When it comes to construction and engineering projects, selecting the right components is crucial, and "Hot Dip Galvanised Bolts" stand out for their durability and corrosion resistance. According to industry expert Dr. Emily Carter, a leading authority in structural engineering, "The choice of bolts can significantly impact the long-term performance of any project, and Hot Dip Galvanised Bolts offer exceptional protection against the elements." This emphasizes the importance of choosing the right fastening solutions to enhance the overall longevity and reliability of structures.

In this article, we will delve into the top 10 tips for selecting Hot Dip Galvanised Bolts tailored to your specific project needs. Each tip is designed to guide you through the essential considerations, from understanding standard specifications to evaluating bolt sizes and load capabilities. By mastering these insights, you can ensure that your projects not only meet industry standards but also contribute to safer and more resilient constructions. The right choice of Hot Dip Galvanised Bolts is not just an accessory; it is a fundamental aspect of project success.

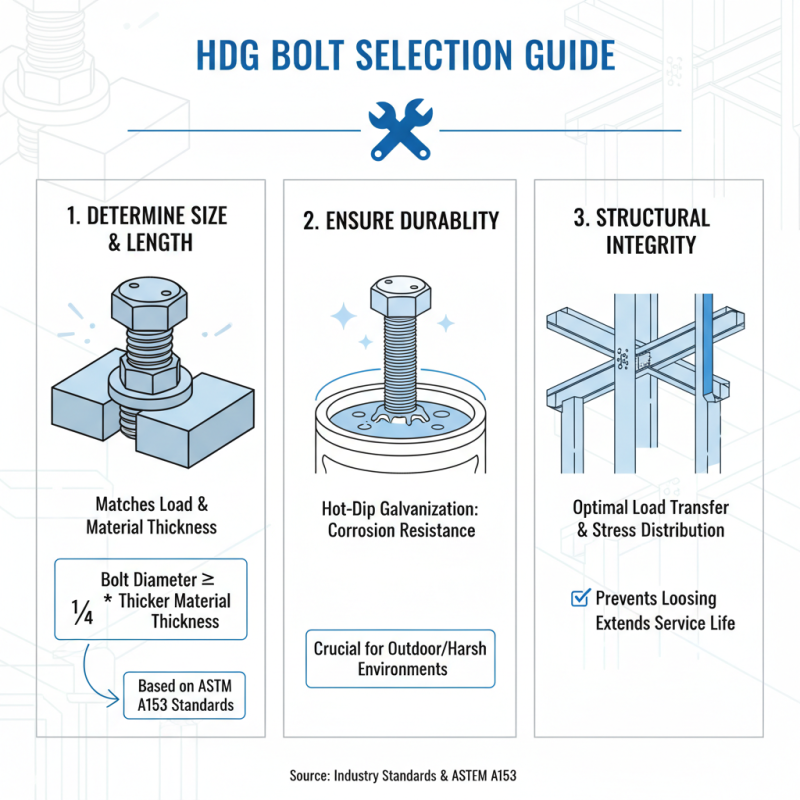

Hot dip galvanisation is a process that involves coating steel with a layer of zinc to protect it from corrosion. This technique provides a robust barrier against environmental elements, ensuring the longevity and durability of steel structures. The thick, adhereing coat makes hot dip galvanised bolts especially suited for outdoor applications where exposure to moisture and various chemicals is prevalent. One of the standout benefits of this method is its ability to extend the life of the bolts significantly, reducing maintenance needs and costs over time.

When selecting hot dip galvanised bolts for your project, one crucial tip is to assess the specific environmental conditions they will face. For instance, if the bolts are intended for marine applications, ensure they have an extra protective layer to withstand saltwater corrosion. It's also essential to consider the bolt size and thread type to match your project requirements, as compatibility plays a vital role in structural integrity.

Another important tip is to check the quality of the galvanisation. Not all hot dip galvanised products are created equal; some may not meet the necessary standards that ensure adequate protection. Always inquire about the galvanisation thickness and look for certifications that guarantee it meets industry regulations. By paying attention to these details, you can select bolts that not only provide immediate reliability but also contribute to the long-term success of your projects.

When embarking on a construction or manufacturing project, selecting the appropriate hot dip galvanized (HDG) bolts is crucial for ensuring durability and structural integrity. One of the primary considerations is determining the right bolt size and length for your specific application. According to industry standards, such as those outlined in ASTM A153, the size of the bolt thread must correspond to the load requirements and material thickness of the assemblies being joined. For instance, a typical rule of thumb is to use bolts that have a diameter of at least one-fourth the thickness of the thicker material being joined, ensuring optimal load transfer and stress distribution.

