In the intricate world of industrial piping systems, one crucial element often goes unnoticed yet plays a vital role in ensuring operational stability: the Pipe Support Base Plate. As noted by industry expert James Anderson, a leading mechanical engineer with over two decades of experience in the field, "A well-designed Pipe Support Base Plate not only stabilizes the piping but also enhances the overall efficiency and safety of industrial operations." This underscores the importance of selecting the right type of base plate for specific industrial applications.

The effectiveness of Pipe Support Base Plates can significantly influence the longevity and performance of piping systems. With a myriad of designs available, understanding the differences and applications of these base plates is essential for engineers and project managers alike. Whether dealing with high-temperature environments or heavy load requirements, choosing the appropriate base plate type can mitigate risks associated with pipe movement and system integrity. In this article, we will explore the top 10 Pipe Support Base Plate types that offer effective solutions for industrial needs, ensuring that systems are not only functional but also well-supported.

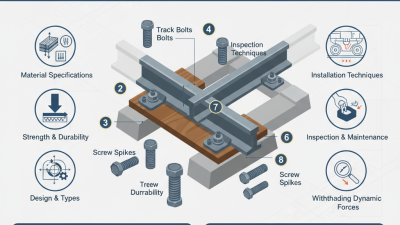

In industrial applications, pipe support base plates play a critical role in maintaining the stability and alignment of piping systems. These base plates are designed to distribute the load of the pipes evenly across the foundation, helping to prevent damage to both the pipes and the infrastructure. Different types of base plates are available to cater to various requirements, including materials, sizes, and load capacities. When selecting a base plate, considerations should include the environmental conditions, weight of the pipes, and the specific layout of the piping system.

Tips: Always inspect the base plate for any signs of wear or corrosion prior to installation. Choosing a base plate that is resistant to the specific chemicals and temperatures present in your application can greatly enhance the longevity of your piping system.

Proper installation of pipe support base plates is also crucial for optimal performance. Ensuring that the base plate sits level and is anchored securely can mitigate the risk of misalignment or shifting under load. It is advisable to consult with engineering guidelines to meet industry standards and best practices while installing these supports.

Tips: Regular maintenance checks can prevent potential failures; consider a schedule for inspections that aligns with your maintenance protocols to ensure the integrity of your piping system.

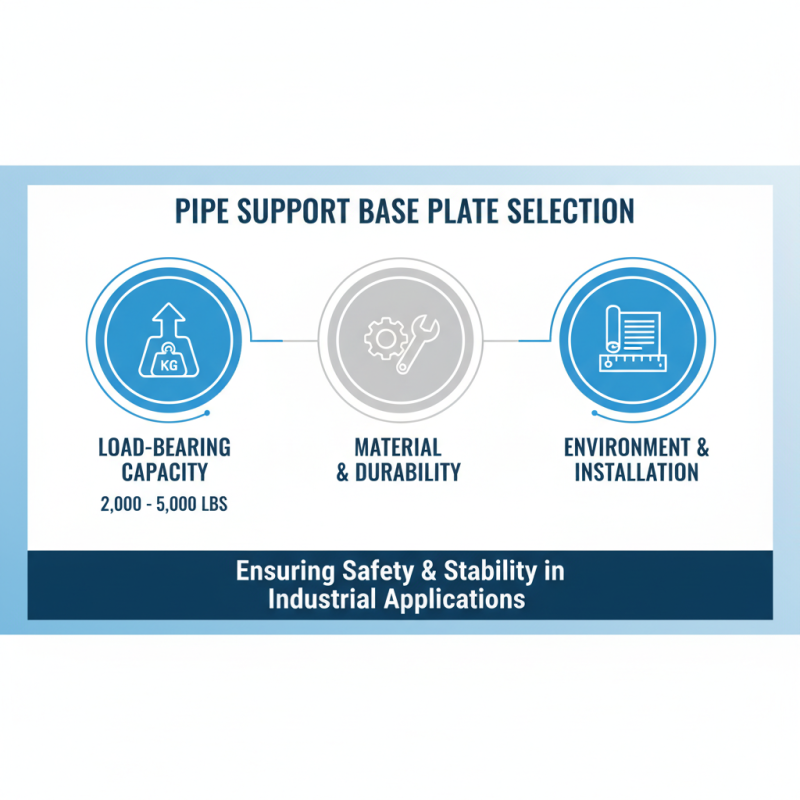

When selecting pipe support base plates, several key factors are essential for ensuring optimal performance in industrial applications. One primary consideration is load-bearing capacity. According to industry reports, the typical load-bearing requirements for pipe supports can range significantly, often between 2,000 to 5,000 pounds, depending on the size and material of the piping systems being supported. This variably emphasizes the importance of selecting base plates that can adequately handle these weights, ensuring safety and stability within the infrastructure.

