Top Heavy Haul Rail Fasteners: Best OEM Manufacturers & Factory Solutions

When it comes to Heavy Haul Rail Fasteners, quality and reliability are essential. As a trusted supplier, I focus on providing durable and efficient components that can withstand the demands of heavy transportation. Our fasteners are engineered for performance, ensuring safety and stability on each journey. By collaborating directly with factories, I guarantee the use of top-grade materials and advanced manufacturing processes to enhance the longevity of our products. Whether upgrading existing rail systems or starting new projects, my Heavy Haul Rail Fasteners offer the strength you need. Partnering with SINCHOLD Co., Ltd. means choosing an industry leader dedicated to delivering superior solutions tailored to your requirements. Together, we can strengthen your operations with fasteners designed for lasting success.

Trending Heavy Haul Rail Fasteners Factory-Direct Excellence Delivers Unmatched Quality

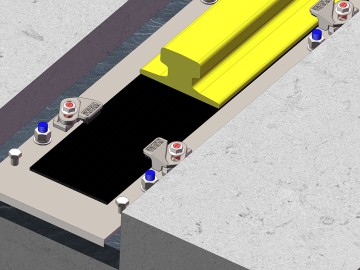

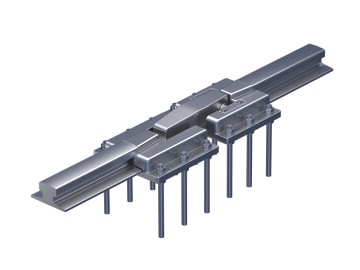

In the world of heavy haul rail transportation, the need for high-quality rail fasteners has never been more critical. The right fasteners ensure the safety, efficiency, and longevity of railway systems, directly impacting operational success. Today, innovative manufacturers are stepping up to deliver factory-direct excellence, providing products that meet stringent industry standards while also catering to the varied requirements of global procurement. By focusing on engineering, production, installation, and technical service, these manufacturers offer a comprehensive solution that enhances the reliability of railway infrastructure.

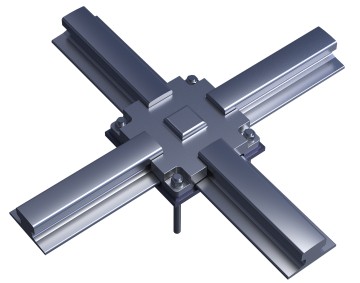

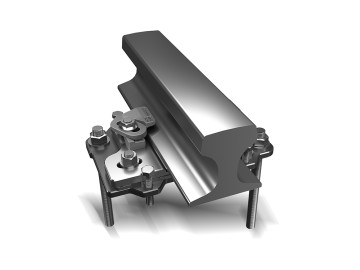

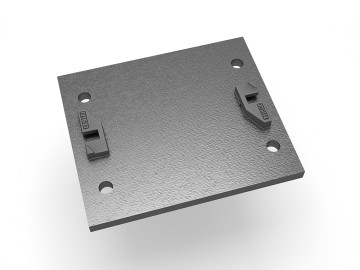

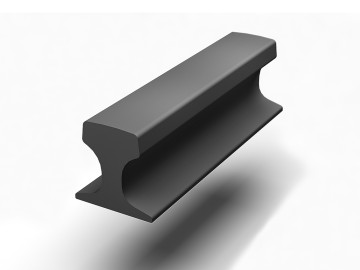

The railway e-clip series and turnout systems have set the benchmark for performance and durability. These specialized fasteners are designed to withstand the rigors of heavy loads and frequent use, making them an ideal choice for a range of applications. Whether it's maintaining track stability or facilitating smooth transitions at turnouts, the quality and precision of these products are unmatched in the industry. Businesses looking to optimize their rail operations should prioritize sourcing from manufacturers that emphasize integrated production and technical support, thereby ensuring that they receive not just products, but also expertise and ongoing service.

Moreover, the combined series of fastening systems represents a significant advancement in the rail fastening landscape. By integrating various components into a cohesive system, these solutions allow for easier installation and enhanced performance. Global purchasers can benefit from the innovative designs and high-grade materials that are engineered for superior resistance against wear and environmental factors. As the demand for efficient transportation solutions continues to rise, aligning with manufacturers that prioritize excellence in their rail fastening systems will be key to achieving operational goals and maintaining a competitive edge in the market.

Trending Heavy Haul Rail Fasteners Factory-Direct Excellence Delivers Unmatched Quality

| Fastener Type | Material | Size (mm) | Weight (kg) | Load Capacity (t) | Price (USD) |

|---|---|---|---|---|---|

| Rail Clip | Carbon Steel | 100 | 0.5 | 30 | 15 |

| Bolt | Stainless Steel | 80 | 0.3 | 25 | 20 |

| Washer | Aluminum | 50 | 0.1 | 10 | 5 |

| Rail Bumper | Composite Material | 120 | 2.0 | 50 | 45 |

| Sleeper Screw | High Strength Steel | 70 | 0.4 | 15 | 10 |

Key Methods For Heavy Haul Rail Fasteners Application Manufacturer

E

Ethan Johnson

The response time from customer support was fantastic. They really know their products well.

09

May

2025

J

Jackson Collins

Fantastic support! They helped me with a tricky issue and were very patient.

07

May

2025

L

Layla Allen

This product is definitely worth the investment. Quality like this is hard to find.

08

May

2025

W

William Brown

I can’t recommend this product enough. The after-sales staff were not only professional but also genuinely interested in helping solve my concerns.

14

May

2025

M

Matthew Wright

I’m very pleased with my purchase! The after-sales service was prompt and very professional, a rare find these days.

16

June

2025

D

Daniel Miller

Quality is outstanding, and the team behind it is equally impressive. They addressed my concerns with utmost professionalism.

15

June

2025