Optimizing Network Rail Maintenance: ODM Solutions for Factories and Suppliers

In the realm of Network Rail Maintenance, SINCHOLD Co., Ltd. stands out as a trusted partner for wholesale solutions. We specialize in delivering high-quality products specifically designed for the rail industry's manufacturers and suppliers. Our comprehensive selection of maintenance tools and equipment adheres to the highest standards, ensuring optimal functionality and safety. With a focus on clear communication and punctual delivery, we help keep your projects on schedule. Our dedicated team works closely with you to understand your unique needs and offers tailored support throughout the process. With SINCHOLD Co., Ltd., you gain a dependable partner committed to improving your operations and addressing your Network Rail Maintenance requirements with exceptional quality and service.

Practical Strategies for Network Rail Maintenance Your Trusted OEM Partner Your End-to-End Solution

In the ever-evolving landscape of rail transportation, maintaining the integrity and efficiency of rail infrastructure is paramount. Practical strategies for network rail maintenance can significantly enhance operational reliability and safety. Collaborating with trusted Original Equipment Manufacturers (OEMs) can streamline the maintenance process, ensuring that quality components are readily available and that service is efficient and dependable. By partnering with an established OEM, procurement professionals can ensure they are not only meeting current demands but are also prepared for future challenges.

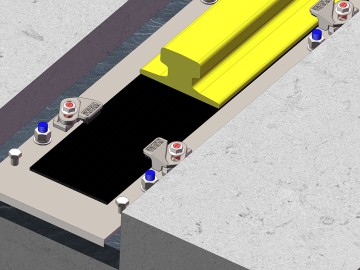

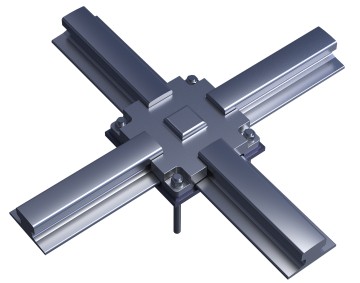

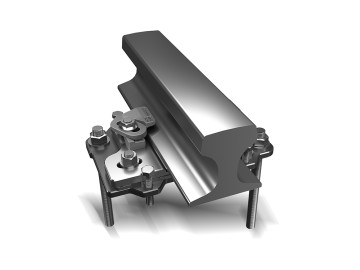

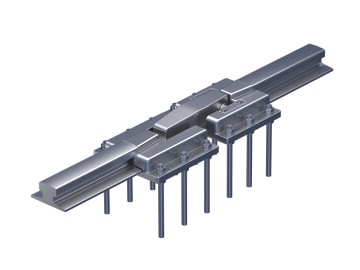

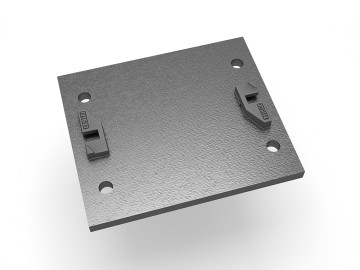

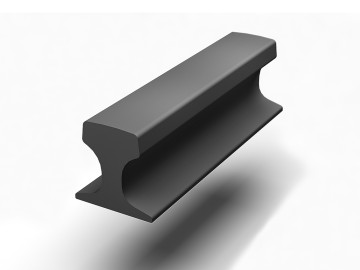

Comprehensive solutions for rail fasteners and accessories can optimize network maintenance strategies. Specialized products, including innovative e-clips and advanced turnout systems, are designed to withstand the rigors of rail operations while providing safe and secure fastening solutions. These components are engineered with precision to ensure longevity and minimal maintenance requirements, allowing for smoother operations and reduced downtime. Additionally, an integrated approach that combines engineering, production, installation, and technical support enables seamless coordination throughout the maintenance cycle, enhancing overall performance and cost-effectiveness.

Ultimately, a commitment to excellence in network rail maintenance requires a holistic strategy that incorporates high-quality products and services. By leveraging the expertise of dedicated OEM partners, procurement managers can secure reliable materials and support that ensure the safety and efficiency of rail networks worldwide. This partnership not only facilitates the smooth operation of existing systems but also paves the way for sustainable growth in the rail industry.

Practical Strategies for Network Rail Maintenance

| Strategy | Description | Benefits | Implementation Timeline |

|---|---|---|---|

| Predictive Maintenance | Utilizing sensor data and analytics to predict failures before they occur. | Reduces unplanned downtime, increases asset life. | 3-6 months |

| Regular Training Programs | Continuous education and training for maintenance staff on best practices. | Enhances skill sets, improves safety and efficiency. | Ongoing |

| Inventory Optimization | Streamlining inventory management to reduce excess stock and costs. | Cost savings, improved resource availability. | 2-4 months |

| Collaborative Partnerships | Working closely with OEMs for better access to technology and support. | Improved technology access, better problem resolution. | 1-2 months |

| Digital Transformation | Implementing digital tools for scheduling, tracking, and reporting. | Increases efficiency, provides real-time data insights. | 6-12 months |

Best Brands For Network Rail Maintenance Supplier Dominates

G

Grace Liu

I highly recommend this product for its premium quality. The support team was not only polite but also very efficient.

25

June

2025

A

Anthony Miller

Top-quality materials used in this product! The dedication and expertise of the support staff really stood out.

06

July

2025

I

Isaac King

The quality really stands out. I’m grateful for the professional customer support that enhanced my shopping experience.

02

June

2025

M

Maria Lopez

The after-sales service was top-notch. The team went above and beyond to ensure I was satisfied.

29

June

2025

A

Avery Murphy

The product is a game changer! Its quality makes my work so much easier.

14

June

2025

M

Mason Parker

Support was exceptionally helpful! Their professionalism made a huge difference.

21

May

2025