Another critical factor is the environmental conditions where the pipe supports will be installed. Corrosive environments, such as those found in chemical processing plants, necessitate the use of base plates made from materials that can withstand adverse conditions. For instance, stainless steel base plates are often preferred in these scenarios, as they exhibit high resistance to corrosion and can significantly extend the lifespan of the installation. According to studies, using appropriately rated materials can increase service life by up to 30%, thereby reducing the need for frequent replacements and maintenance.

Finally, the ease of installation and maintenance also plays a vital role in the selection process. Base plates that facilitate quick installation not only enhance efficiency but also minimize downtime during plant operations. Industry data indicates that incorporating user-friendly designs can reduce installation times by approximately 25%, making them a more desirable choice for industrial projects. These considerations are critical to ensuring that the selected pipe support base plates meet the operational demands and longevity expected in modern industrial systems.

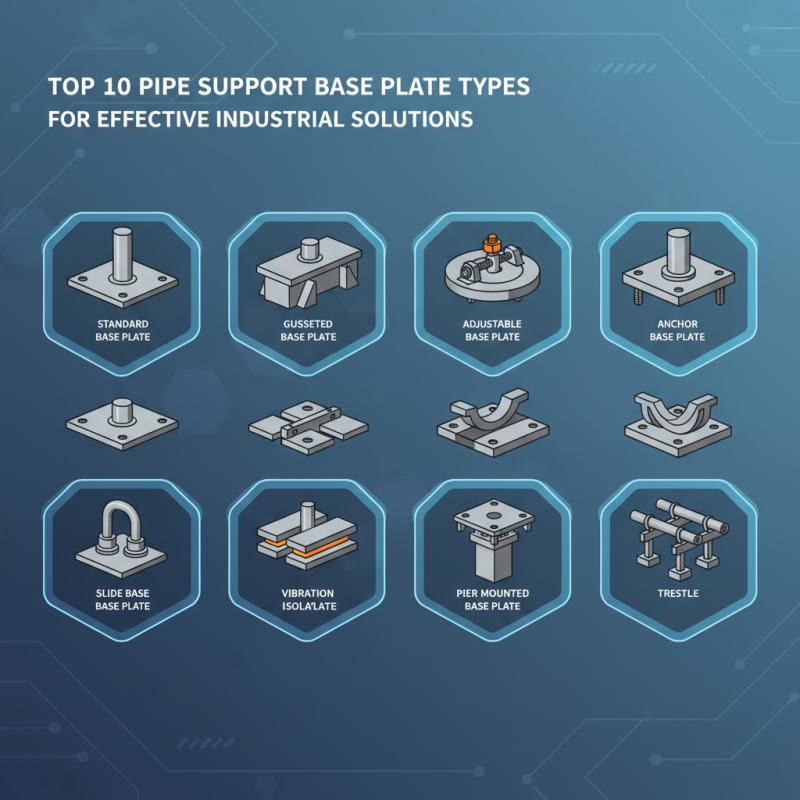

In the industrial sector, the selection of the appropriate pipe support base plate is crucial for ensuring the stability and durability of piping systems. According to a report by the Industrial Piping Association, approximately 30% of piping failures can be attributed to inadequate support structures. This highlights the necessity of understanding different types of pipe support base plates and their specific applications. Common types include flat base plates, adjustable base plates, and anchored base plates, each designed to address unique loads and environmental conditions.

Flat base plates are often used in structural applications where load distribution is essential. These plates create a wide support area, reducing the risk of failure due to localized stresses. On the other hand, adjustable base plates offer the flexibility to accommodate varying installation heights and are commonly used in maintenance-intensive areas where piping layouts may change over time. Anchored base plates are particularly beneficial in environments prone to seismic activity, providing enhanced stability by securing the pipe system against lateral movements. According to data from the American Society of Mechanical Engineers (ASME), proper selection and installation of these supports can reduce maintenance costs by up to 20%, demonstrating the value of investing in the right materials for industrial applications.

| Base Plate Type | Material | Load Capacity (lbs) | Application |

|---|---|---|---|

| Standard Steel Base Plate | Steel | 2000 | General piping support |

| Padded Base Plate | Aluminum | 1500 | Supports with vibration dampening |

| Heavy Duty Base Plate | Hot-dip galvanized steel | 4000 | Heavy equipment installations |

| Adjustable Base Plate | Stainless steel | 1000 | Applications with height variations |

| Anchor Base Plate | Concrete | 3000 | Fixed point installations |

| Welded Base Plate | Mild steel | 2500 | Permanent installations |

| U-Shaped Base Plate | Plastic | 800 | Chemical installations |

| Plate with Flange | Aluminum | 1200 | Industrial piping |

| Isolation Base Plate | Fiberglass | 600 | Corrosion-resistant applications |

| Floating Base Plate | Polymer composite | 700 | Temperature-sensitive applications |

