Welded Rail Clamps (Clips) For heavy-duty Gantry Cranes, Jib Cranes, STS Container Cranes, RMQC, EOT cranes etc.

General Description

SINCHOLD's innovative design allows the upper clamp to be movably positioned on the fastening end. By adjusting the position of the upper clip relative to the fastening end, it can easily adapt to varying track installation spacing requirements.

Key Features

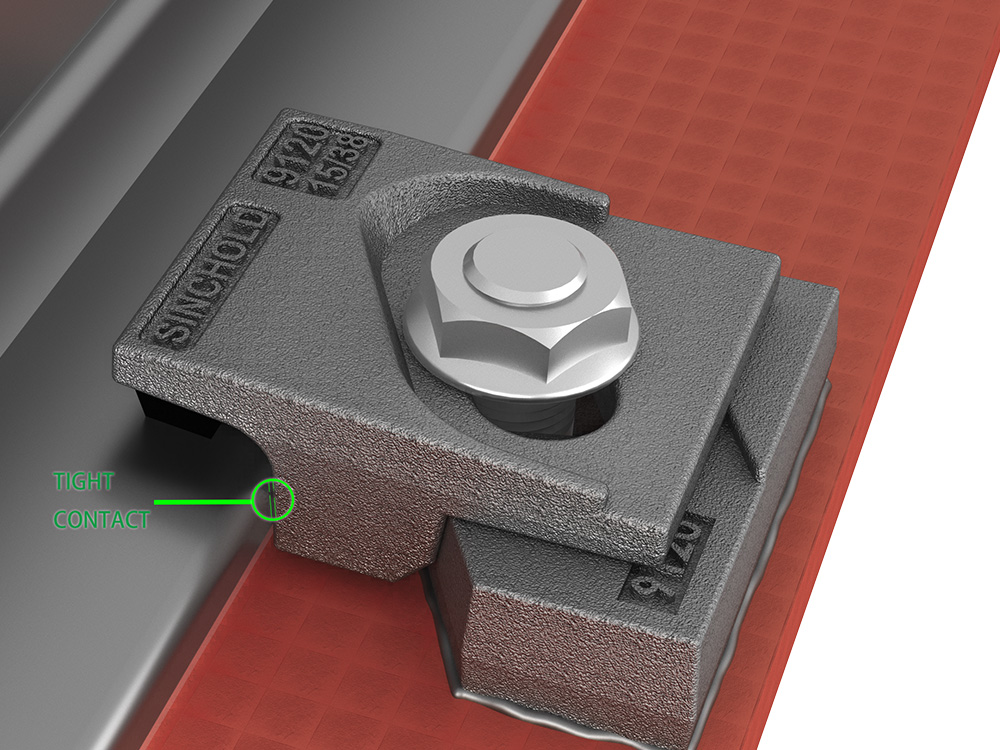

● Long Oval Hole: The rail clamp is designed with an elongated oval hole, enabling precise adjustment during installation.

● Sloped Hole and Stop Block: The sloped hole, paired with a stop block, effectively prevents the rail clamp from shifting after tightening, ensuring secure and stable positioning.

● Convenient Adjustment: This design provides flexibility for side adjustments during installation or maintenance of crane tracks, simplifying the process and saving time.

Benefits

The adjustability of the rail clamp is one of its standout features, offering:

● Flexible Adjustment: Adapts to different installation needs with ease.

● Strong Adaptability: Suitable for a wide range of track configurations.

● Ease of Installation and Maintenance: Simplifies adjustments and reduces downtime.

This design ensures the safe and efficient operation of rail transit systems, providing a reliable solution for track installation and maintenance.

Each set of SINCHOLD rail clamp is integrated with a vulcanized rubber nose (pressure block). Thanks to its elastic properties, the rubber nose absorbs and disperses impact forces on the track, providing effective damping. This helps reduce track vibration and noise, enhancing the smoothness and comfort of the ride. The rubber nose works in conjunction with the rail clamp to securely fix the track, preventing displacement or shaking. This ensures the stability and safety of the track, minimizing the risk of accidents caused by track loosening.

