In recent years, the demand for innovative fastening solutions has surged within various industries, driving the adoption of advanced technologies like Boltable Clips. A 2022 market analysis by Research and Markets indicated that the global fastening market is expected to reach $98 billion by 2025, with boltable fastening systems playing a significant role in this growth. This surge can be attributed to their versatility and reliability, essential qualities in construction, automotive, and manufacturing sectors.

Boltable Clips stand out for their ability to simplify assembly processes while ensuring structural integrity. According to the Fastener Industry Collaborators (FIC), efficient fastening solutions can enhance productivity by up to 30%, significantly impacting project timelines and costs. Moreover, their design accommodates a variety of materials, making them a preferred choice among engineers and builders. As we explore the top 10 essential tips for incorporating Boltable Clips into your projects, understanding their advantages and applications will equip you with the knowledge to optimize project outcomes effectively.

When embarking on a project that requires the use of boltable clips, selecting the right type is crucial for ensuring structural integrity and ease of assembly. According to a report by the Fastener Industry Association (FIA), over 30% of project delays can be attributed to the misselection of fasteners and accessories, underlining the importance of making informed choices.

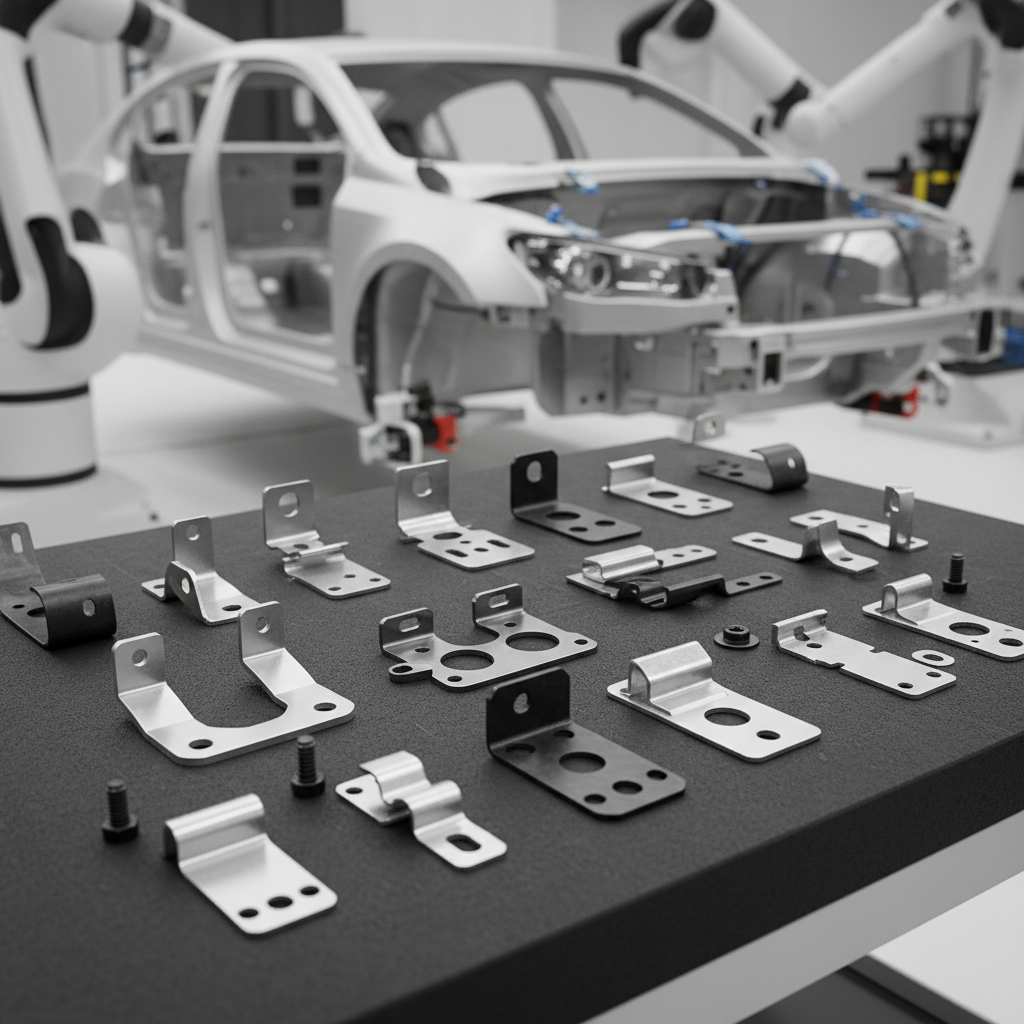

Boltable clips come in various designs, including standard clips, locking clips, and adjustable clips, each suited for different applications in both industrial and DIY settings.

