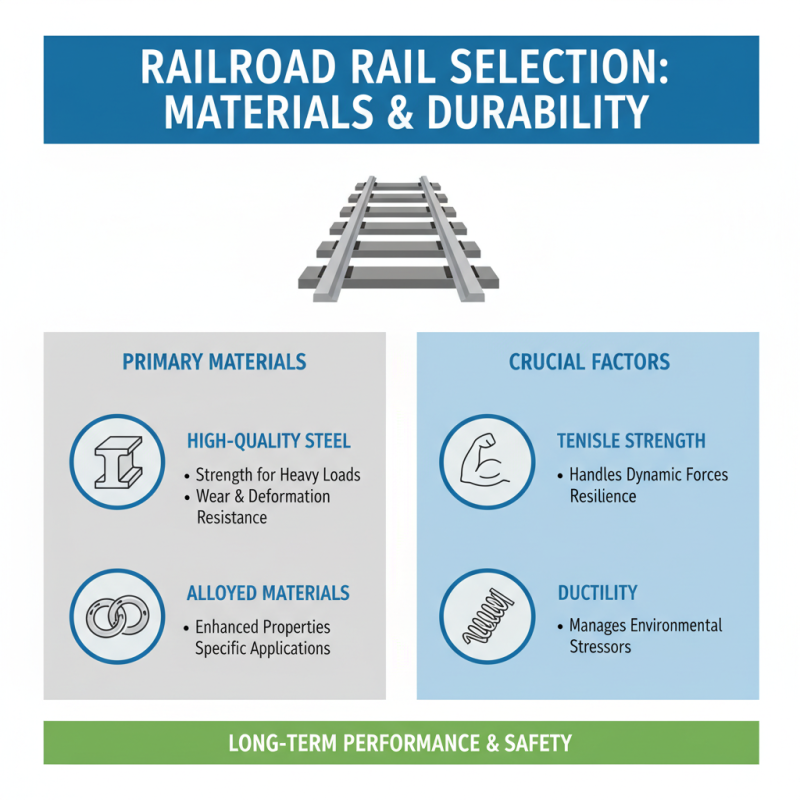

When selecting railroad rails for your project, assessing material quality and durability is crucial for long-term performance and safety. The primary materials used in railroad rail production are steel and alloyed materials, each offering distinct advantages. High-quality steel not only provides the necessary strength to withstand heavy loads but also ensures resilience against wear and deformation over time. Additionally, consider factors like tensile strength and ductility, as these properties significantly influence the rail's ability to handle dynamic forces and environmental stressors.

Durability is another essential aspect to evaluate when choosing railroad rails. A rail's resistance to corrosion and fatigue plays a significant role in its lifespan. Factors such as the environment in which the rails will be placed—whether in coastal areas with high salt exposure or regions with extreme temperature fluctuations—must be considered. Utilizing advanced treatment processes, like heat treatment or protective coatings, can enhance the durability of the rails, making them less prone to damage and reducing maintenance needs. Prioritizing quality and durability in your choice of railroad rails will ensure a reliable infrastructure that meets the demands of your project while minimizing long-term costs.

When selecting railroad rails for your project, understanding cost and budget constraints is crucial. The first step in evaluating costs involves analyzing the specific requirements of your project, such as the type of rail needed based on traffic loads and environmental conditions. Costs can vary significantly depending on the length, weight, and quality of the rail material chosen. It’s essential to gather quotes from multiple suppliers to gain a comprehensive picture of price ranges and identify potential bulk purchasing discounts that can help stay within budget.

Another consideration is the lifecycle cost of the rails. While it might be tempting to choose the cheapest option, investing in higher-quality rails can lead to long-term savings due to reduced maintenance needs and longer durability. It’s important to factor in these potential costs when making your selection, as well as logistical expenses such as transportation and installation. A thorough cost-benefit analysis will help ensure that you select the right railroad rail that meets your project’s financial limitations while also meeting operational needs. Balancing initial expenses with long-term value is vital for making an informed decision.

| Rail Type | Cost per Ton ($) | Typical Application | Weight per Meter (kg) | Estimated Lifespan (Years) |

|---|---|---|---|---|

| Heavy Structural Rail | 800 | Freight Transportation | 60 | 30 |

| Light Rail | 600 | Urban Transit | 40 | 20 |

| CWR (Continuous Welded Rail) | 850 | High-Speed Rail | 55 | 25 |

| Steel Rail | 700 | Conventional Rail | 50 | 20 |

When selecting railroad rails for your project, one of the most critical aspects to consider is compliance with industry standards and regulations. Each country and region may have specific safety and quality requirements that must be met to ensure the rail's suitability for its intended application. Understanding organizations that set these standards, such as the American Railway Engineering and Maintenance-of-Way Association (AREMA) or equivalent bodies in other regions, can provide a foundation for making informed decisions.

In addition to familiarizing yourself with standards, it’s essential to assess your project's specific requirements against these regulations. Consider factors like the expected weight loads, environmental conditions, and the types of rolling stock that will utilize the rail. By doing so, you will not only ensure safety and reliability but also reduce the risk of costly delays and modifications in the future. Continuous monitoring of regulatory updates is also vital, as standards evolve in response to new technologies and safety concerns. Emphasizing compliance at the outset will facilitate a smoother process and guarantee that your railroad project meets both safety and performance expectations.