Additionally, the length of the bolt plays a significant role in the effectiveness of fastening. It should accommodate the combined thickness of all materials being joined, while also providing enough thread engagement for securing the assembly without the risk of stripping. Data from the American Institute of Steel Construction suggests that a minimum of six threads should be engaged for proper load-bearing capacity, especially in high-stress environments. Choosing the correct length not only facilitates stronger connections but also counters issues related to bolt loosening over time, which can be exacerbated by improper sizing. Therefore, precise calculations and considerations are essential to achieve a reliable and safe fastening solution for your project.

When selecting hot dip galvanised bolts for your projects, it's essential to evaluate the specific environmental conditions they will face. Corrosion resistance is a significant factor because it directly impacts the longevity and structural integrity of the assembly. Galvanised bolts offer a protective zinc coating, which acts as a barrier against moisture and corrosive agents. However, the effectiveness of this coating can diminish in harsh environments, such as marine or industrial settings where exposure to saltwater, chemicals, or pollutants is prevalent.

Consider the geographical location and the operating conditions of the project when choosing bolts. For instance, in coastal areas, the saline environment may necessitate additional protective measures or specialized coatings beyond standard galvanisation. Similarly, if the bolts will be subjected to high humidity or temperature fluctuations, those conditions can accelerate corrosion.

Assessing these factors thoroughly ensures that you choose the most suitable hot dip galvanised bolts, thereby safeguarding your project's durability and performance over time.

When selecting hot dip galvanised bolts for your projects, understanding load capacity and strength requirements is paramount. These factors determine how well the bolts can withstand the forces they will encounter in their application. It's essential to assess the specific loads that will be applied, including tensile, shear, and bearing loads. This ensures that the chosen bolts provide adequate safety margins and functionality without compromising structural integrity.

One critical tip is to consult the manufacturer's specifications for load ratings of the bolts you are considering. Make sure to select bolts that meet or exceed the load requirements of your project. Additionally, consider the environment in which the bolts will be used, as factors such as temperature, moisture, and potential corrosive elements can impact their performance.

Another important consideration is the bolt diameter and length, which must be aligned with the design requirements of your project. A larger diameter can generally handle more load, while the length will affect the embedment into the materials being fastened. Finally, when in doubt, it’s beneficial to consult with an engineer or a professional to ensure the bolts selected perfectly match the project's demands, thereby ensuring safety and durability.

| Tip Number | Tip Description | Load Capacity (KN) | Material Strength (MPa) | Corrosion Resistance Class |

|---|---|---|---|---|

| 1 | Assess project requirements for load-bearing capacity. | 50 | 400 | C4 |

| 2 | Select the appropriate diameter for bolts based on load. | 80 | 450 | C3 |

| 3 | Check the environmental conditions affecting corrosion. | 60 | 500 | C5 |

| 4 | Consider the length needed for optimal installation. | 70 | 600 | C2 |

| 5 | Verify bolt grade and tensile strength rating. | 90 | 700 | C4 |

| 6 | Ensure compatibility with other materials used. | 85 | 650 | C3 |

| 7 | Consult installation guidelines for torque specifications. | 95 | 600 | C5 |

| 8 | Review application-specific industry standards. | 75 | 550 | C4 |

| 9 | Consider local regulations regarding materials. | 65 | 500 | C2 |

| 10 | Plan for regular maintenance and inspection intervals. | 100 | 750 | C5 |

When selecting hot dip galvanised bolts for your projects, choosing reputable manufacturers and suppliers is crucial to ensure quality assurance. One of the first steps in this process is to conduct thorough research on potential suppliers. Look for companies that specialize in fasteners and have a proven track record in the industry. Reading customer reviews and checking testimonials can provide valuable insights into their reliability and the quality of their products.

Additionally, consider suppliers that have relevant certifications to guarantee their products meet industry standards. Certifications such as ISO or ASTM indicate adherence to specific quality benchmarks. Engaging with suppliers who are transparent about their manufacturing processes and materials will also contribute to making an informed decision. By prioritising manufacturers who demonstrate a commitment to quality through their operations, you can ensure that the hot dip galvanised bolts you purchase will perform optimally and withstand the test of time in your projects.