Applications

The rubber nose is widely used in various industries, including railways, lifting equipment, steel mills, power plants, ports, and metallurgy. It is particularly critical in applications that require withstanding significant impact and vibration, such as railway tracks and crane tracks.

Customization Options

SINCHOLD offers a variety of rubber nose with upper clamp combinations to ensure compatibility with over 70 different rail profiles available on the market. Please reach out to us for better selection of the ideal rail clamp solution for your specific needs.

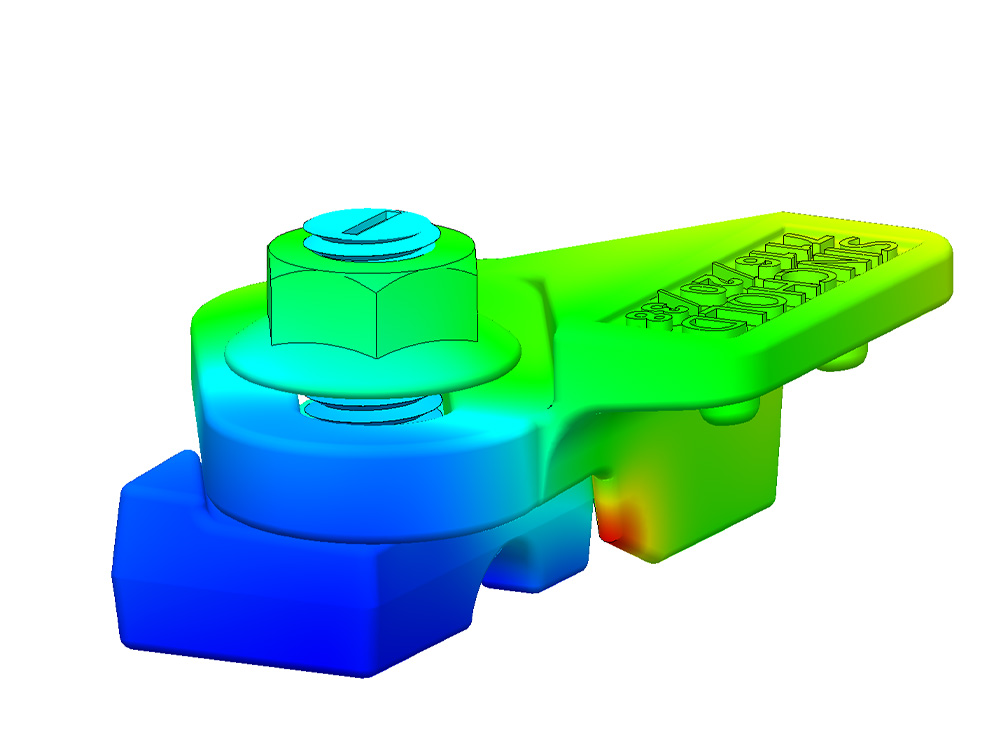

SINCHOLD rail clamps are designed to be compatible with nearly all rail profiles available worldwide. After undergoing 3 million fatigue tests, our rail clamps and their accessory parts showed no signs of cracks, significant deformation, or other damage. Their mechanical properties have been rigorously tested and certified by world-renowned professional laboratories specializing in track construction, ensuring exceptional performance and reliability.

SINCHOLD rail clamps are manufactured using advanced forging techniques. During the forging process, impact force or pressure is applied to deform the metal between the upper and lower dies (anvil blocks), shaping it into the desired form. This method is particularly suitable for rail clamps with simple shapes and larger dimensions.

For rail clamps with complex shapes and high dimensional accuracy requirements, we employ a closed-die forging process. In this method, the metal blank is compressed and shaped within a precision forging die cavity, ensuring the final product meets exact specifications.

Regardless of your requirements, SINCHOLD has the expertise to deliver tailored solutions. Please contact us for further consultation.