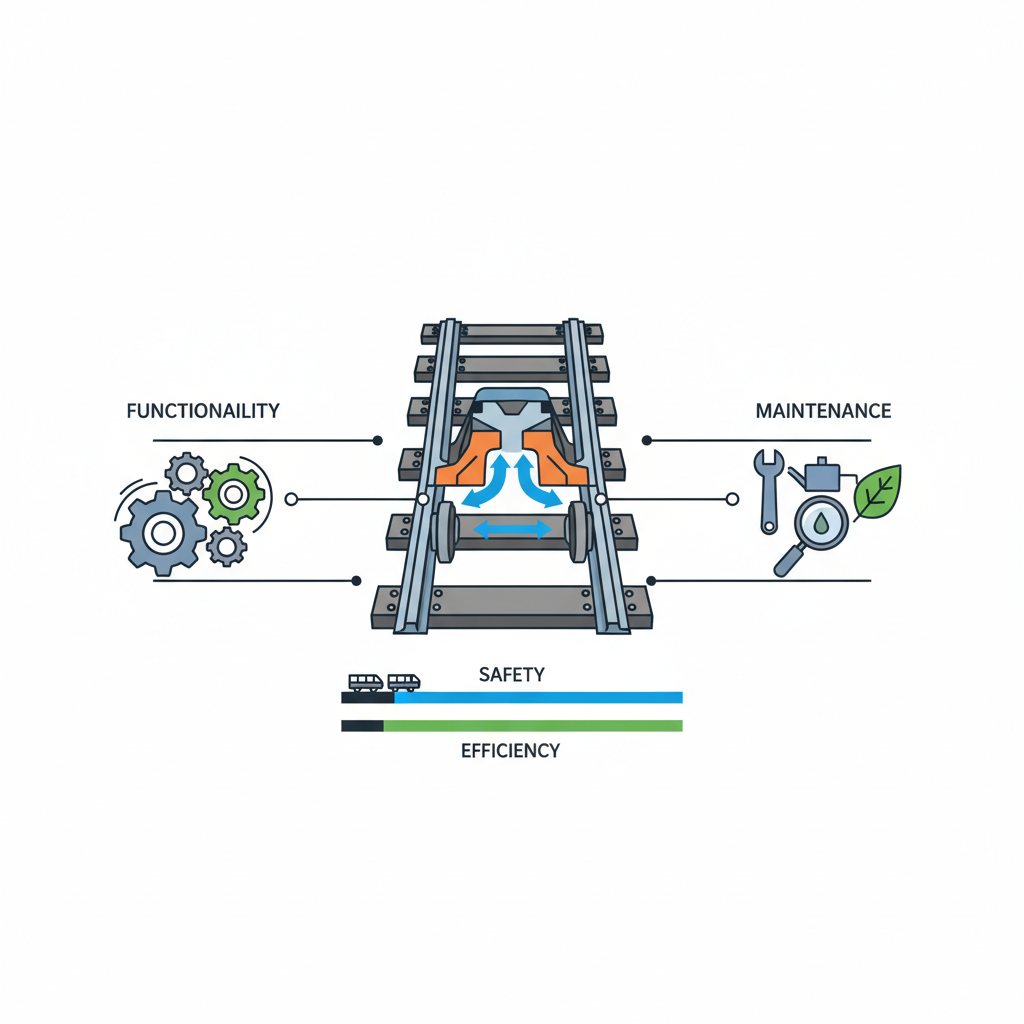

Railway frogs play a crucial role in the functionality of train tracks, facilitating the smooth transition of trains from one track to another while ensuring safety and efficiency. Understanding the intricate design and operation of these essential railway components is vital for both railway professionals and enthusiasts alike. The railway frog, a device that allows for the divergence of train lines, is a unique engineering marvel that requires regular maintenance and attention to detail.

In this exploration of railway frog functionality and maintenance, we will delve into the key aspects of how these components work, the best practices for their upkeep, and the importance of their role in overall railway safety. By examining the mechanisms and materials involved in railway frogs, we can appreciate their significance in providing reliable service and minimizing disruptions in rail networks. This guide aims to equip readers with the essential knowledge needed to understand and maintain railway frogs effectively, ensuring the continued safety and efficiency of rail transportation systems.

