Choosing the right Bolted Crane Rail Clip is crucial for safe and efficient operations. In industrial settings, the integrity of crane rail systems directly impacts productivity. According to industry reports, improper rail clip selection can lead to significant downtime and costly repairs.

The right Bolted Crane Rail Clip ensures stability and prevents wear. Different materials and designs serve various load requirements. For instance, high-load environments may require clips with specific tensile strength. Yet, many operators overlook these specifications, risking performance and safety.

Reflecting on the choices available can be daunting. Standard clips may seem convenient, but they might not fit unique operational demands. A thorough evaluation is essential. Consider factors like material quality, load capacities, and installation ease. Making an informed decision benefits both safety and efficiency.

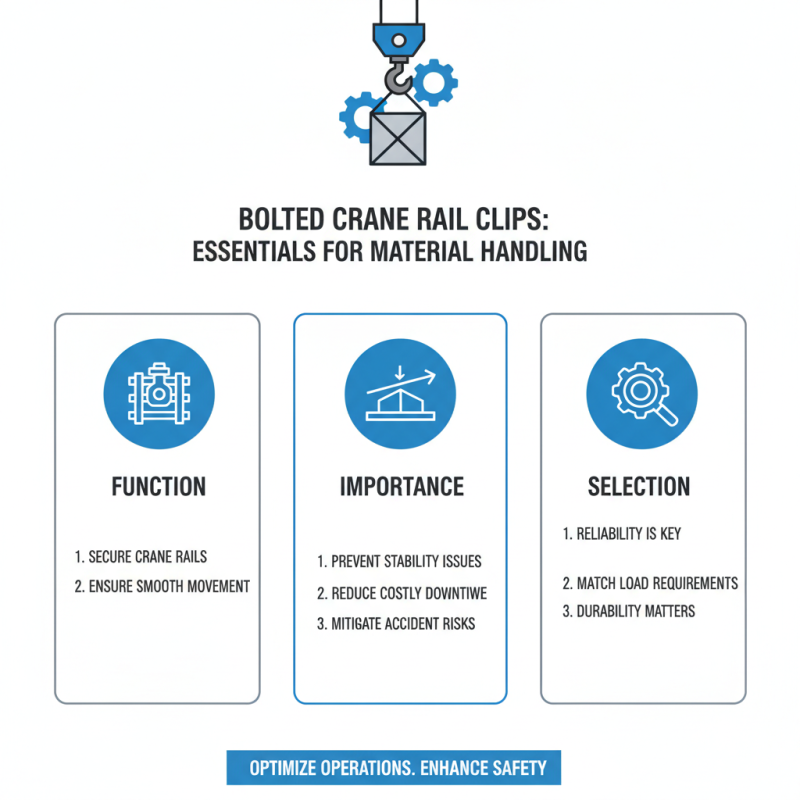

Bolted crane rail clips play a crucial role in material handling. They secure crane rails, ensuring smooth movement of heavy loads. Without reliable clips, operations can suffer from stability issues. This can lead to costly downtime and even accidents. Understanding their importance is key to selecting the right clip.

When choosing a bolted crane rail clip, consider the material. Durability is a must. Look for options that withstand environmental stress. The right size is vital, too. Clips must fit perfectly to avoid shifting during operations.

Tip one: always assess the weight capacity. You don't want to overload your clips. Tip two: check for corrosion resistance. Clips exposed to elements need to endure. Remember, inadequate clips can lead to failure. Not every option fits all needs, so careful selection is critical.

When selecting crane rail clips, understanding load capacity is essential. The right clip must support the weight it will carry. Consider the maximum load your system will handle. If you underestimate weight demands, it can lead to failure. Clips should fit snugly along the rail, avoiding excessive movement during operation. Each clip plays a role in maintaining stability under load.

Material choice is another critical factor. Clips made from durable materials ensure longevity. However, you might overlook corrosion resistance. Harsh environments can deteriorate clips faster than expected. Additionally, inspect the design of the clips. Some may not accommodate specific rail types or profiles. A poor fit can reduce safety and performance, leading to costly repairs. Always do your homework. Evaluating various options may feel overwhelming, but it’s necessary.

