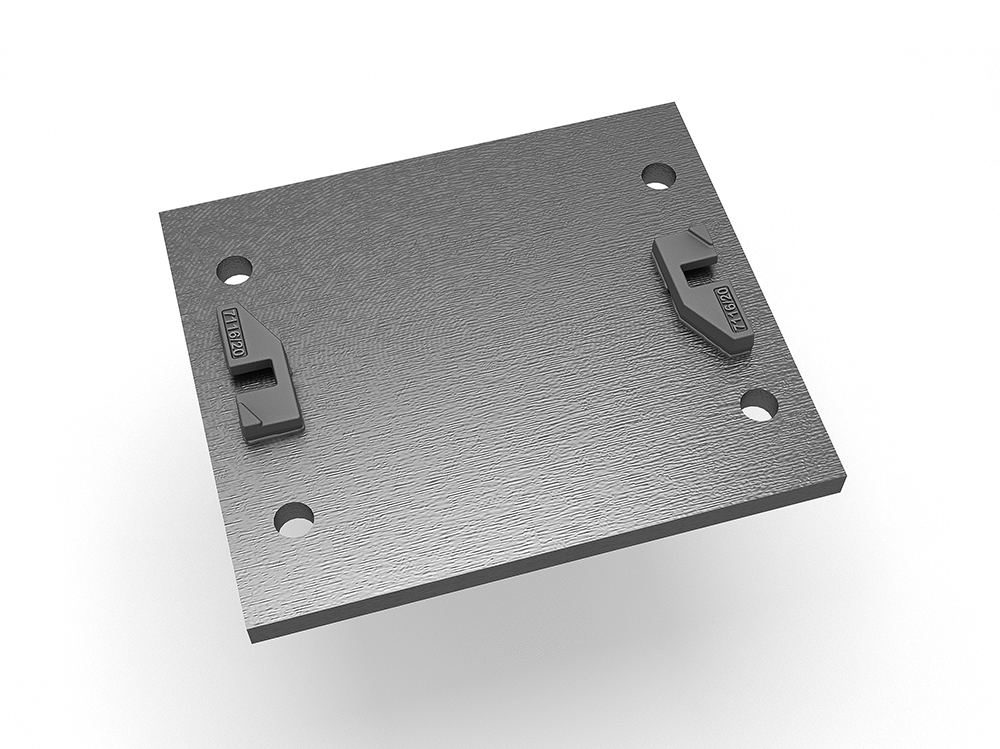

A discontinuous sole plate refers to a steel backing plate that is laid at specific intervals or in a particular layout, rather than continuously.

This method is typically employed in situations requiring precise support points or clearance adjustments, such as:

● Bridges

● Specific sections of building structures

● Machinery components where exact clearance control is essential

Continuous sole plate refers to steel plates that are laid continuously and without interruption, covering a large area or region.

This method is typically used in scenarios requiring extensive support or protection, such as:

● Ground surfaces

● Platforms

● Shelving systems

In these applications, the steel plates help evenly distribute loads and prevent wear.