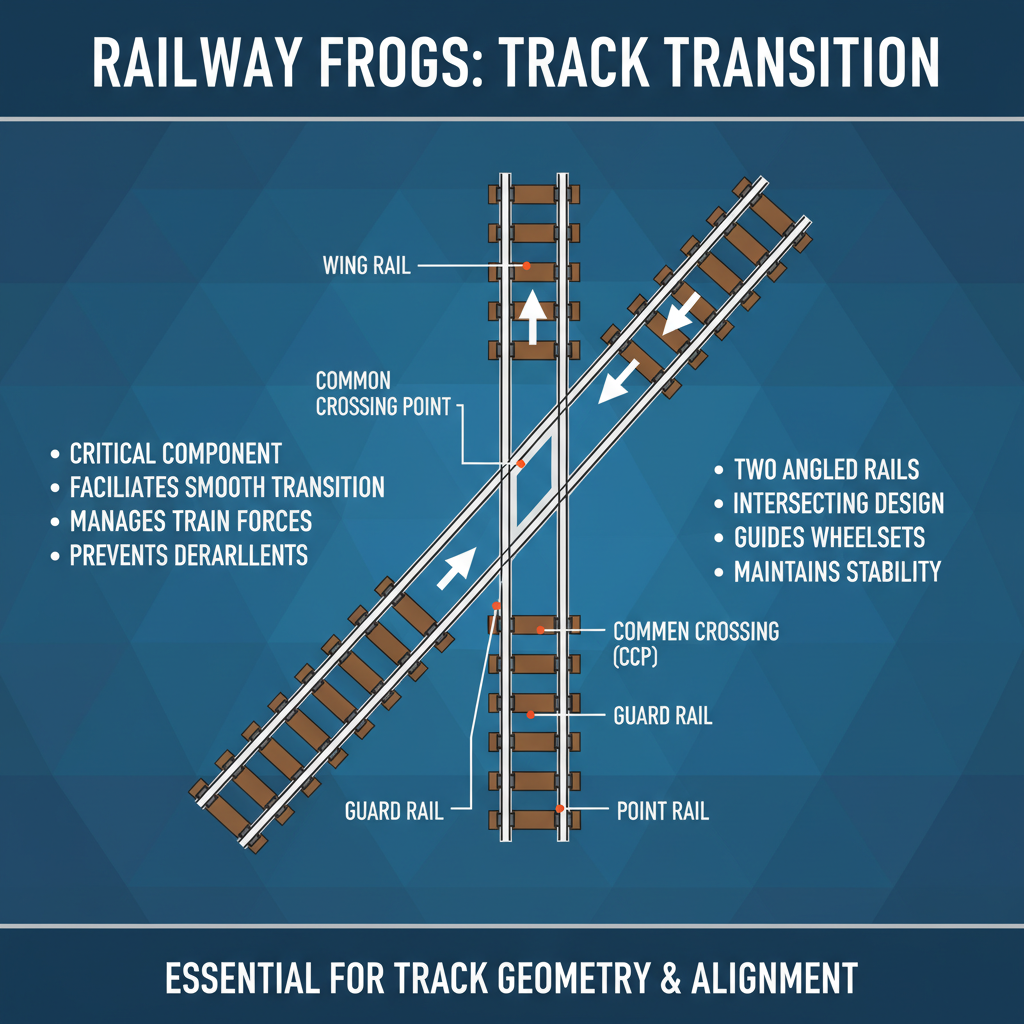

Railway frogs are critical components in rail infrastructure, facilitating the smooth transition of trains from one track to another. Understanding how frogs function involves recognizing their role in track geometry and alignment. A frog consists of two angled rails that intersect, allowing trains to switch tracks while maintaining stability. The design of a frog ensures that the wheelsets of a train can traverse the point where tracks meet, managing the forces exerted by moving trains to prevent derailments.

