A Switch Stand is a crucial component in railway systems. It provides a mechanism for directing trains onto different tracks. Understanding how a Switch Stand operates is essential for railway safety.

In railway yards or junctions, the Switch Stand controls track alignment. Operators use it to direct trains efficiently. Each stand includes a visible arm to indicate the track's position. This visual cue is vital for train conductors and engineers. However, not all Switch Stands operate flawlessly. Weather conditions can affect their performance. Even minor malfunctions could lead to delays or accidents.

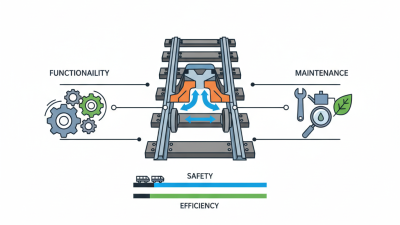

Routine maintenance is necessary for optimal function. Ignoring these tasks can cause friction between tracks. Operators may face challenges in ensuring reliable service. It's crucial to balance efficiency with safety. Every Switch Stand has its quirks. Understanding these traits is part of the job. The evolution of Switch Stands shows progress, but room for improvement remains.

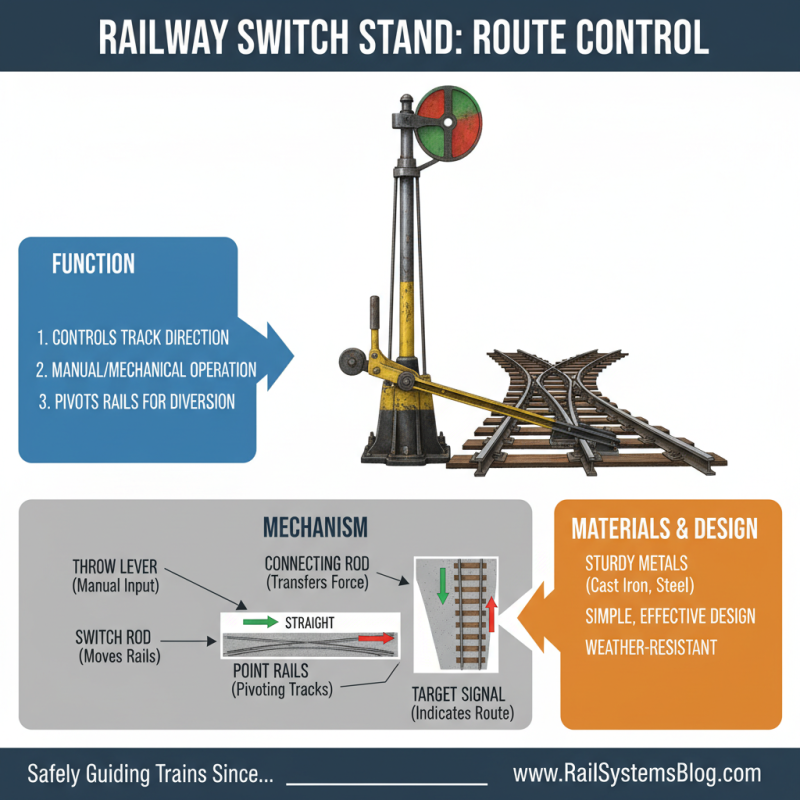

A switch stand is a mechanical device used in rail systems. It allows trains to choose between different tracks. This is crucial for managing rail traffic efficiently. The switch stand is often positioned at rail junctions. Operators can manually adjust the track direction using a lever.

The design of a switch stand can vary. Generally, these stands feature a long handle attached to a rotating mechanism. When the handle moves, it changes the position of the track's points. This movement requires strength, especially in older systems. Sometimes, operators struggle with heavy levers, making it a challenge.

These devices are visible from a distance. Bright colors usually indicate a track's status. However, visibility can sometimes be poor at night or in bad weather. Operators must remain vigilant. Miscommunication or mistakes can lead to serious issues. It’s essential to ensure that all parts function correctly before trains pass.

| Dimension | Description | Function | Material | Maintenance Frequency |

|---|---|---|---|---|

| Height | Typically ranges from 1.5 to 3 feet | Allows for manual or mechanical operation of switches | Steel or Aluminum | Monthly |

| Width | Varies; often around 1 foot | Regulates track switching for locomotives | Cast Iron or Composite Material | Quarterly |

| Weight | Ranges from 50 to 300 pounds | Facilitates switch direction for trains | Galvanized Steel | Yearly |

| Length | Around 2 to 5 feet | Provides visual indication of switch position | Plastic or Reinforced Polymer | Annually |

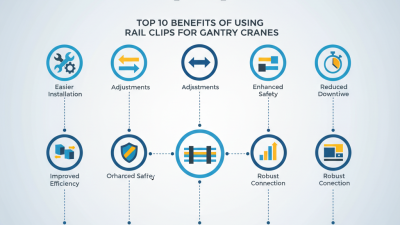

A switch stand is a crucial component in rail systems, directing trains to different tracks. Understanding its basic components helps appreciate its function. Switch stands typically include the lever, connecting rods, and the switch plates.

