In the realm of construction, the effective installation of anchoring bolts in concrete foundations is crucial. According to Dr. Emily Harrison, a leading expert in structural engineering, “Properly installed anchoring bolts are vital for the integrity of any concrete structure.” This highlights the significance of getting the installation process right.

When working with anchoring bolts in concrete foundations, many people overlook critical details. The alignment and depth of these bolts can determine their effectiveness. It's not just about drilling and setting; attention to material compatibility and environmental factors is essential. Many construction projects have faltered due to improperly installed bolts, leading to increased costs and unsafe structures.

Understanding the nuances of this installation method can be daunting. Contractors often rush the process. They may underestimate the preparation needed. This can lead to serious problems down the line. A careful, methodical approach will ensure better performance and safety. Each step taken in installing anchoring bolts in concrete foundations aids in creating a robust structure. Investing time in this phase is a step towards long-lasting construction.

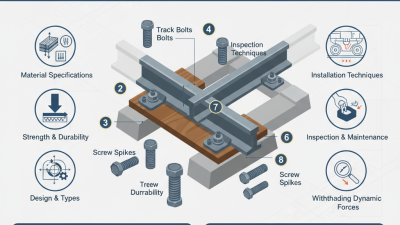

Anchoring bolts play a crucial role in construction. They secure structures to concrete foundations. These bolts can be used in a variety of applications.

From supporting heavy machinery to stabilizing buildings, their strength is essential. Understanding their types is important for successful installations.

When planning to install anchoring bolts, consider the concrete's properties. Ensure the mix is suitable for your project’s demands. Use proper measuring tools to mark correct bolt locations.

Accuracy in placement impacts the overall strength of the installation.

Tips: Always double-check measurements before drilling. Small errors can lead to major problems. Pre-drill holes to avoid cracking the concrete.

A clean work area is vital for safety and efficiency. Don't rush the process; each step is important. Consider consulting with a professional if unsure.

Preparing the concrete foundation is crucial for installing anchoring bolts efficiently. Before you start, ensure that the surface of the concrete is clean and free of dust or debris. Use a broom or a compressed air tool to achieve this. Uneven surfaces may lead to improper bolt placement. Inspect for any cracks or weaknesses that need repair. If the surface isn't level, consider using a concrete grinder.

Next, mark the locations where the bolts will be installed. Precision is key. Use a measuring tape and chalk line for accuracy. Some might overlook this step, leading to misaligned bolts. Once marked, drill holes to the recommended depth. Ensure you have the right bit size according to the bolt specifications. This step can be tricky; check your measurements twice. A wrong hole size can result in insufficient holding strength later on. Don't rush; take your time to ensure each step is done correctly.

