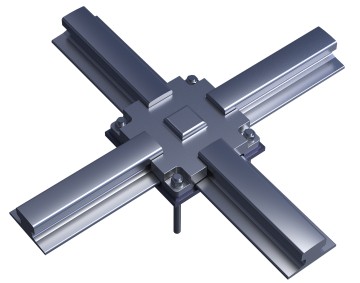

Quality Spherical Bearing Tie-Backs from Trusted Suppliers and Factories

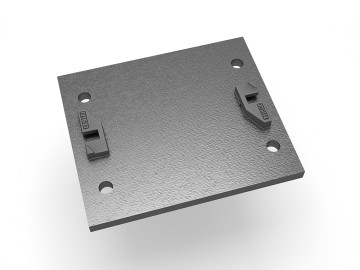

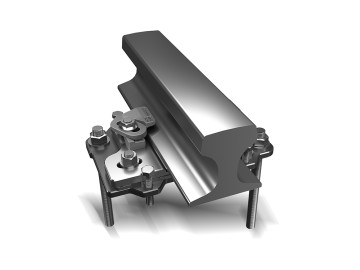

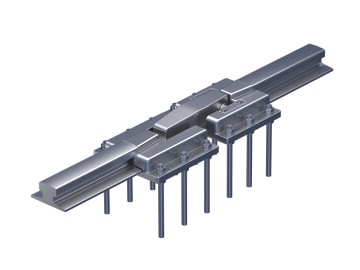

Reliable Spherical Bearing Tie-Backs play a crucial role in ensuring the quality and durability of your projects. As a seasoned manufacturer, I am dedicated to delivering ODM solutions designed specifically for your requirements. Our Spherical Bearing Tie-Backs are meticulously engineered to withstand high loads and extreme conditions, guaranteeing both safety and performance. With SINCHOLD Co., Ltd., you have a trusted partner for these specialized components. Each product is held to stringent quality standards, providing you with confidence in your purchase. We collaborate closely with clients to create customized designs tailored to unique applications. Partnering with us means you benefit from innovative solutions and a steadfast commitment to exceptional service. Elevate your projects with our top-tier Spherical Bearing Tie-Backs, designed for strength and long-lasting reliability.

How To Decide Between Spherical Bearing Tie-Backs Application For the Current Year

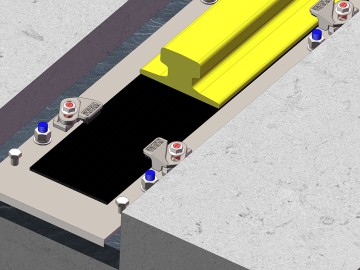

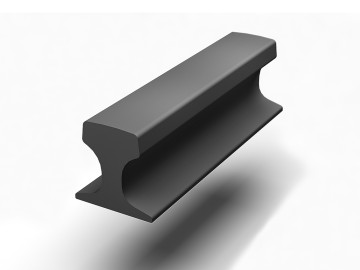

When considering the application of spherical bearing tie-backs in the current year, procurement professionals face a critical decision that impacts both performance and longevity of railway systems. Spherical bearings provide enhanced flexibility and load distribution, making them ideal for dynamic rail environments. In this context, evaluating the specific needs of your project becomes paramount. Factors such as load capacities, environmental conditions, and maintenance routines play crucial roles in determining the suitability of spherical bearings for your railway applications.

Moreover, understanding the broader range of fastening systems available is essential. Integrating tie-backs with advanced rail fasteners can enhance track stability and reduce wear on components. The choice of materials and design can also significantly influence the durability and reliability of the entire system. As you navigate procurement, collaborating with manufacturers that specialize in end-to-end solutions—ranging from initial engineering and production to installation and technical support—will ensure that you are equipped with the best products tailored to your specific application needs.

Finally, staying informed about the latest industry trends, technological advancements, and regulatory changes is crucial for making informed decisions. Engaging with technical experts in the field can provide valuable insights into best practices and novel applications of spherical bearings. By carefully weighing your options and leveraging the expertise of industry specialists, you will be better positioned to enhance the performance and safety of your railway networks in the year ahead.

How To Decide Between Spherical Bearing Tie-Backs Application For the Current Year

| Application Type | Load Capacity (kN) | Installation Depth (m) | Cost Estimate ($) | Preferred Material | Applications |

|---|---|---|---|---|---|

| Standard Spherical Bearing | 120 | 5 | 1500 | Steel | Retaining walls, Foundations |

| High-Load Spherical Bearing | 200 | 7 | 2500 | Stainless Steel | Heavy structures, Bridges |

| Corrosion Resistant Spherical Bearing | 150 | 6 | 1800 | Coated Steel | Marine applications, Chemical plants |

| Lightweight Spherical Bearing | 80 | 4 | 900 | Aluminum | Temporary structures, Light loads |

| Shock Absorbing Spherical Bearing | 130 | 5.5 | 2000 | Rubber/Metal Composite | Seismic applications, Vibration control |

How To Evaluate Spherical Bearing Tie-Backs Where Service Meets Innovation Is The Best

A

Anthony Miller

Top-quality materials used in this product! The dedication and expertise of the support staff really stood out.

06

July

2025

W

Wyatt Campbell

A truly exceptional product! The expertise and professionalism of the after-sales staff stood out.

13

June

2025

L

Lucas Evans

Beyond satisfied with the quality. Professional support staff made the whole process seamless.

19

May

2025

M

Maria Lopez

The after-sales service was top-notch. The team went above and beyond to ensure I was satisfied.

29

June

2025

D

Daniel Nelson

Service after the sale is crucial, and this team nailed it! Very professional and attentive.

12

May

2025

O

Owen Baker

The professionalism displayed by the service staff was very reassuring. A lovely experience overall.

09

June

2025