For instance, standard boltable clips are ideal for static applications where minimal movement occurs, while locking clips provide enhanced security for applications subject to vibration or dynamic loads. A study by the Engineering Society found that projects using the appropriate clip type experienced 25% less wear and failure compared to those that did not account for this factor. Additionally, adjustable clips offer versatility, allowing for alignment adjustments during installation, which can be particularly beneficial in complex assemblies. Understanding these nuances can significantly impact project outcomes and efficiency.

When it comes to installing boltable clips, adhering to best practices is crucial for achieving optimal performance and ensuring durability in your projects. According to a recent industry report by the International Fastener Association, nearly 40% of mechanical failures in constructions can be traced back to improper installation of fastening systems, including clips. Therefore, understanding the nuances of boltable clip installation is essential.

One key tip is to always pre-drill holes to the appropriate size before installing the clips. This helps to minimize material stress and ensures a tighter fit, which can significantly enhance the clip’s hold. Additionally, using a torque wrench to tighten the bolts to the manufacturer’s specifications can prevent over-tightening, which is a common issue that leads to striping or damaging the material. In fact, research shows that projects that implemented torque specifications reported a 30% reduction in fastener failure rates.

Another important practice is to consider environmental factors, as clips made from materials not suited for specific environments can lead to corrosion and failure. A thorough evaluation of materials, such as choosing stainless steel clips for outdoor applications, can extend the life of your installation and improve overall reliability. Remember, investing time in proper installation techniques not only enhances the longevity of your projects but also ensures safety and efficiency.

When working with boltable clips, having the right tools and materials is crucial for ensuring successful installation and long-lasting results. First, an assortment of boltable clips in different sizes is essential to accommodate various project requirements. These clips not only secure components together but also allow for easy disassembly and adjustments, making them a versatile choice for both temporary and permanent applications.

In addition to clips, a reliable set of hand tools is necessary. A quality wrench or socket set will facilitate the tightening and loosening of bolts, ensuring that your clips are secured properly. Furthermore, having a cutting tool, such as a utility knife or wire cutter, can help you tailor components to fit snugly with the clips. Don’t forget about protective equipment, such as gloves and safety glasses, to safeguard against any potential injuries while working on your projects. Together, these essential tools and materials will equip you for effective and safe use of boltable clips in your work.

When using boltable clips in your projects, avoiding common mistakes can significantly enhance your efficiency and the quality of your work. One frequent error is neglecting to choose the right size and type of clip for your specific application. Using clips that are too small or too large can lead to improper fastening, resulting in weak connections or potential material damage. Always ensure that the selected clips are compatible with the materials and the load they will bear.

Another common pitfall is improper installation. Failing to secure the clips adequately can compromise the strength of the assembly. It's essential to follow the manufacturer's guidelines for torque specifications and installation techniques. Additionally, overlooking pre-installation checks—such as ensuring the surfaces are clean and free from debris—can lead to ineffective bonding. By paying attention to these details, you can prevent costly mistakes and ensure a successful outcome in your projects.

Boltable clips have emerged as a versatile solution across various industries, revolutionizing how components are assembled and secured. Notably, these clips find significant applications in the automotive sector. According to a report by the Global Automotive Clips Market, the demand for fastening solutions, including boltable clips, is projected to grow by 5% annually through 2025. This demand stems from the increasing need for lightweight and robust assembly methods in vehicle production, enabling manufacturers to enhance safety and efficiency while reducing overall costs.

In the construction industry, boltable clips are essential for streamlining the assembly of frameworks and supports. They provide a reliable way to secure connections between heavy materials, ensuring structural integrity. The Construction Equipment Market Analysis highlights that the integration of innovative fastening solutions like boltable clips can reduce installation time by up to 30%, significantly improving project timelines and labor costs.

When utilizing boltable clips in your projects, one key tip is to always select the right material for the clips based on the specific environmental conditions—such as exposure to moisture, temperature fluctuations, and corrosion potentials. Another important consideration is ensuring that the clips are properly sized and torqued to avoid any potential loosening over time, especially in applications that undergo regular movement or vibration.