Top ODM Manufacturers for Reliable Railway Track Replacement Solutions

At SINCHOLD Co., Ltd., we are dedicated to providing exceptional railway track replacement solutions that cater to the specific needs of our clients. Specializing in ODM services, we manufacture high-quality components that meet stringent industry standards. Our advanced factories, equipped with cutting-edge machinery and experienced professionals, ensure precision in every product. With a strong background in the railway sector, we adapt quickly to evolving demands and maintain competitive pricing without sacrificing quality. Choosing to collaborate with us guarantees access to an efficient supply chain, prompt delivery, and reliable customer support. Whether serving small contractors or large rail corporations, we aim to facilitate a smooth and effective procurement process, ensuring your railway infrastructure meets operational needs with reliability.Proven Methods To Railway Track Replacement Products For the Current Year

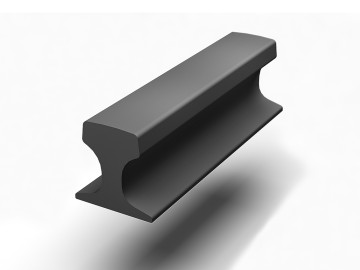

In the ever-evolving landscape of railway infrastructure, the need for reliable and efficient track replacement products has become paramount. As we progress through the current year, it is essential for global procurement professionals to focus on proven methods that ensure longevity, safety, and cost-effectiveness in railway track maintenance. One of the key components of this process is selecting high-quality rail fasteners and accessories, which play a crucial role in sustaining the integrity of the entire railway system.

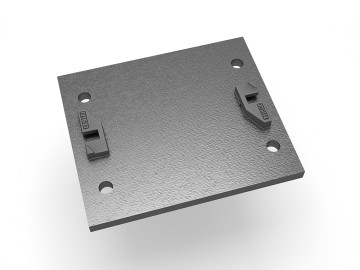

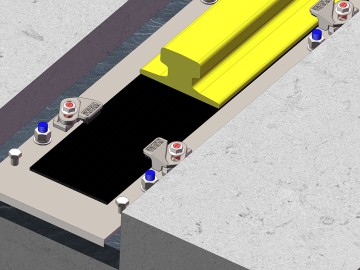

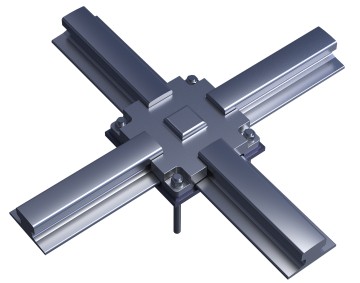

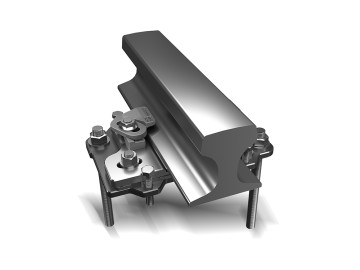

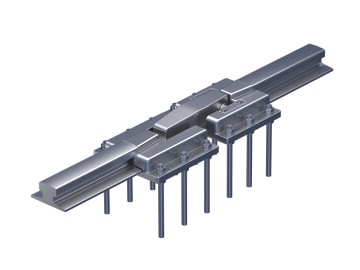

Among the most advanced solutions available today are the railway e-clip series and turnout series. These products are engineered to withstand the rigorous demands of heavy train loads and harsh environmental conditions, thereby minimizing the frequency of replacements and repairs. Integrating advanced manufacturing techniques, these fasteners offer superior durability and stability, which are essential for seamless train operations. Furthermore, the combined fastening system of railway tracks not only enhances the overall performance but also streamlines installation processes, reducing downtime and associated costs.

To remain competitive in the global market, procurement professionals must prioritize partnerships with manufacturers who are committed to innovation and technological advancement in their offerings. By focusing on high-performance and reliable track replacement products, stakeholders in the railway industry can ensure safer, more efficient transportation and foster long-term sustainability in their operations. As we navigate the complexities of this sector, embracing these proven methods will undoubtedly pave the way for future success.

Proven Methods To Railway Track Replacement Products For the Current Year

| Method | Materials Used | Maintenance Frequency | Cost Efficiency | Estimated Lifespan |

|---|---|---|---|---|

| Traditional Replacement | Steel Rails, Wooden Sleepers | 2-5 years | Moderate | 30 years |

| Boltless Track System | Steel Rails, Composite Sleepers | 3-7 years | High | 50 years |

| Concrete Sleeper Replacement | Concrete Rails, Concrete Sleepers | 1-3 years | High | 40 years |

| Advanced Sleeper Replacement | Steel Rails, Polymer Sleepers | 5-10 years | Very High | 60 years |

| Resurfacing Technique | Elastomeric Material | 6 months - 1 year | Low | 10 years |

Discovering Railway Track Replacement Factory Winning in 2025

M

Matthew Wilson

Lovely product with superior quality. I was very impressed by the professionalism of the support team.

27

June

2025

A

Avery Roberts

Great product and outstanding after-sales assistance! The staff was knowledgeable and eager to help.

11

May

2025

L

Lucas Evans

Beyond satisfied with the quality. Professional support staff made the whole process seamless.

19

May

2025

J

James Anderson

The product quality exceeded my expectations. It performs flawlessly, and I’m impressed by the attention to detail.

04

July

2025

G

Grace Martinez

Very pleased with my purchase! The quality really speaks volumes about the brand.

22

May

2025

O

Oliver Robinson

The dedication to customer service is evident. They made my experience truly enjoyable.

29

May

2025