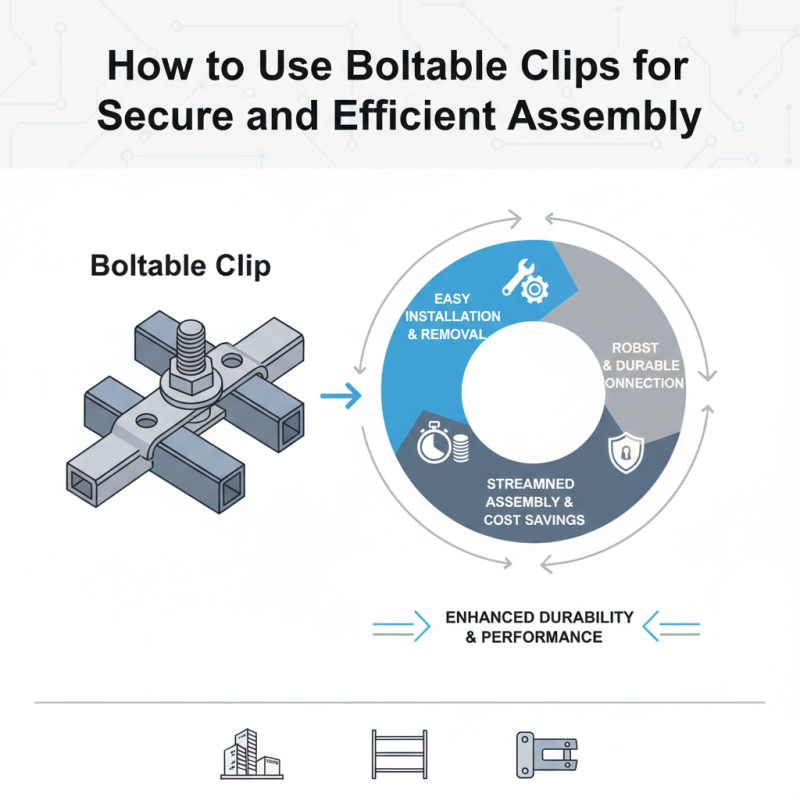

In the realm of modern assembly techniques, the use of innovative fastening solutions has become increasingly essential for achieving both efficiency and security. Among these solutions, the Boltable Clip stands out as a versatile and reliable component that facilitates the assembly of various structures while ensuring a robust connection. This introduction explores the key attributes and benefits of employing Boltable Clips in assembly processes, highlighting their role in enhancing durability and performance.

Boltable Clips are specially designed fasteners that offer a straightforward yet effective means of joining components with precision. Their unique design allows for easy installation and removal, making them ideal for applications where frequent adjustments or modifications are necessary. Furthermore, the ability to secure components tightly without the need for extensive tools not only streamlines assembly but also minimizes labor costs and time. As we delve deeper into the specifics of utilizing Boltable Clips, it becomes clear that they are an indispensable tool for anyone looking to enhance their assembly practices in a secure and efficient manner.

Boltable clips are essential components in various assembly applications, providing secure fastening solutions across industries such as automotive, aerospace, and construction. These clips come in a variety of designs, each tailored to specific use cases and material types. The most common types include captive bolts, which integrate a rotating mechanism to secure the clip firmly into place, and threaded clips that offer the flexibility of adjustment. According to the International Fastener Authority, approximately 60% of all fastener-related failures can be attributed to improper application, underscoring the necessity of understanding the specifications and appropriate uses of boltable clips.

When selecting boltable clips, it is crucial to consider specifications such as load capacity, material strength, and resistance to environmental factors. For instance, steel clips with a high tensile strength can withstand significant loads, making them suitable for heavy-duty applications. Conversely, clips made from polymers may be effective in environments that are corrosive or require lightweight solutions. A report by the Fastener Research Council highlights that the right clip material can enhance longevity and performance by 30%, significantly reducing maintenance costs in assembly projects. By leveraging the right types of boltable clips, engineers can optimize assembly efficiency and promote the reliability of their constructions.

Preparing materials for assembly with boltable clips involves several essential steps that ensure a secure and efficient process. First, it is crucial to select the right materials that will work harmoniously with the clips. This often involves assessing the thickness and type of the surfaces you are assembling. Ensuring the materials are clean and free of debris will create a reliable friction surface that enhances the grip of the clips. Additionally, if the materials are prone to movement or flexing, reinforcing them with additional supports may be beneficial to maintain stability during the assembly process.

Once the appropriate materials are selected and cleaned, measuring and marking the precise locations for the clips is the next vital step. Accurate measurements prevent misalignment, which can lead to weak joints or the failure of the assembly. Using a consistent method, such as a template or measuring tape, helps achieve uniformity in clip placement. After marking, pre-drilling holes may be necessary, depending on the clip design and the material being used. This preparation not only facilitates easier fastening but also reduces the risk of splitting or damaging the materials during assembly. By taking the time to prepare materials correctly, ensuring they are suitable for boltable clips, you can achieve a more robust and long-lasting assembly.

