Buffer Stops, BF Stopper | Stop Buffer | End Stopper | Hydraulic Buffer

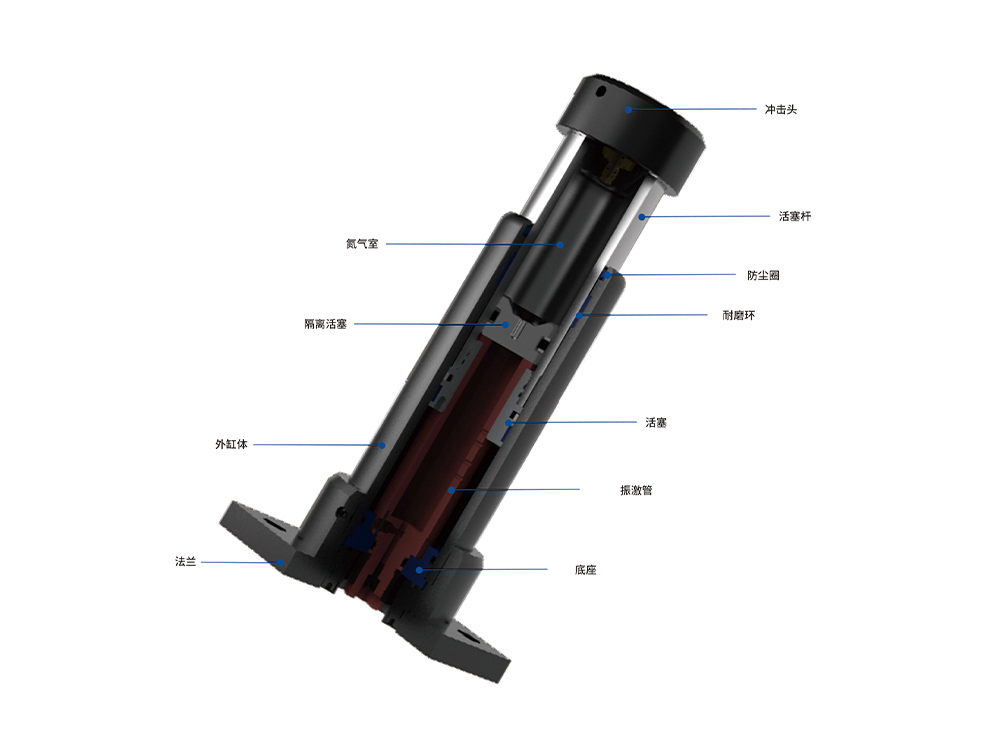

Features:

1. Cushioning:

Hydraulic buffers absorb and mitigate impact forces and vibrations during mechanical movement through hydraulic damping. This prevents damage to the mechanism caused by hard collisions.

2. Improved Stability:

By converting impact forces or vibrations into the flow of oil, hydraulic buffers enable mechanical equipment to stop smoothly when subjected to external forces. This enhances the stability and extends the service life of the equipment.

3. Equipment Protection:

Hydraulic buffers reduce the effects of vibration and impact forces, thereby lowering the failure rate of equipment, decreasing maintenance costs, and prolonging the equipment's operational lifespan.

4. No Rebound Effect:

Hydraulic buffers do not generate rebound forces after the buffering process is complete, eliminating the risk of secondary impact damage to the equipment.

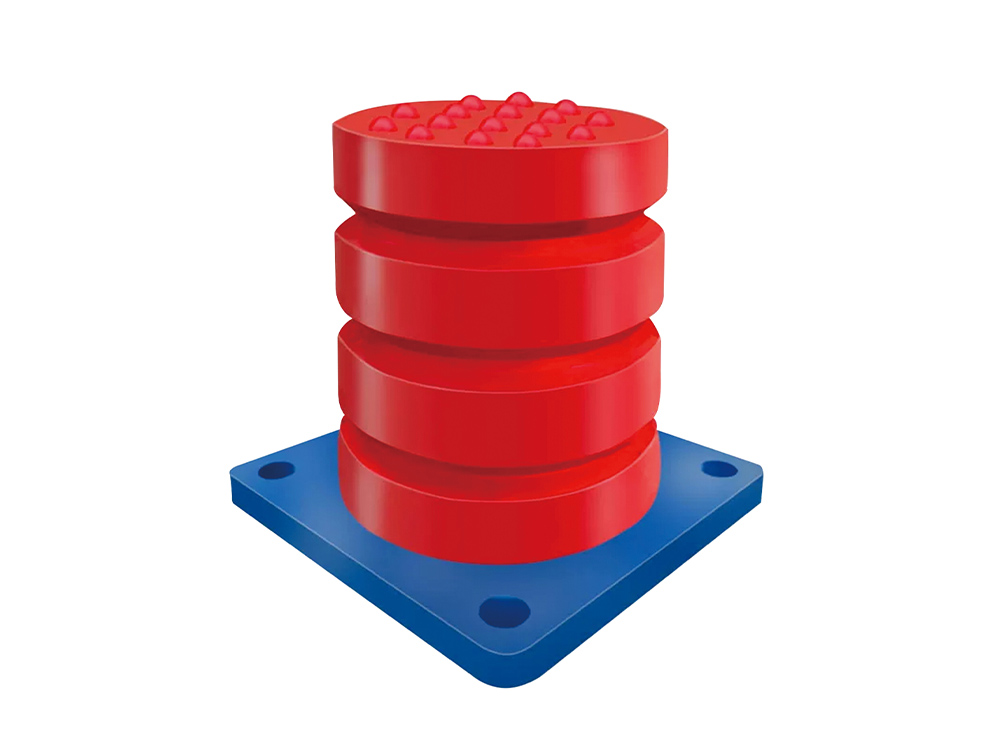

The polyurethane (PU) buffer utilizes the unique microporous bubble structure of polyurethane material to absorb and dissipate impact energy. During the impact process, it functions like a spring with multiple airbag dampers, effectively reducing vibration and shock.