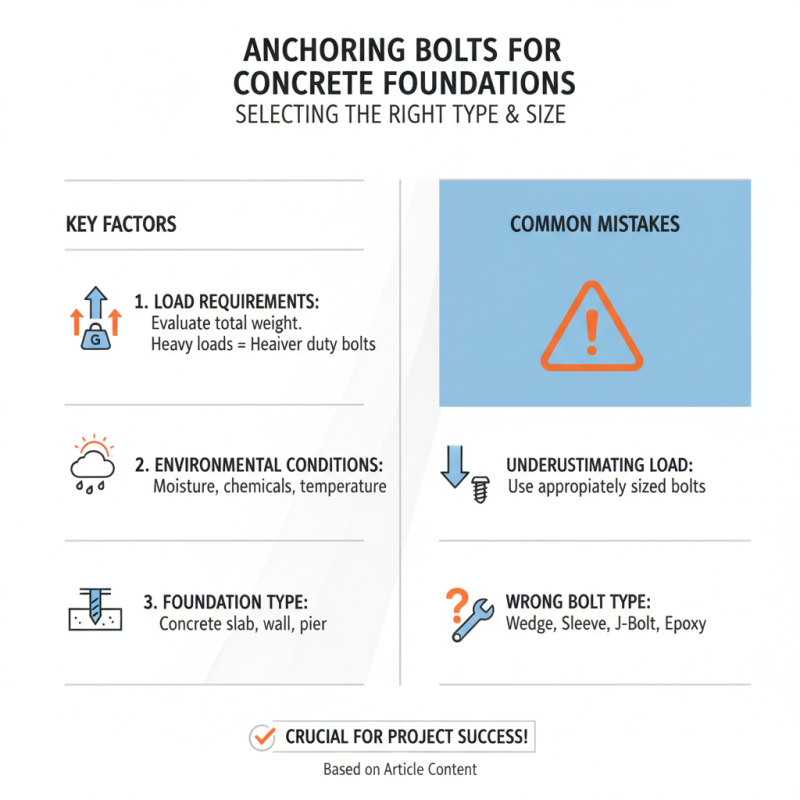

Selecting the right type and size of anchoring bolts is crucial for any concrete foundation project. The choice depends on various factors, including load requirements and environmental conditions. For heavy loads, heavier-duty bolts are often necessary. A common mistake is underestimating the load. Be sure to evaluate weight and use appropriately sized bolts.

Dimensions also matter. Standard lengths typically range from 3 to 12 inches. However, a short bolt may not provide enough grip, while a long one could cause complications during installation. Always consult the specifications of your project. Unintended outcomes can arise from incorrect sizes or types. This can lead to safety issues later on.

Take the time to think about material compatibility. Galvanized or stainless-steel bolts are often used for outdoor projects. Certain environments may be corrosive, demanding stronger materials. Ignoring these details can have serious repercussions for the foundation. Be diligent in your selection, and it might save you from future headaches.

Installing anchoring bolts in concrete requires careful planning and execution. Begin by marking the locations for the bolts on the concrete surface. Use a chalk line to ensure accuracy. A mistake here can lead to misalignment, complicating the installation.

Next, drill holes into the concrete. Choose a drill bit that matches the size of the anchor bolts. It's important to drill straight. Use a hammer drill for efficiency. Monitor your depth, as too shallow holes can lead to weak support. Once the holes are made, clean any debris using a brush or air compressor.

Insert the anchoring bolts into the holes. Ensure they are secure and at the correct level. If necessary, adjust their position. Sometimes they might not align perfectly, which can be frustrating. After placement, fill the holes with anchor adhesive or concrete for added support. Let it cure as per the manufacturer's instructions. This step is crucial for strength. Skipping it can lead to failure later. Stay vigilant and check your work throughout the process to avoid costly mistakes.

| Step | Description | Materials Required | Estimated Time |

|---|---|---|---|

| 1 | Prepare the concrete surface by cleaning and removing debris. | Broom, Vacuum | 15 minutes |

| 2 | Mark the locations where the anchoring bolts will be installed. | Measuring Tape, Marker | 10 minutes |

| 3 | Drill holes into the concrete using a hammer drill to the required depth. | Hammer Drill, Drill Bit | 30 minutes |

| 4 | Insert the anchoring bolts into the drilled holes and ensure they are level. | Anchoring Bolts, Level | 20 minutes |

| 5 | Pour epoxy or concrete adhesive into the holes around the bolts. | Epoxy, Mixing Tool | 15 minutes |

| 6 | Allow the adhesive to cure as per the manufacturer's instructions. | None | Varies |

| 7 | Inspect the installation to ensure stability and security. | Visual Inspection | 10 minutes |

When installing anchoring bolts in concrete foundations, ensuring stability and safety is critical. Data from the American Concrete Institute reveals that improperly installed anchors can lead to structural failures. These failures are often irreversible and costly. Therefore, paying close attention to installation practices is essential.

Precision during the drilling process can make a significant difference. The recommended drill bit diameter should align closely with the bolt size. Oversized holes can reduce pull-out strength, weakening the entire structure. A report by the International Journal of Engineering Studies suggests that even a small deviation can decrease load capacity by up to 30%. Consider using a torque wrench for accurate tightening. Improper torque can result in inadequate anchoring.

Environmental factors also play a role in the longevity of anchoring systems. Corrosive conditions can compromise bolt integrity over time. It’s beneficial to choose appropriate materials and coatings based on the environment. Always check for standards and guidelines to avoid misunderstandings. A study from the National Association of Corrosion Engineers emphasizes the need for regular inspections to sustain structural safety. Reflecting on these practices may reveal areas needing improvement. Prioritizing proper methods can ultimately save time and resources.