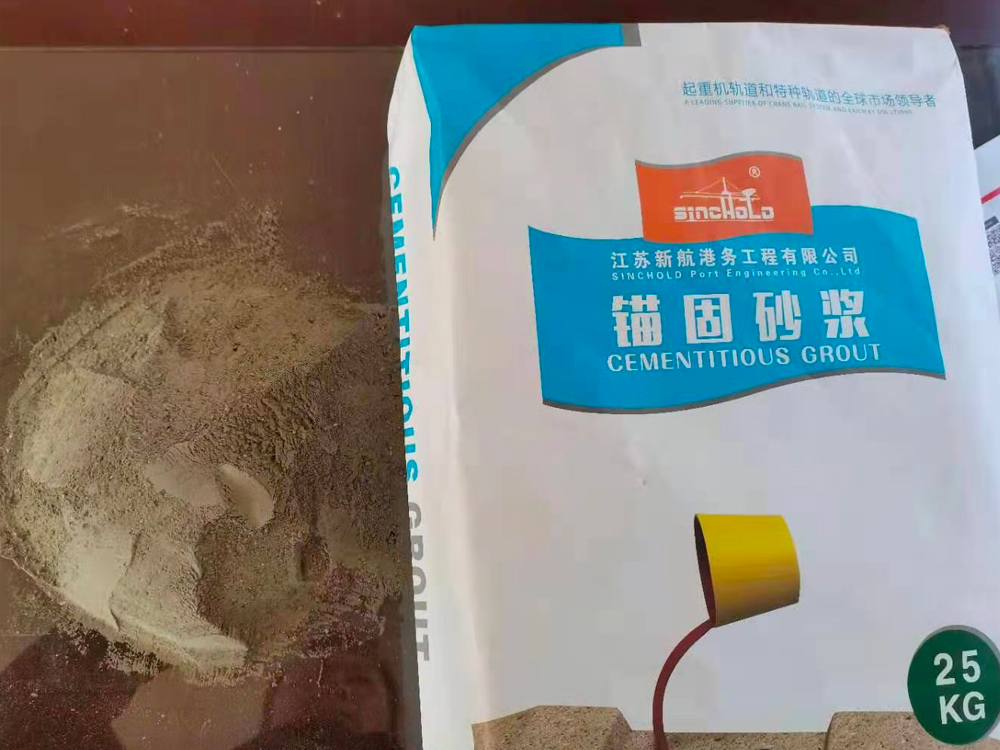

The grout material is manufactured through industrial production using cement-based cementing materials, mineral admixtures, and high-performance additives. By adding water and mixing thoroughly, it can be poured into bolt holes or beneath tracks to ensure uniform load distribution and support various upper forces. This enhances durability, shortens construction timelines, and reduces environmental pollution in applications such as ports, docks, and high-speed railways.

● Rail Groove Grouting: Ideal for grouting rail groove of port and wharf cranes, as well as rail clamp/clip grouting, base plate leveling, and bolt fixing.

● Equipment Grouting: Suitable for primary and secondary grouting of various mechanical and electrical equipment, including heavy machinery and high-precision grinding machines.

(1) Basic Treatment and Formwork:

Scabble the surface of the concrete foundation and clean it. Components that will be bonded together with the base material (such as the steel backing plate) should be cleaned of rust and oil.

Wet the surface of the concrete foundation 4 to 24 hours before pouring the grout, ensuring there is no standing water at the time of pouring.

The formwork must be strictly supported to prevent leakage.

(2) Curing:

1.Cover the poured material with a wet straw bag or cloth, and perform watering maintenance 2 to 6 times a day.

2.The curing temperature should be above 15°C, with a curing period of 7 days. If the site temperature is low, the curing period can be extended appropriately.

3.Winter construction requires insulation measures.

4.Formwork removal should be carried out 24 hours after watering, and curing should continue after formwork removal.

(3) Grouting:

Add Water: Add water at a ratio of 3.5 kg per bag (25 kg) and mix. If the construction does not require greater mobility, the water consumption can be reduced accordingly.

Mixing Procedure: Add the specified amount of water into the mixing bucket, then add part of the dry material into the bucket and start mixing. After that, pour the remaining material into the bucket and continue mixing. The total mixing time from start to finish should be controlled to about 3 to 5 minutes.

During Mixing: Move the mixing paddle slowly around the perimeter of the barrel to ensure that dry materials adhering to the bottom and sides (wall) of the barrel are thoroughly mixed. The mixing paddle should not be lifted above the liquid level of the mixture to prevent air from entering the mixture.

Pouring Process: Pour the mixture from one side as much as possible to facilitate the expulsion of air between the base plate and the concrete foundation. If necessary, tools such as bamboo sticks can be used to guide the flow. Once started, the pouring process must be carried out continuously without interruption.