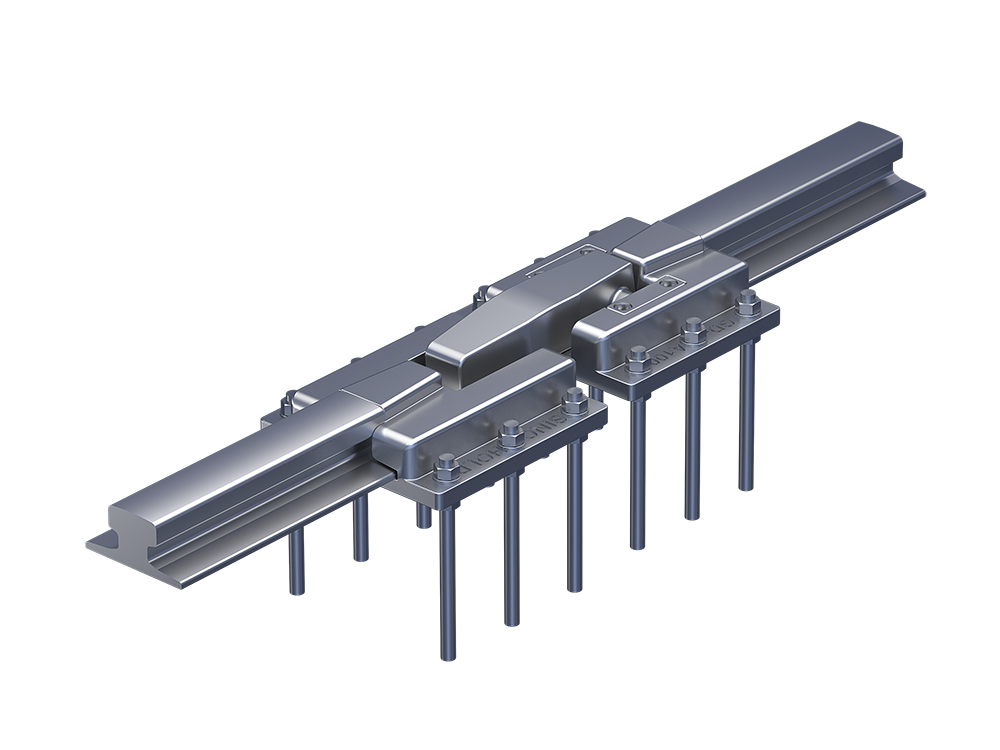

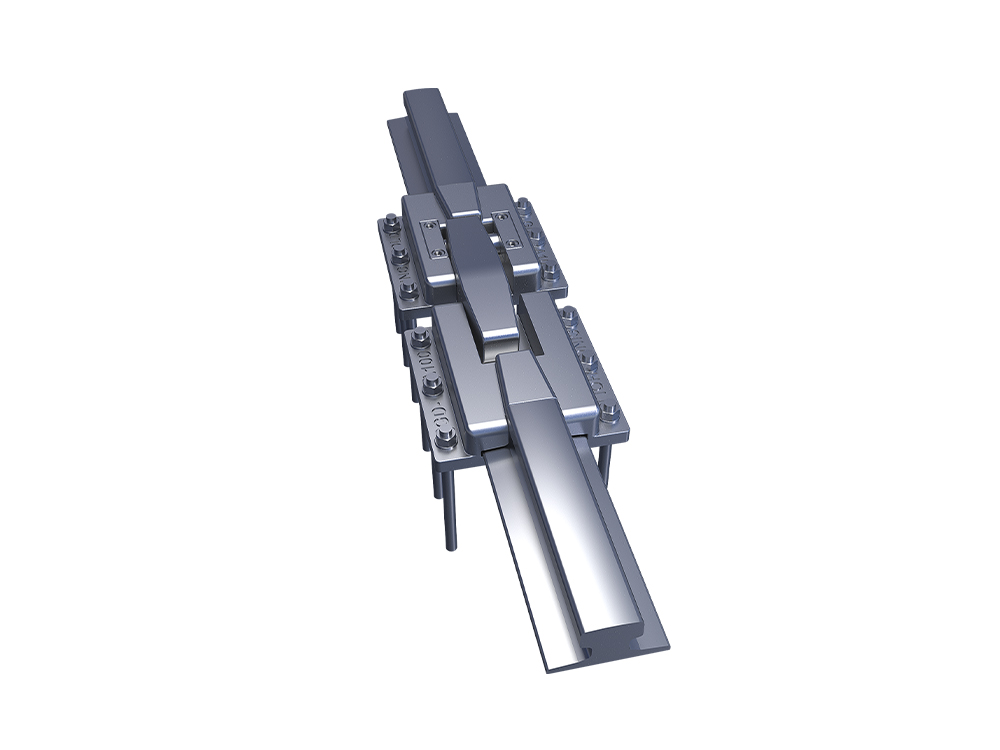

Modular Transition Track System (MTTS)

SINCHOLD has secured a patent for the Modular Transition Track System (MTTS) designed for the dock expansion joints, reinforcing its commitment to serving global clients with cutting-edge solutions. The system has already been successfully deployed in the Middle East market, where extreme day-night temperature variations pose significant challenges to rail systems. The practicality and reliability of SINCHOLD's modular transition track system (MTTS) have been thoroughly validated in these demanding conditions.

In Saudi Arabia, SINCHOLD Modular Transition Rail System has earned strong recognition from Aramco, providing new operational support for the oil giant. Moving forward, SINCHOLD remains dedicated to solving industrial challenges worldwide, delivering superior design concepts to global customers.

