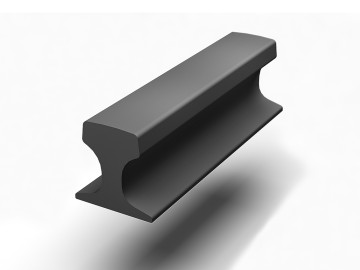

Premium Wholesale Rail Sections from Top Manufacturers and Factories

At SINCHOLD Co., Ltd., we excel in providing top-quality rail sections designed specifically for OEMs and manufacturers across various industries. Our state-of-the-art production techniques ensure that each rail section adheres to the highest standards necessary for your projects. Understanding the needs of our clients, we prioritize both durability and precision in our offerings. Our rail sections undergo thorough testing and inspection to guarantee consistent quality and reliable delivery. Our dedicated team is ready to offer technical support and customization options to perfectly align our products with your specific requirements. Choose SINCHOLD for your rail section needs and experience the benefits of partnering with a trusted manufacturer. Together, we can enhance your operations with our exceptional products.Key Methods For Rail Sections From Concept to Delivery Stands Out

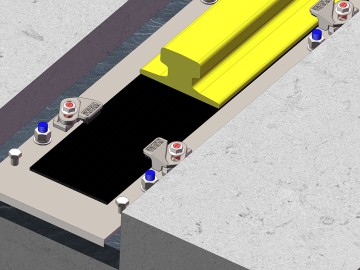

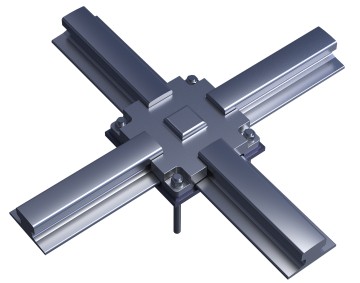

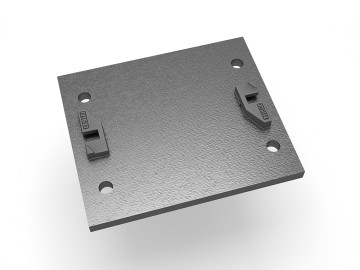

SINCHOLD stands out as a leading integrated manufacturer dedicated to providing innovative solutions for rail sections, from concept to delivery. Our expertise in engineering, production, installation, and technical service ensures that we meet the diverse needs of global procurement professionals looking for reliable rail fasteners and accessories. Our flagship products include the railway e-clip series and turnout series, which are designed for safety and efficiency in rail operations.

Our comprehensive approach allows us to customize our fastening systems to fit various railway infrastructures. We understand that every project has unique requirements, and our technical service team collaborates closely with clients to ensure that the solutions we provide not only meet industry standards but also enhance operational performance. By choosing SINCHOLD, clients benefit from a partner committed to quality, innovation, and comprehensive support throughout the entire manufacturing and installation process.

In an industry where timely delivery and reliability are paramount, SINCHOLD’s robust production capabilities and logistical efficiency ensure that we stand out in the global market. Whether you are managing a large-scale rail project or seeking specialized components, our dedicated team is ready to assist you in making your vision a reality, solidifying our position as a trusted name in railway solutions.

Key Methods For Rail Sections From Concept to Delivery Stands Out

| Method | Description | Advantages | Challenges |

|---|---|---|---|

| Computer-Aided Design (CAD) | Utilizing software for detailed rail section design. | Increases precision and reduces errors. | Requires training and software costs. |

| Finite Element Analysis (FEA) | Simulation of physical stresses on rail sections. | Identifies potential failure points early. | Computationally intensive and time-consuming. |

| 3D Printing Prototypes | Creating physical models of rail sections for testing. | Cost-effective for small production runs. | Limited materials and durability of prints. |

| Integrated Project Delivery (IPD) | Collaborative approach involving all stakeholders from start to finish. | Improves communication and resource management. | Requires trust and commitment from all parties. |

| Lean Manufacturing Principles | Focusing on minimizing waste and maximizing value. | Reduces costs and speeds up delivery. | Requires cultural shift and training. |

Comprehensive Comparison of Rail Sections Your Trusted OEM Partner Manufacturer

S

Samuel Hill

Absolutely impressed with the quality. The after-sales support has shown remarkable professionalism!

04

July

2025

B

Benjamin Perez

Quality exceeds expectations. The customer support team provided exceptional service—very professional.

23

June

2025

E

Ella Rodriguez

Incredible quality! The after-sales team was extremely helpful and knowledgeable.

19

June

2025

E

Ethan Johnson

The response time from customer support was fantastic. They really know their products well.

09

May

2025

A

Amelia Robinson

Absolutely love this product! The quality is superb and well worth the price.

05

June

2025

L

Lila Cooper

Beautifully crafted product! The quality is evident in every detail.

27

May

2025