Wholesale Steel Mills Crane Runway Solutions – Top Supplier & Manufacturer Services

When considering Steel Mills Crane Runways, high-quality solutions that endure the rigors of heavy industrial environments are essential. Our products not only meet but exceed industry standards, emphasizing durability and performance in every aspect. We recognize the unique challenges faced by B2B purchasers, from safety concerns to efficiency optimization. That's why our Steel Mills Crane Runways are meticulously engineered for longevity, ensuring reliable operations in your steel mill. Partnering with SINCHOLD Co., Ltd. provides access to expert support and customized solutions tailored to your specific needs. Rely on our commitment to quality and responsive service to enhance your operational capabilities.Best Practices For Steel Mills Crane Runway Leads the Global Market Supplies the World’s Top Brands

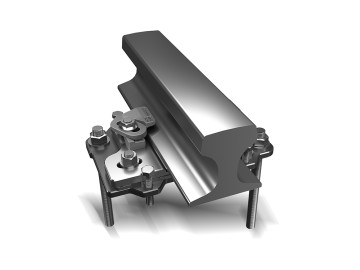

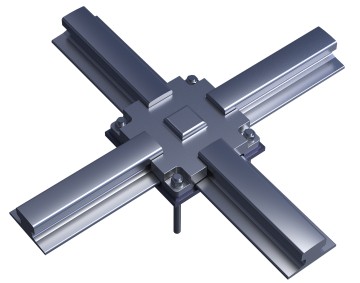

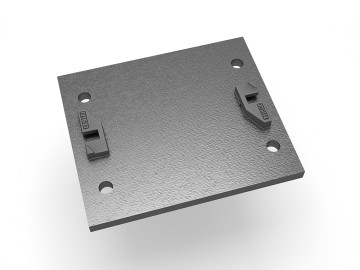

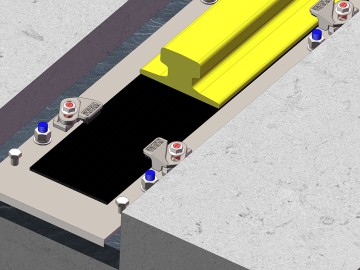

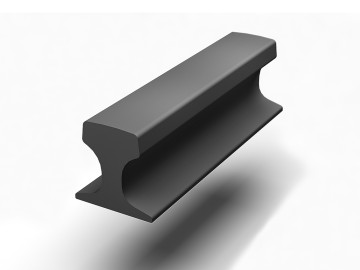

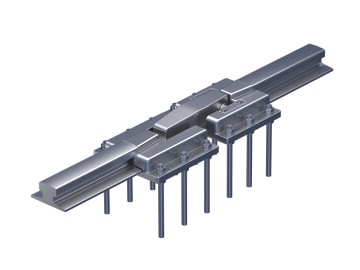

In the competitive landscape of industrial manufacturing, steel mills are critical to the infrastructure that supports global economies. One essential component often overlooked is the crane runway systems that facilitate the movement of heavy materials within these facilities. Implementing best practices in crane runway design and installation is crucial to ensuring safety, maximizing efficiency, and extending the lifespan of equipment. By focusing on the integration of high-quality rail fasteners and accessories, steel mills can optimize their operations and enhance productivity.

The reliability of crane systems directly impacts the operational capacity of steel mills. Using superior rail fasteners and innovative fastening systems ensures that cranes operate smoothly and safely under heavy load conditions. Regular maintenance and updates to these systems, informed by the latest engineering standards, will further bolster performance. Industries seeking to improve their operational efficiency must invest in advanced fastening solutions that cater specifically to the demanding environments of steel mills, ensuring compatibility with existing railway systems and contributing to overall productivity.

Moreover, collaboration with experienced manufacturers who offer a comprehensive range of products and technical support can provide a competitive edge. As global demand for high-quality steel continues to rise, adopting best practices for crane runway systems not only enhances operational efficiency but also positions steel mills favorably within the market, making them more attractive to leading brands in need of reliable supply chains. Emphasizing the significance of innovative fastening solutions will be paramount in meeting the increasing needs of the industry, thereby reinforcing the commitment to quality and excellence in production.

Best Practices For Steel Mills Crane Runway Leads the Global Market Supplies the World’s Top Brands

| Dimension | Value | Unit |

|---|---|---|

| Crane Lift Capacity | 50 | ton |

| Runway Length | 200 | meters |

| Runway Width | 30 | meters |

| Steel Grade Used | S355 | N/A |

| Maintenance Frequency | Quarterly | N/A |

| Lifespan | 25 | years |

| Safety Standards | ISO 9001 | N/A |

| Max Speed | 1.5 | m/s |

How To Steel Mills Crane Runway Winning in 2025 Leads the Global Market

C

Chloe Anderson

The quality of this product is outstanding! Customer service was prompt, knowledgeable, and very polite.

26

May

2025

G

Gabriel Turner

Very impressed with the product quality. The professionalism of the support team made a real difference.

18

June

2025

J

James White

The support staff was phenomenal. They provided detailed answers and made me feel very comfortable.

18

May

2025

I

Isaac Scott

Support team was exemplary. They really put the customer first, which is rare these days.

07

June

2025

A

Abigail Young

I’m really impressed with the high-quality design and functionality of this product!

19

June

2025

E

Elizabeth Anderson

I am thoroughly pleased with this product. Their after-sales service was very seasoned and made me feel valued.

29

June

2025