Top Submerged Arc Welding Rail OEM Manufacturers & Suppliers Guide

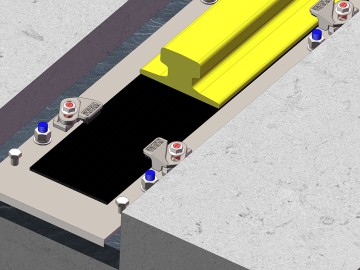

Quality and reliability are essential in Submerged Arc Welding Rails, and at SINCHOLD Co., Ltd., we are dedicated to meeting those needs as a premier manufacturer in China. Our advanced factories combine state-of-the-art technology with skilled craftsmanship to produce rails designed for optimal performance and durability. Understanding the demands of heavy usage in industrial settings, our Submerged Arc Welding Rails are engineered for both precision and strength, making them a top choice for various applications. With a strong commitment to customer satisfaction, we ensure outstanding service and superior products. Partner with us to enhance your welding operations and achieve exceptional results.

How To Evaluate Submerged Arc Welding Rail Where Service Meets Innovation Market Leader

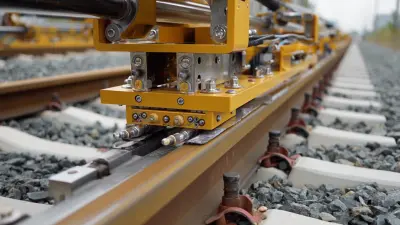

In the ever-evolving landscape of rail infrastructure, the significance of Submerged Arc Welding (SAW) technology cannot be overstated. As global demands for efficient, durable, and cost-effective rail systems increase, evaluating SAW processes in rail manufacturing becomes crucial. The integration of innovation within these welding techniques ensures that the rail fasteners and accessories used in modern railway systems meet stringent safety and performance standards. A meticulous evaluation includes assessing the quality of the welding process, the robustness of the materials used, and the effectiveness of the finished product in real-world conditions.

Innovative approaches in Submerged Arc Welding not only enhance the structural integrity of rail components but also streamline production processes, enabling manufacturers to meet tight deadlines and growing market demands. By adopting cutting-edge technologies, manufacturers can increase the precision of welds, reduce production costs, and improve the overall efficiency of rail systems. Global procurement specialists should prioritize partnerships with companies that emphasize innovation in their welding processes and product offerings, ensuring a long-term, reliable supply of high-quality rail fasteners and accessories.

Ultimately, reliable procurement hinges on a comprehensive understanding of the market leaders who demonstrate excellence in both traditional and innovative welding techniques. Evaluating potential suppliers requires careful consideration of their production capabilities, technological advancements, and commitment to technical service and support. By aligning with manufacturers that prioritize both service and innovation, procurement professionals can secure high-quality rail solutions that not only meet current requirements but also anticipate the future needs of the global rail industry.

How To Evaluate Submerged Arc Welding Rail Where Service Meets Innovation Market Leader

| Criteria | Description | Importance (1-5) | Evaluation Score (1-10) |

|---|---|---|---|

| Welding Speed | Rate of advancement during welding operations. | 5 | 8 |

| Weld Quality | Assessment of the integrity and appearance of the weld. | 5 | 9 |

| Material Compatibility | Ability to weld different types of metals effectively. | 4 | 7 |

| Equipment Reliability | Frequency of breakdowns and maintenance requirements. | 4 | 8 |

| Cost Efficiency | Total cost of ownership including maintenance and operation. | 5 | 6 |

| Safety Features | Incorporation of safety measures for operators. | 5 | 10 |

Why Invest In Submerged Arc Welding Rail Leads the Global Market Delivers Unmatched Quality

M

Michael Johnson

These items are top-notch! The professionalism of the customer service team made a significant difference in my buying experience.

04

June

2025

E

Ethan Jones

This product is a game-changer. The quality is remarkable, and the customer support is top-tier!

31

May

2025

J

James White

The support staff was phenomenal. They provided detailed answers and made me feel very comfortable.

18

May

2025

M

Mason Parker

Support was exceptionally helpful! Their professionalism made a huge difference.

21

May

2025

N

Nora Mitchell

This product has truly impressed me! The quality is remarkable.

12

June

2025

D

Daniel Miller

Quality is outstanding, and the team behind it is equally impressive. They addressed my concerns with utmost professionalism.

15

June

2025