Maintenance of railway frogs is essential to ensure their reliability and safety. Regular inspections are necessary to identify wear and tear on the rail components, particularly at the flangeways where the wheels pass over the junction. Keeping frogs clean from debris and ensuring proper lubrication reduces friction, prolonging their lifespan. Additionally, timely replacement or repair of damaged frogs is crucial, as it prevents potential accidents and downtime on the rail network. By understanding both the functionality and maintenance of railway frogs, railway operators can enhance the efficiency and safety of their operations.

Railway frogs are critical components in rail systems, enabling trains to switch tracks safely and efficiently. There are several types of railway frogs, each designed for specific applications. The most common types include the single-track and double-track frogs. Single-track frogs are utilized where tracks converge or diverge at a single point, facilitating smooth transitions for trains on a singular line. In contrast, double-track frogs accommodate two tracks crossing each other, allowing for bi-directional rail traffic and enhancing the overall efficiency of the rail network.

Another important type is the movable-point frog, which features points that can adjust position to guide trains from one track to another. This type is especially useful in stations and junctions where the flow of trains is high and flexibility is essential. Additionally, the insulated frog is designed to prevent electrical contact between tracks, making it vital in electrified rail systems. Understanding the various types of frogs and their specific applications is crucial for effective maintenance and ensuring the safety and efficiency of rail operations.

Regular inspections and proper upkeep of these components can significantly reduce the risk of derailments and enhance the longevity of the rail infrastructure.

Railway frogs, also known as turnouts, are critical components in railroad systems, enabling trains to switch tracks seamlessly. Understanding the key elements of railway frogs is essential for efficient railway operation and maintenance. The primary purpose of a frog is to facilitate the safe and smooth transition of train wheels from one track to another while minimizing wear and tear. Key components of frogs include the frog point, wing rails, and closure rails. Each part plays a crucial role in guiding the train wheels, ensuring proper alignment and reducing the risk of derailment.

Advancements in technology are enhancing the inspection and maintenance practices associated with railway frogs. Recent developments aim to improve the precision and effectiveness of turnout inspections, which is vital for identifying potential issues before they become critical. Additionally, innovations in machining techniques are being implemented for the fabrication of frogs, ensuring they meet high standards of durability and performance. These improvements not only extend the lifespan of railway frogs but also contribute to safer and more efficient railway operations.

| Component | Function | Maintenance Tips | Common Issues |

|---|---|---|---|

| Railway Frog | Facilitates the crossing of train tracks | Regular inspections for wear and tear | Excessive wear, misalignment |

| Guard Rails | Prevents wheel flanging on turns | Check for rust and structural integrity | Rust, loosening |

| Frog Spring | Maintains contact between the frog and the wheels | Ensure proper tension is maintained | Loss of tension, corrosion |

| Switch Mechanism | Allows trains to switch tracks | Lubricate moving parts regularly | Sticking, misalignment |

| Bolts and Fasteners | Secure all the components together | Check for tightness and replace as needed | Loose or missing bolts |