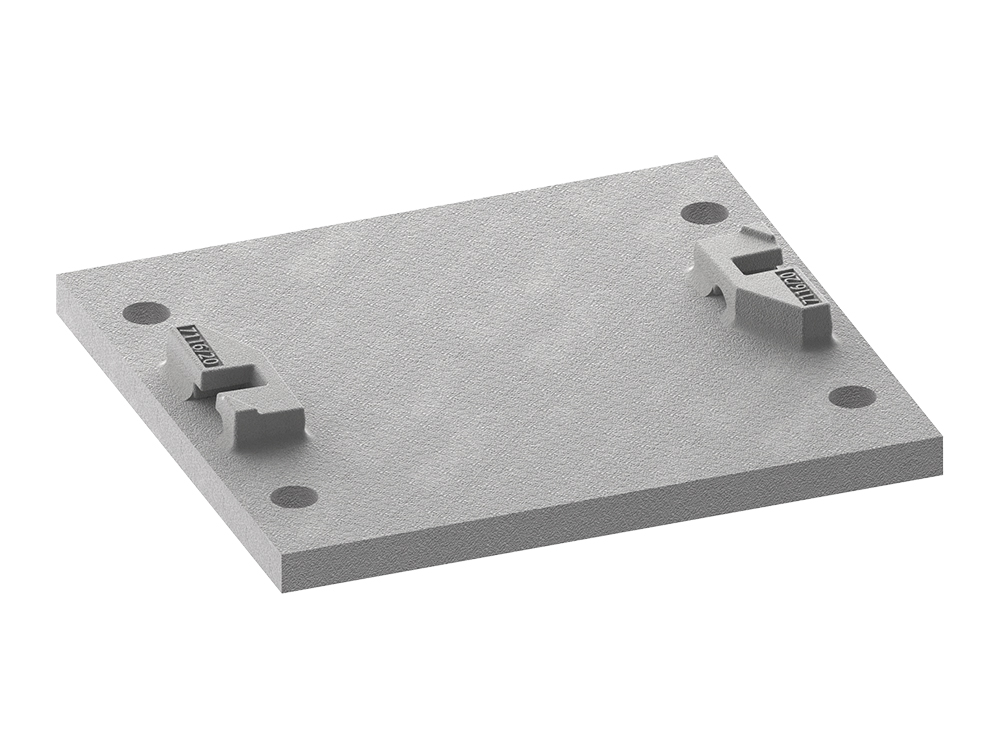

1.High Strength and Stability:

The sole plate is manufactured using high-quality steel as the primary material, providing exceptional strength and stability, capable of withstanding the significant loads and impacts generated by trains during operation.

2.Excellent Cushioning and Shock Absorption:

The inclusion of a rubber layer in the design ensures superior cushioning and shock absorption properties. This effectively reduces the impact and vibrations caused by trains (or cranes) running on the tracks, thereby extending the service life of the track system.

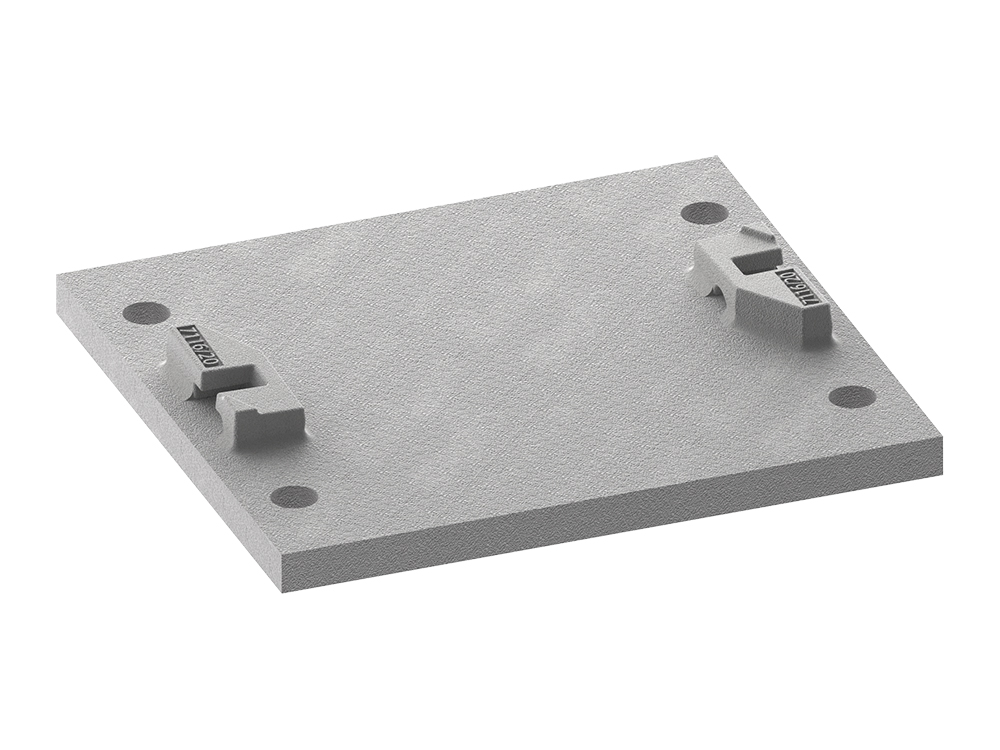

1.Corrosion and Wear Resistance:

The stainless steel sole plate offers excellent corrosion resistance, making it suitable for long-term use in humid, corrosive, and other challenging environments. Additionally, its superior wear resistance ensures durability even under high-intensity conditions.

2.Easy Installation:

The steel plate is designed for simple and quick installation, significantly improving installation efficiency and reducing construction costs.