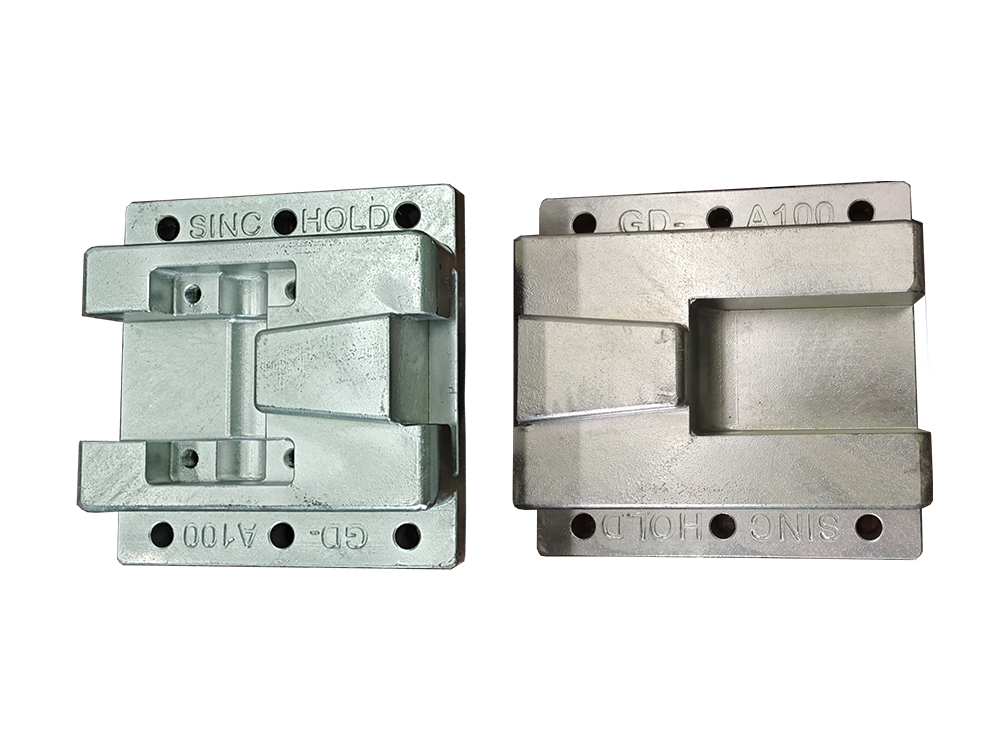

Material Selection

High-strength, wear-resistant, and corrosion-resistant steel is selected, specifically 42CrMo alloy.

Cutting & Blanking

Raw materials are precision-cut to specified dimensions using specialized cutting equipment.

Forming & Machining

CNC milling machines shape the cut materials to exact design specifications.

Heat Treatment

Components undergo quenching and tempering processes to enhance mechanical properties.

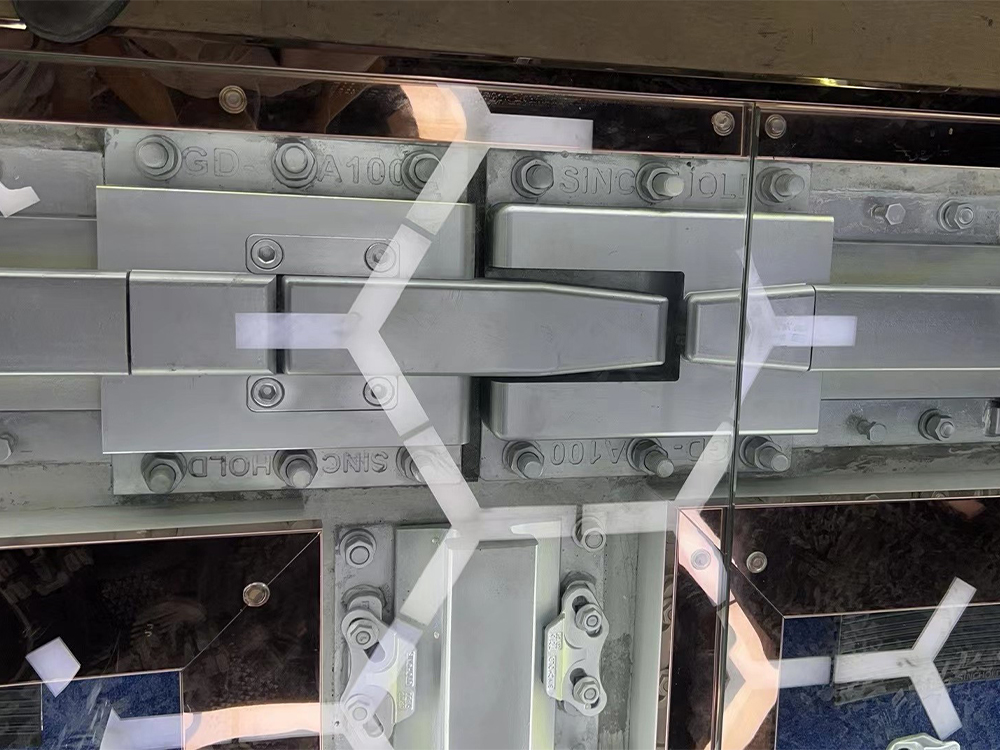

engineered, supplied and installed by Sinchold for the Maritime Yard, Saudi Aramco

engineered, supplied and installed by Sinchold for the Maritime Yard, Saudi Aramco

Surface Treatment

All parts receive hot-dip galvanization for superior corrosion protection.

Assembly

Components are meticulously assembled into a complete transition module assembly per design requirements.

Inspection & Testing

Rigorous quality checks and performance tests ensure compliance with all mechanical and operational standards.

Packaging & Shipping

Approved products are properly packaged and prepared for delivery to customers.