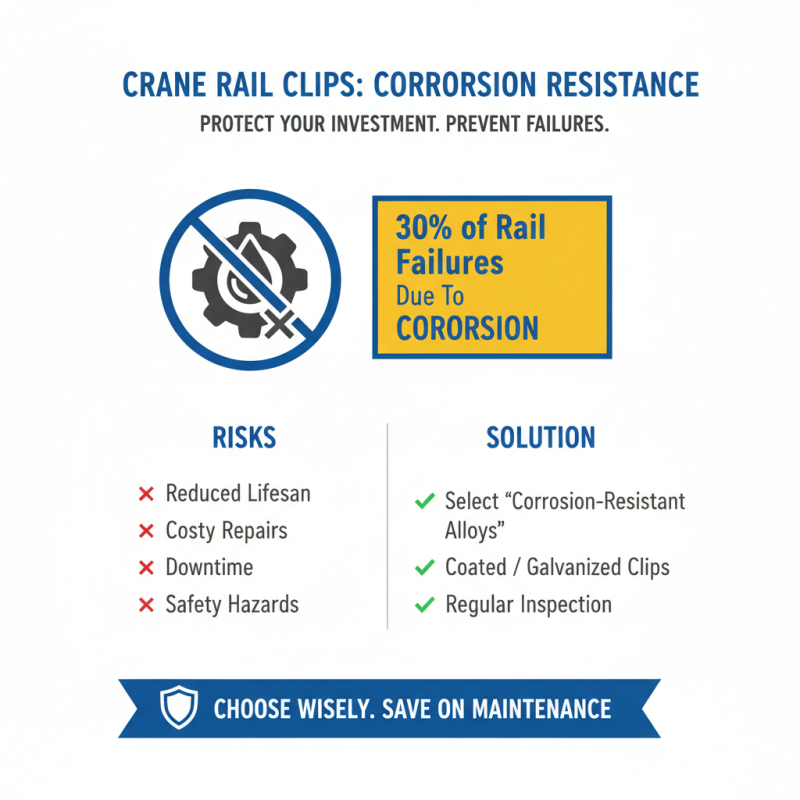

When selecting bolted crane rail clips, material corrosion resistance is crucial. Corrosion can significantly reduce the lifespan of these components, leading to costly repairs. According to industry reports, nearly 30% of rail failures can be traced back to corrosion-related issues. Choosing the right alloy can mitigate this risk.

Stainless steels and aluminum alloys are popular choices. These materials resist rust and deterioration. However, not all stainless steels perform the same in various environments. For example, Type 304 stainless offers moderate corrosion resistance but is less effective in marine settings. Type 316, on the other hand, excels in saltwater applications.

Cost considerations can complicate the decision-making process. Some alloys may initially seem more expensive, but they can save money over time. For instance, a corrosion-resistant clip may cost 15% more upfront but could extend service life by up to 50%. This consideration is often overlooked. Many default to cheaper options without assessing long-term benefits. Selecting the right alloy is a balance of immediate cost and future performance.

When selecting bolted crane rail clips, the installation method is crucial for efficiency and safety. An improper installation can lead to dangerous situations. For instance, a clip that isn't securely fastened may loosen over time. Regular inspections help, but they can be overlooked in busy environments. This can lead to increased wear on rail systems, ultimately deteriorating their performance.

Evaluating different installation techniques is essential. Some methods may take longer, but they ensure a more secure fit. Simple tasks, like checking alignment, can become complicated when shortcuts are taken. Workers sometimes rush the process, believing speed is more important than precision. This mindset can lead to mistakes, requiring costly corrections in the long run. Ensuring that every clip is installed correctly should be prioritized. Otherwise, the safety of the entire crane system can be compromised.

When selecting crane rail clips, understanding industry standards and compliance requirements is crucial. According to the International Organization for Standardization (ISO), crane rail clips must meet specific safety and performance metrics. These standards aim to ensure structural integrity during heavy loads and varying environmental conditions. Regular compliance with these metrics can mitigate risks in industrial settings.

Durability is a key aspect as well. A recent report by the American National Standards Institute (ANSI) revealed that improperly specified clips can lead to premature failures. Such failures not only hinder operations but can also cause costly downtimes. Many projects overlook the importance of material selection, assuming that all clips perform equally. However, steel grades and coatings matter significantly for longevity and safety.

Moreover, many companies fail to conduct regular inspections, which are vital to maintaining compliance. A study indicated that 30% of industrial accidents stemmed from equipment that did not meet safety regulations. Without ongoing assessments, businesses risk facing dire consequences. While many clips claim to fulfill standards, it is essential to verify independent testing results.