The lever is often the most visible part. Operators use it to change the position of the track switches. It may seem simple, yet handling it requires skill. Nearby, the connecting rods link the lever to the switch plates. If these rods are misaligned or damaged, issues arise. Trains may not switch tracks correctly, leading to dangerous situations.

Switch plates are the parts that physically change the track's direction. Made of strong materials, they resist heavy loads. However, over time, wear and tear can compromise their effectiveness. Regular inspections are essential but can be overlooked, leading to maintenance challenges. Understanding these components sheds light on their importance in safe rail operations.

This bar chart represents the different types of switch stands used in rail systems, showing the number of each type implemented.

A switch stand is a vital component in rail systems. It helps control the direction of train tracks. When trains need to change tracks, the switch stand is manually or mechanically operated. It pivots the track, allowing trains to safely divert to another route. The design is often simple, yet effective, often made of sturdy materials.

Operations are not always flawless. Humans can make mistakes when aligning tracks. Weather conditions can affect performance too. A snowstorm might freeze the mechanism, making it difficult to switch. Regular maintenance is crucial to ensure safety and efficiency. Sometimes a sudden failure occurs, leading to delays and accidents. Train operators must be vigilant and check switch stands regularly.

Switch stands also come with limitations. They are not foolproof. In high traffic areas, they can wear out quickly. The need for constant oversight is apparent. There is always room for improvement in technology. Automated systems could enhance reliability. Until then, manual check-ups remain essential. Observing how they function can offer insights into future innovations.

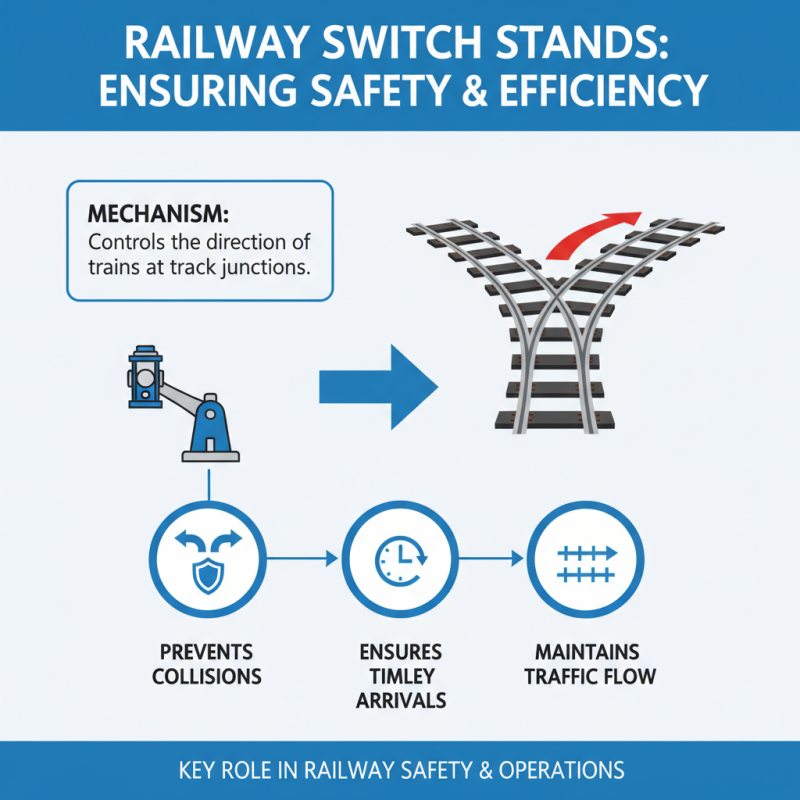

Switch stands play a crucial role in railway safety. They are mechanisms that control the direction trains take at junctions. By allowing trains to switch tracks, these stands help maintain the flow of rail traffic. This prevents collisions and ensures timely arrivals at stations.

Proper maintenance of switch stands is vital for smooth operations. Disruptions often occur due to neglect, leading to severe accidents. Regular inspections can detect wear and tear. Such efforts are essential to protect both passengers and freight. If a switch stand fails, it can derail an entire train.

Moreover, human errors happen. Operators may misjudge switch positions. This possibility underscores the need for clear indicators. Visual signals can guide conductors, minimizing risks. Training employees enhances their awareness. A well-informed team can prevent accidents caused by misunderstandings. Ultimately, the importance of switch stands cannot be overstated in preserving safety on the rails.

Maintenance and inspection of switch stands are crucial in rail systems. Regular checks ensure that these critical components function properly. Studies show that nearly 20% of switch failures are linked to inadequate maintenance practices. This highlights the need for rigorous inspection routines.

Inspectors should focus on several key areas. Moving parts must be lubricated routinely to prevent wear. Corrosion can compromise materials, so it should be assessed frequently. Reports indicate that 30% of switch malfunctions stem from rust. This underscores the importance of preventative measures.

Despite these practices, gaps still exist. Some inspections may overlook subtle signs of wear. Crew members might miss the frequency of necessary checks. Data shows that timely maintenance could reduce failures by up to 50%. Identifying and addressing these issues is vital for operational safety.