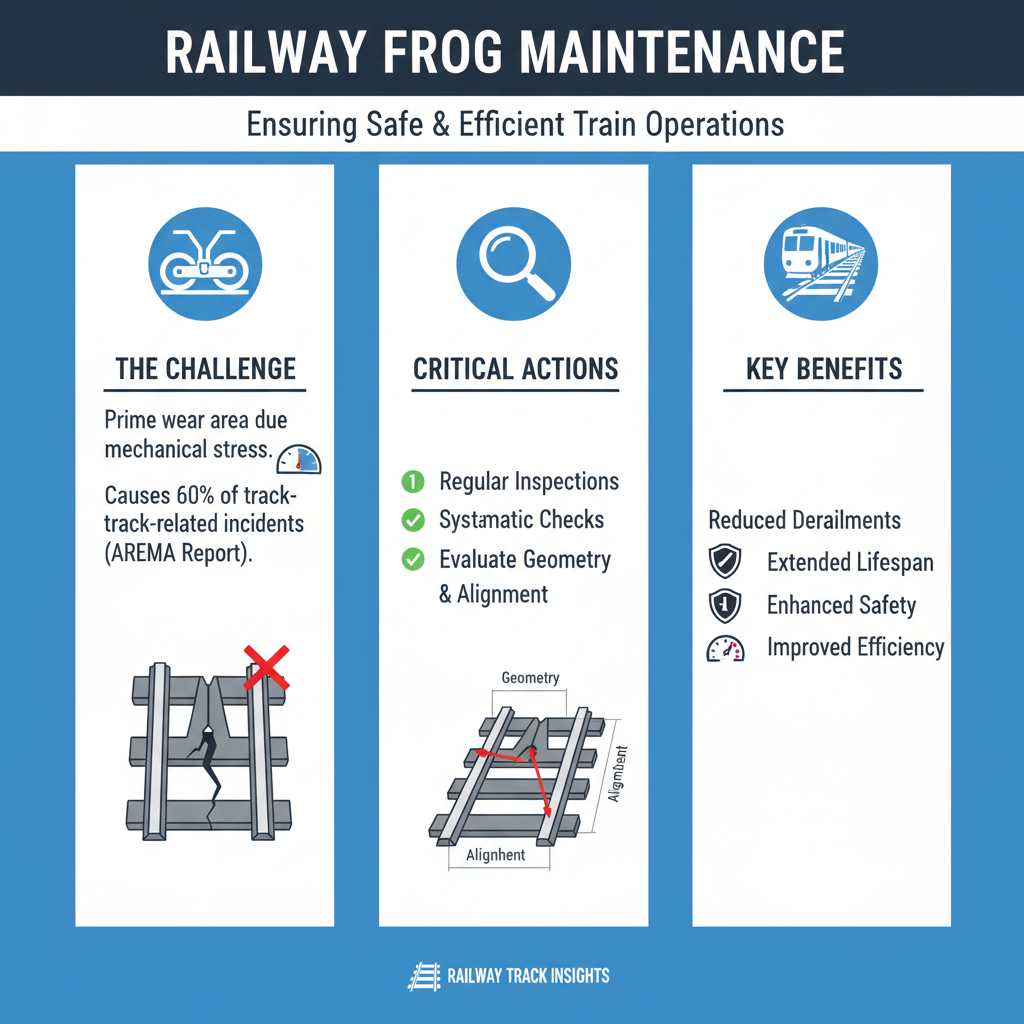

Effective maintenance of railway frogs is critical for ensuring safe and efficient train operations. Regular inspections are essential, as frogs are prime areas subject to wear due to constant mechanical stress. According to a report by the American Railway Engineering and Maintenance-of-Way Association (AREMA), approximately 60% of track-related incidents can be attributed to poor frog maintenance. This underscores the need for systematic checks, including evaluating the geometry and alignment of frogs to reduce derailments and extend their lifespan.

Key maintenance practices involve timely lubrication and timely replacement of any worn components. The Federal Railroad Administration (FRA) recommends lubricating the moving parts of frogs at least every 500 miles to minimize friction and wear. Furthermore, using advanced technologies such as ultrasonic testing can help detect internal flaws in frog structures before they result in failure. By integrating both routine and advanced maintenance approaches, rail operators can optimize frog functionality, ensuring smoother transitions for trains and enhancing overall operational efficiency.

Railway frogs, critical components in track switching, often face common issues that require timely troubleshooting to ensure safety and efficiency in rail operations. One prevalent issue involves wear and tear due to the constant passage of trains, leading to misalignments that can cause derailments. Regular inspections, especially during seasonal transitions like winter, are essential for identifying and addressing these issues. During the recent operational testing phase of the Huai-Xing Intercity Railway section, maintenance crews were actively engaged in checking the functionality of railway frogs to ensure smooth transitions between tracks.

Another common concern is the accumulation of debris and ice around the frog areas, which can hinder proper function. This was highlighted by the proactive measures undertaken by railway crews in the Daxinganling region, who conducted thorough inspections of signal equipment amidst harsh winter conditions. Effective troubleshooting includes implementing preventive maintenance schedules and utilizing appropriate tools to clear obstructions, ensuring that all components, including frogs, perform optimally. By focusing on these common challenges and maintaining rigorous maintenance standards, railway operators can enhance overall safety and operational reliability.