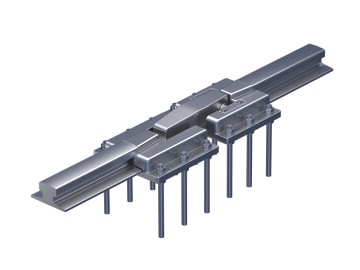

Custom Shipyard Crane Track Manufacturer & Supplier - Reliable Solutions for Your Needs

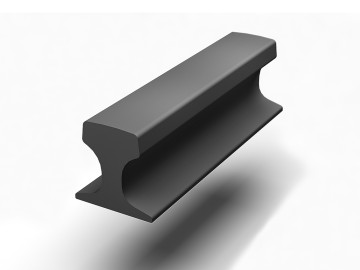

Our high-quality shipyard crane tracks are meticulously designed and manufactured in China to meet the demanding needs of heavy operations. Crafted for exceptional reliability and efficiency, these tracks ensure seamless movement and robust support for heavy lifting equipment, prioritizing safety and productivity at every stage. Choosing SINCHOLD Co., Ltd. means partnering with a trusted leader in the industry, renowned for our commitment to quality and customer satisfaction. Our dedicated team is always available to assist you, making the purchasing experience straightforward and efficient. With our shipyard crane tracks, you gain a dependable ally for all your heavy lifting requirements. Elevate your operations with our unmatched expertise and dedication to excellence.Best Methods To Shipyard Crane Track Where Service Meets Innovation Your End-to-End Solution

In the rapidly evolving landscape of the manufacturing sector, where efficiency and reliability are paramount, SINCHOLD stands out as a beacon of innovation in the production of rail fasteners and accessories. As an integrated manufacturer, we specialize in engineering, production, installation, and technical service, ensuring that every aspect of our product lifecycle is designed to meet the rigorous demands of modern transportation infrastructure. Our offerings include a comprehensive range of solutions, such as the railway e-clip series and railway turnout series, tailored to enhance the performance and durability of your projects.

What sets SINCHOLD apart is our commitment to merging service with cutting-edge innovation. We understand that our global clients are not just looking for products; they seek end-to-end solutions that streamline operations and minimize downtime. Our dedicated team of experts works closely with customers to provide tailored support, ensuring seamless installation and maintenance. With our combined fastening system of railway track, we offer not just components, but a holistic approach that optimizes supply chains and elevates operational excellence.

Choosing SINCHOLD means partnering with a forward-thinking manufacturer that prioritizes quality and service, ultimately empowering your projects to thrive in an increasingly competitive market. Experience the difference where service meets innovation; let us be your reliable partner in navigating the complexities of rail transportation.

Best Methods To Shipyard Crane Track Where Service Meets Innovation Your End-to-End Solution

| Method | Description | Advantages | Considerations |

|---|---|---|---|

| Laser Scanning | Utilizing laser technology for precise measurements of crane tracks. | High accuracy, quick data capture, and reduced human error. | Initial costs can be high; requires trained personnel. |

| Drones | Using drones equipped with cameras to inspect crane tracks from the air. | Access hard-to-reach areas, fast inspection process. | Weather dependent, licensing may be required for operation. |

| Robotic Inspections | Deploying robotic systems to gather data on crane track conditions. | Can operate in hazardous environments, thorough inspections. | High upfront investment, requires maintenance. |

| Predictive Maintenance Software | Using software to analyze data from crane operations and predict maintenance needs. | Reduced downtime, data-driven decisions. | Requires data collection and interpretation; software costs. |

| Regular Training Programs | Training for operators and maintenance teams on best practices. | Enhanced safety, improved operational efficiency. | Ongoing commitment needed, potential for training fatigue. |

Trending Shipyard Crane Track Now Trending For the Current Year

L

Luna Reed

Absolutely fantastic quality! The after-sales service team was efficient and professional.

30

May

2025

J

James White

The support staff was phenomenal. They provided detailed answers and made me feel very comfortable.

18

May

2025

S

Scarlett King

Incredible quality! You can tell this company takes pride in what they produce.

08

June

2025

D

Daniel Reed

The support team displayed exemplary professionalism, making my buying experience smooth and easy.

27

June

2025

S

Sarah Johnson

The product exceeded my expectations in both performance and durability. I had a small query, and the support staff handled it with genuine care and professionalism.

08

May

2025

C

Christopher Taylor

Impressive product quality! The customer service team was very professional and went above and beyond to assist me.

30

May

2025