Installing boltable clips can significantly improve the efficiency and security of your assembly projects. Start by gathering all necessary tools and materials, including the clips themselves, a drill, and the appropriate fasteners. Begin by preparing the surfaces where the clips will be mounted. Ensure they are clean, dry, and free from debris to achieve a strong bond and proper alignment.

Once the surfaces are prepped, mark the locations for the clips according to your assembly plan. Carefully drill pilot holes in the marked spots to ensure accurate placement of the clips. After drilling, align the clips with the pilot holes, and secure them using the designated fasteners. It's important to tighten the fasteners evenly to maintain the stability of the assembly. Double-check each connection for strength and alignment, making adjustments as necessary before proceeding with the rest of the assembly.

In the final step, test the assembly to ensure it meets the necessary requirements for security and functionality. If any adjustments are needed, make sure to do so prior to using the assembled product. Following these steps will not only streamline your assembly process but also enhance the reliability of your final product.

When assembling structures using boltable clips, ensuring stability is paramount to achieving a successful outcome. First, it's essential to select the appropriate clip size and material that corresponds to the load and conditions of the assembly. Overloading or using unsuitable materials can result in decreased stability and potential failure. Before installation, verify that all components are free from damage, as any weakened parts can compromise the integrity of the entire assembly.

Another crucial aspect of ensuring secure assembly is the proper alignment of components before fastening. Misalignment can lead to uneven stress distribution, making the structure prone to wobbling or collapse. Take the time to adjust each piece and check that it fits snugly into the clip before tightening bolts. Using a torque wrench to apply the right amount of force can further enhance stability, as it prevents over-tightening, which can stress the materials and lead to failure over time. By following these tips, you can ensure a reliable and sturdy assembly with boltable clips.

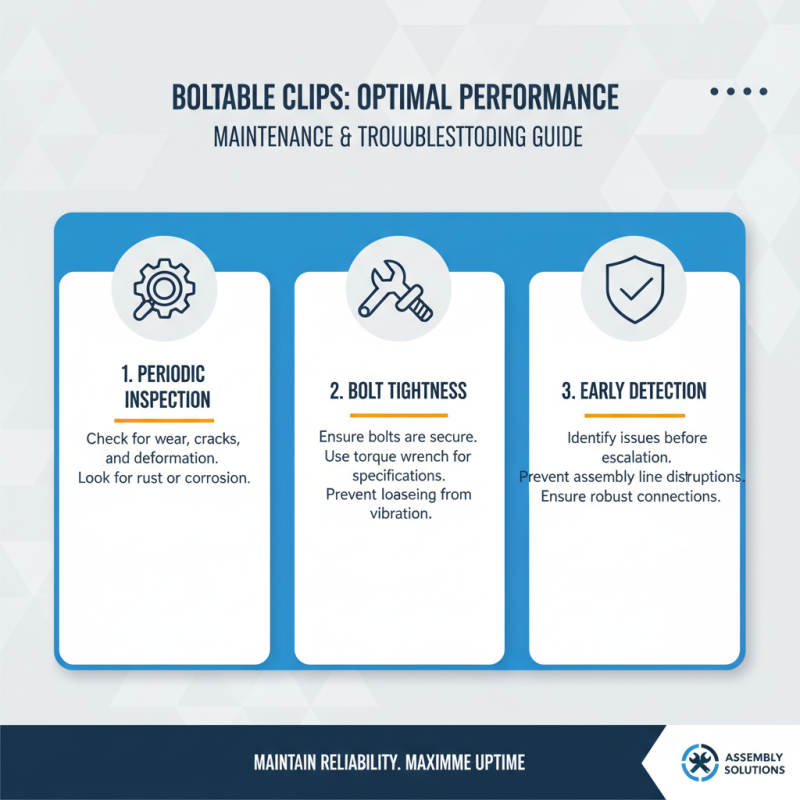

Boltable clips are vital components in various assembly processes, providing robust connections while allowing for ease of disassembly. However, like any mechanical component, their performance may be affected over time, necessitating regular maintenance and troubleshooting. To ensure optimal function, it is essential to inspect the clips periodically for wear and tear, as well as to check the tightness of the bolts securing them. These inspections will help identify any potential issues before they escalate, preventing disruptions in the assembly line.

In the event of performance issues, such as looseness or misalignment, troubleshooting boltable clips begins with disassembling the affected joint to assess the condition of the components. Look for signs of fatigue, such as deformation or cracks in the clips, and replace any damaged parts immediately. Additionally, ensure that the surfaces to which the clips are affixed are clean and free from debris; contaminants can lead to subpar performance. By addressing these factors proactively, users can maintain the reliability and efficiency of boltable clips in their assembly processes, minimizing downtime and enhancing overall productivity.