The selection of materials for pipe support base plates is crucial for ensuring structural integrity and longevity in industrial applications. A comprehensive analysis of different substrates reveals that carbon steel remains the predominant choice due to its balance of strength, ductility, and cost-effectiveness. According to a recent industry report by the American Institute of Steel Construction, carbon steel base plates demonstrate a tensile strength of approximately 400 MPa, which makes them suitable for various load-bearing applications within industrial settings. However, their susceptibility to corrosion necessitates protective coatings or galvanization, especially in harsh environments.

In contrast, stainless steel base plates, while offering superior corrosion resistance and aesthetic appeal, come with a higher price tag. Their use is particularly favored in industries where hygiene and resistance to chemical exposure are paramount, such as food processing and pharmaceuticals. A report from the Steel Market Development Institute indicates that the lifetime cost of stainless steel components, when considering maintenance and replacement due to environmental factors, can offer significant savings in specific applications. Furthermore, composite materials are emerging as a viable alternative for lightweight and heavy-duty needs, providing a unique combination of strength and reduced weight. These innovative materials are identified to outperform traditional options under certain conditions, showcasing the evolving landscape of pipe support technology.

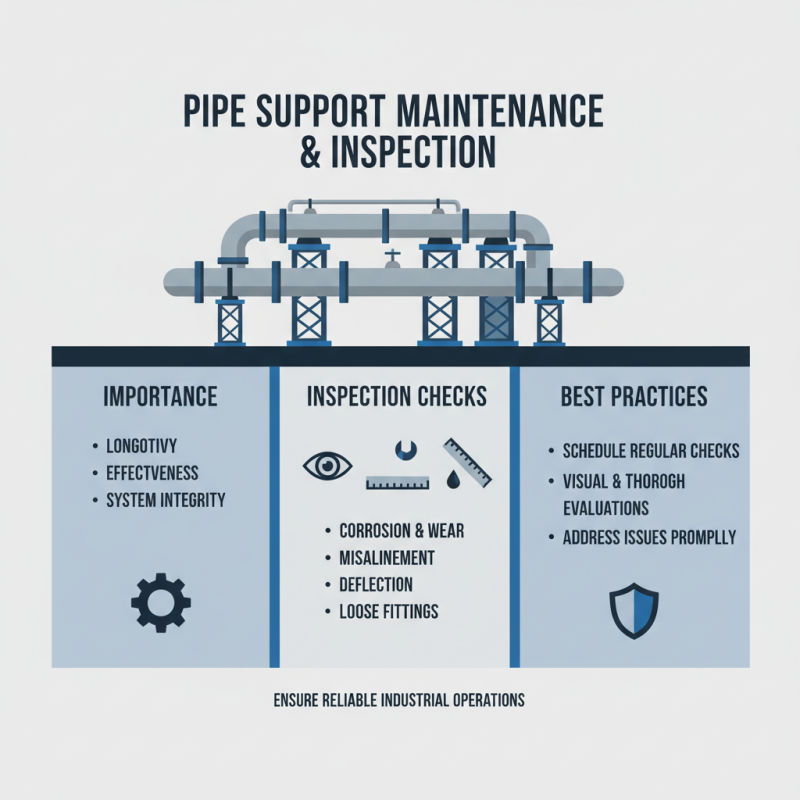

Proper maintenance and inspection of pipe support systems are essential to ensure their longevity and effectiveness in industrial applications. Regular checks should be scheduled to assess the condition of the pipe support base plates, brackets, and the overall alignment of the piping. Common inspection practices include looking for signs of corrosion, wear, or misalignment, which can compromise the integrity of the support system. Visual inspections should be complemented by more thorough evaluations, such as measuring deflection and checking for loose fittings, to ensure that the supports are functioning efficiently under operational stresses.

In addition to regular inspections, maintaining clear documentation of maintenance activities is critical. This documentation helps in tracking the history of repairs and replacements, allowing for better predictive maintenance strategies. It also ensures that all personnel are aware of the current status of the pipe support systems, which aids in preventing accidents or failures. Implementing a systematic approach to both maintenance and inspection can significantly enhance the reliability and safety of industrial piping systems, ultimately leading to reduced downtime and increased operational efficiency.