Features:

● Lightweight: Easy to handle and install due to its low weight.

● Easy Installation: Designed for quick and straightforward setup.

● Maintenance-Free: Requires no ongoing maintenance, reducing operational costs.

● Excellent Cushioning: Provides superior shock absorption for enhanced performance.

● Impact Resistance: Highly durable and capable of withstanding significant impact forces.

● Safe and Reliable: Ensures consistent and dependable operation in various applications.

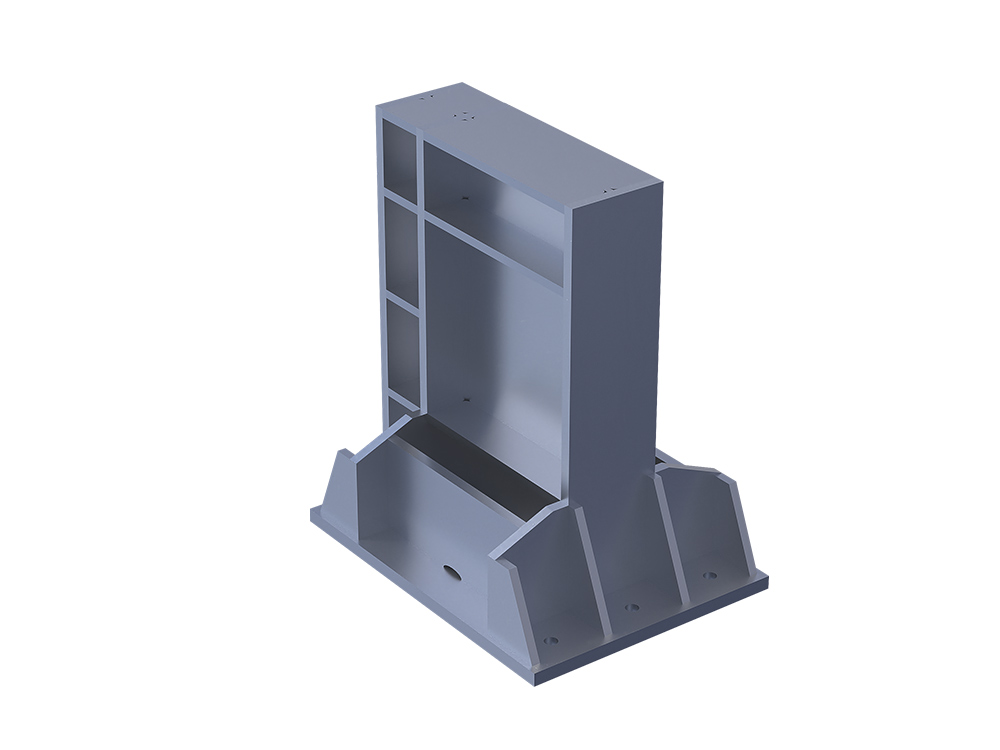

Product Overview

The buffer stop (also known as a crane runway bumping post) is a heavy-duty safety device installed at the terminal ends of crane tracks to prevent overtravel and derailment of crane equipment. Constructed from high-strength steel, it serves as a robust physical barrier, absorbing kinetic energy and ensuring safe operation in industrial environments.

Primary Material: High-grade carbon steel (e.g., Q235B, S355JR) or alloy steel, selected for exceptional tensile strength, impact resistance, and durability.

Surface Treatment: Hot-dip galvanized or painted to enhance corrosion resistance in harsh conditions (e.g., outdoor, humid, or chemical-exposed environments). HDG conforming to EN ISO 1461.

Design: Engineered with reinforced structural supports (e.g., welded ribs or bolted plates) to withstand high-impact forces.

engineered, supplied and installed by Sinchold for Saudi Aramco at MYP, KSA

Impact Absorption: Designed to dissipate kinetic energy during collisions, minimizing damage to both the crane and rail system.

Modular Compatibility: Configurable to match standard crane rail profiles (e.g., DIN536-1 A65, A75, A100, A150, or custom specifications).

Easy Installation: Pre-drilled base plates for secure anchoring to concrete foundations or steel substrates using high-tensile bolts.

Low Maintenance: Weather-resistant materials reduce long-term wear.

Industrial Cranes: Gantry cranes, overhead cranes, and jib cranes in factories, warehouses, refineries, steel mills and shipyards etc.

Ports & Logistics: Container handling equipment and rail-mounted transfer systems.

Mining & Heavy Industry: Robust protection for high-capacity crane systems.

Conforms to ISO 9001 for quality management and FEM/DIN standards for load-bearing capacity.

Optional non-sparking designs (e.g., aluminum-bronze alloy) for explosive environments (ATEX compliance).

Height, width, and energy-absorption capacity tailored to rail type and crane specifications.

Rubber or polyurethane padding for reduced noise and vibration.